Erwan

45 Cal.

When writing this, do you mean that we won't see Maria and her nice work anymore?Hi,

I posted this for Maria.

Hello All,

Well here's what everyone has been waiting for... The final pictures.

When writing this, do you mean that we won't see Maria and her nice work anymore?Hi,

I posted this for Maria.

Hello All,

Well here's what everyone has been waiting for... The final pictures.

Absolutely stunning job! Well done! Very happy to hear you will be continuing to post on subsequent builds. You have made my Monday mornings for the last 6 months! Thank you!Hi,

I posted this for Maria.

Hello All,

Well here's what everyone has been waiting for... The final pictures.

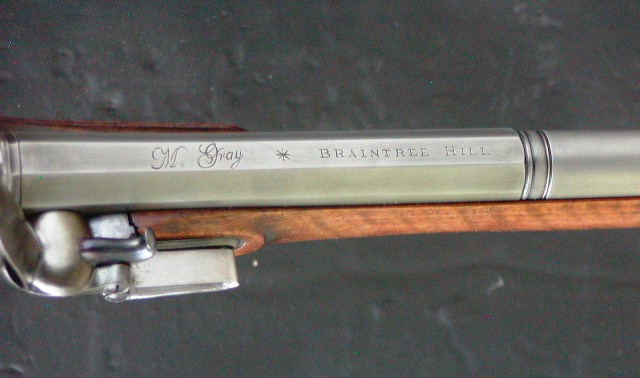

Man has it been a journey. Sometimes I have to pinch myself and ask if this is real. The best part? It is! There are a few little things I'd fix and change or wish I had done differently, but overall I'm definitely proud of myself. I couldn't of done this without having such an incredible teacher and mentor in Dave.

All the engraving is done by him, as that was a skill I did not have time to master with the deadline I had to work with.

I'm definitely NOT going to stop building although college will shorten the amount of time I have free. Already there are four orders in for this summer I will be building for folks (two Short Land Pattern Brown Besses, one Long Land, and one Eliot Carbine). The goal by the end of the summer is to be able to build a historically correct musket by myself without any guidance. I will be following in Dave's footsteps and posting updates throughout the summer on those builds so everyone who has followed this project has something to look forward to.

I would also like to say a huge thank you to everyone who has followed and supported this project. Your endless support and encouragement has never failed to bring a smile to my face. Thank you all for following along.

-Maria

Maria,I will baby this at events as much as I can within the bounds of historical accuracy. Of course, the whole point is to use it! It will not be a wall hanger so it will be well used and well loved.

There is hope for the world, after all!Hi,

Maria came over today and was in full 18th century dress. She made it look good compared with the over fed middle aged reenactors out there who try to represent starved continentals. Anyway, we made her ramrod pipes today. During our previous session, I taught her about steel, brass, and silver alloys, and how to heat treat them. Today, she learned how to solder. We started by cutting out rectangles of mild steel sheet to make the pipes. In our case the forward pipe is 27/64" inside diameter, the middle pipe is 3/8" inside diameter, and the rear pipe is 5/16" in diameter. That is consistent with original English fowlers from this period. She cut the rectangles and then embossed raised ribs on the ends. We use the methods taught to me by Kit Ravenshear using a little plate with a groove filed into it and a cold chisel.

We planned for 1/4" tabs on each side of the pipes for the pins. She formed those tabs next.

I had to tell her "whomp that pipe, don't give it a love tap. She whacked it accordingly.

After forming the tabs, we cleaned them up with files and sandpaper, preparing for soldering and formed the pipes around the appropriate sized drill bits. Then we soldered the tabs together.

Then she cleaned up the ends of the pipes and removed any burrs on the ends with a counter sink so they would not be sharp and scrape the ramrod.

She then filed and cleaned up the pipes. Next we cut off the tang from a cast steel rear pipe.

Then she soldered the tang on to her rear sheet steel pipe. She embossed a ring on the rear of that pipe about 1/8" forward of the end giving it a section to attach the cast tang. We then soldered the tang on to the rear pipe.

Maria cleaned it up and here are her set of pipes.

dave

Enter your email address to join: