- Joined

- Nov 26, 2005

- Messages

- 5,213

- Reaction score

- 10,839

Hi,

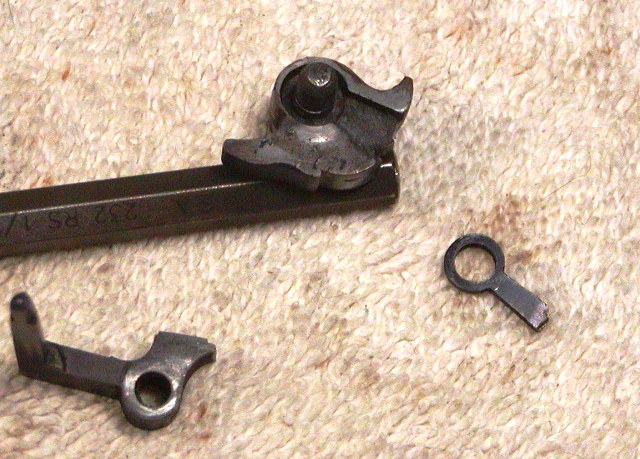

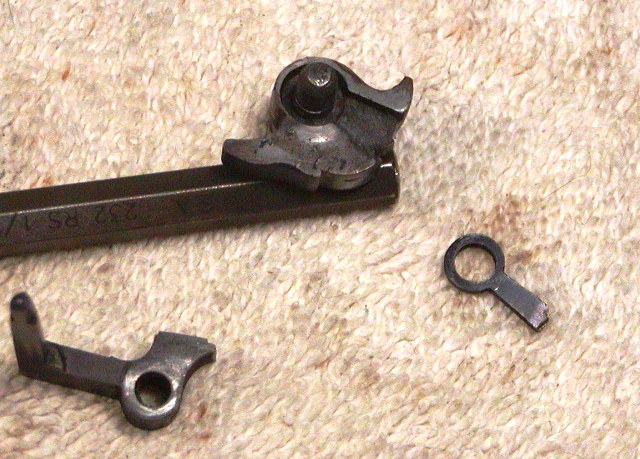

I got another project checked off. A few years ago, Dave Price gave me a bin of old original locks in various states of disrepair. He didn't think he would ever be able to use them and wondered if I would like them. I said yes immediately and I have worked through that bin over the years using bits and pieces of the locks for repairs, restorations, and new lock projects. Almost all of it is gone with almost nothing wasted. In the batch were two locks that were almost complete. One I believe is a 17th century German or Dutch flintlock without any internal bridle. The other was a lock by William Grice probably from the 1770s. I've resurrected the Grice lock and turned it into a great sparking and working flintlock. Here are the parts of the lock at the start.

I cleaned them up and had to add a sear spring from a Siler and replace all the screws. I recut the ovalo border on the lock plate and flint cock, re-engraved "GRICE" on the lock plate, and did some welding here and there to add metal lost to wear and corrosion. I heat treated all components The result came out well. The lock is fully functional and sparks like mad. I am not sure what I will do with it but it is a very attractive lock. Grice was a famous contractor to British Ordnance but he had a lot of civilian work as well. The tumbler has an early, what I call , "neck tie fly". It was used during the late 1760s and early 1770s. You can imagine how difficult it was to cut the channel for it into the tumbler. The other question, is why the fly? What was the lock used for? The only reason for a fly was to either use a set trigger or be able to adjust a simple trigger to a very light pull. So what was the lock used on. It is the size of a large Siler so it is hard to see it on a pistol. Was it mounted on a rifle with set trigger, something documented in England? I don't know but here it is.

enjoy.

dave

I got another project checked off. A few years ago, Dave Price gave me a bin of old original locks in various states of disrepair. He didn't think he would ever be able to use them and wondered if I would like them. I said yes immediately and I have worked through that bin over the years using bits and pieces of the locks for repairs, restorations, and new lock projects. Almost all of it is gone with almost nothing wasted. In the batch were two locks that were almost complete. One I believe is a 17th century German or Dutch flintlock without any internal bridle. The other was a lock by William Grice probably from the 1770s. I've resurrected the Grice lock and turned it into a great sparking and working flintlock. Here are the parts of the lock at the start.

I cleaned them up and had to add a sear spring from a Siler and replace all the screws. I recut the ovalo border on the lock plate and flint cock, re-engraved "GRICE" on the lock plate, and did some welding here and there to add metal lost to wear and corrosion. I heat treated all components The result came out well. The lock is fully functional and sparks like mad. I am not sure what I will do with it but it is a very attractive lock. Grice was a famous contractor to British Ordnance but he had a lot of civilian work as well. The tumbler has an early, what I call , "neck tie fly". It was used during the late 1760s and early 1770s. You can imagine how difficult it was to cut the channel for it into the tumbler. The other question, is why the fly? What was the lock used for? The only reason for a fly was to either use a set trigger or be able to adjust a simple trigger to a very light pull. So what was the lock used on. It is the size of a large Siler so it is hard to see it on a pistol. Was it mounted on a rifle with set trigger, something documented in England? I don't know but here it is.

enjoy.

dave