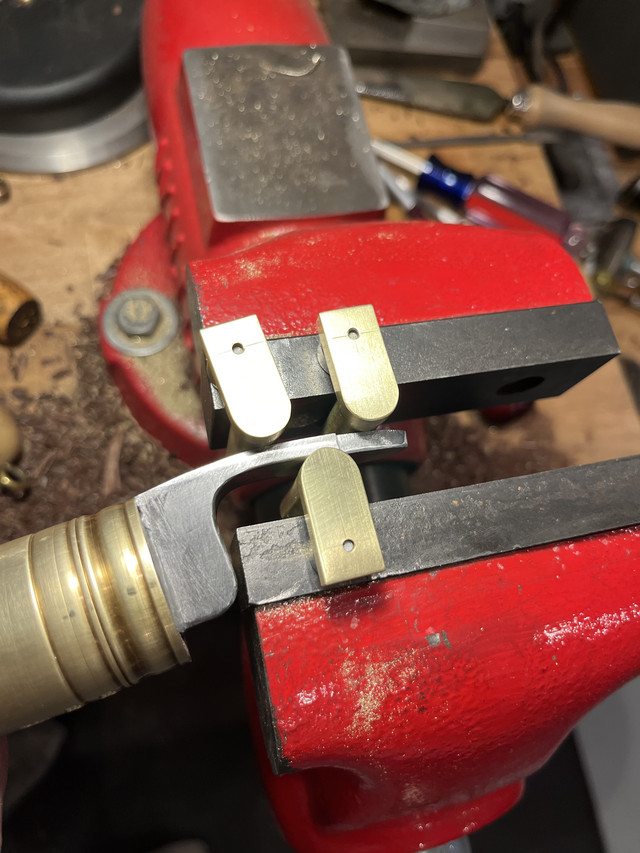

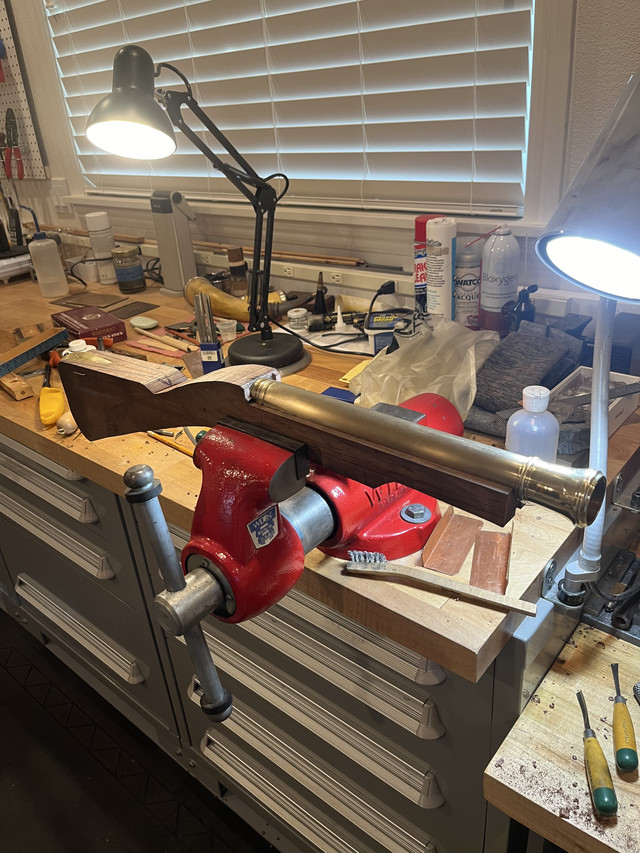

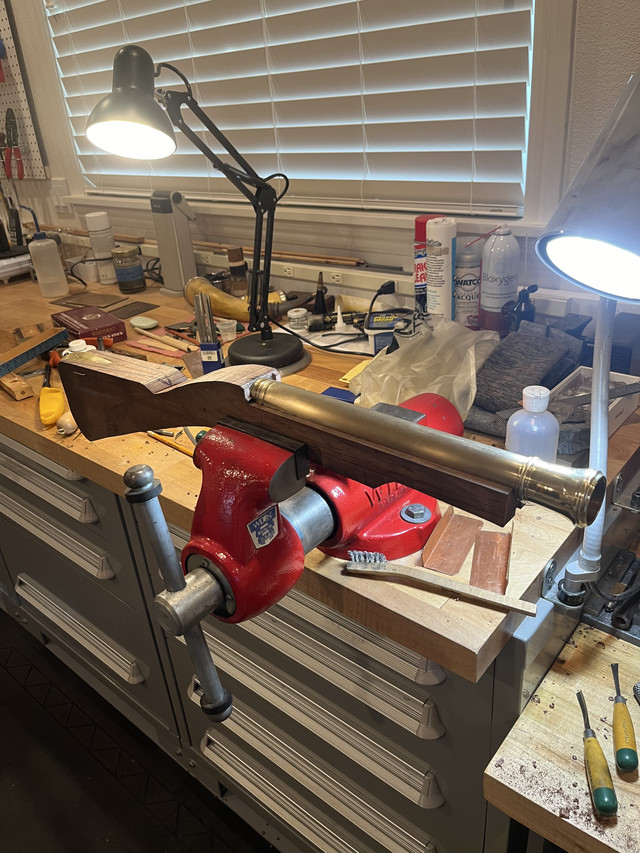

That’s really cool. I’ve been using chunks of metal and screwdrivers to use for those bending pins. I like yours way moreI was getting ready to bend the breech plug tang and was tired of doing it the same way I have always done it with a lead hammer and on a lead block. It works but is not a very controllable process in the greater scheme of things. So I stopped long enough to make these magnetically attached brass bending "bars" (for want of a better description). Brass 7/16" round stock is silver brazed to a brass arm made of 1/2" x 1/8" flat stock. A strong magnet is then screwed to the other end of the arm. These can be positioned easily on the vise and allow complete control of how much and where the bend occurs. Much better than whacking things with a lead hammer.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Copy of an original blunderbuss

- Thread starter davec2

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Mar 7, 2007

- Messages

- 730

- Reaction score

- 2,367

- Joined

- Mar 7, 2007

- Messages

- 730

- Reaction score

- 2,367

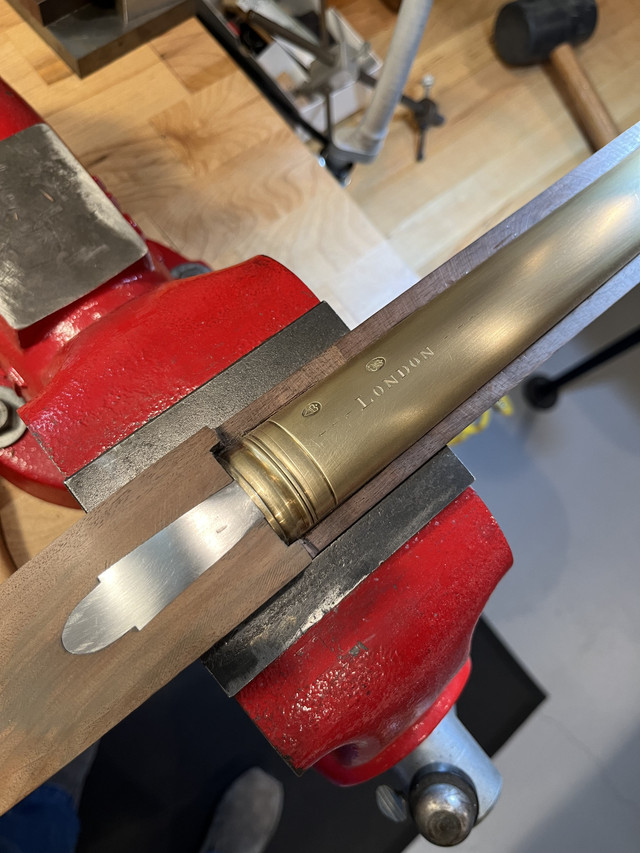

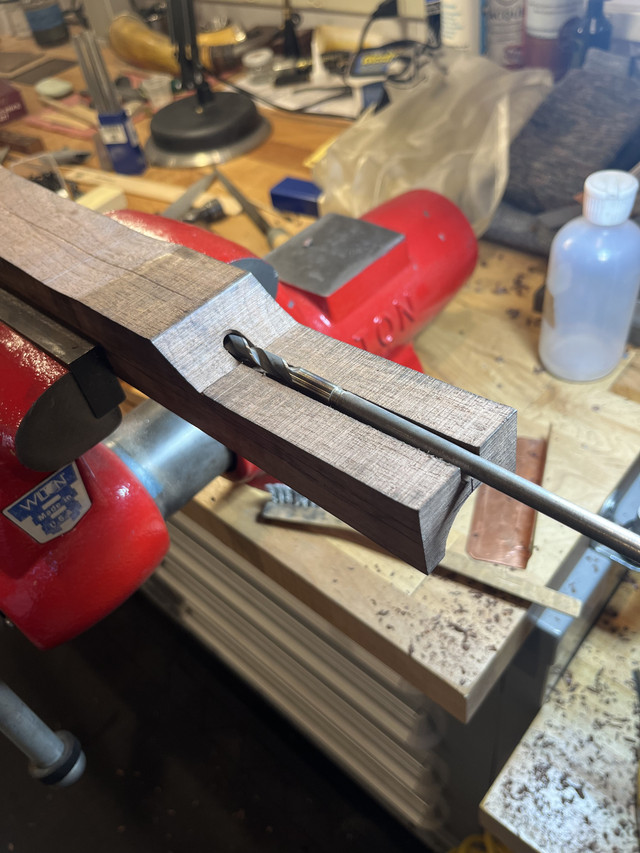

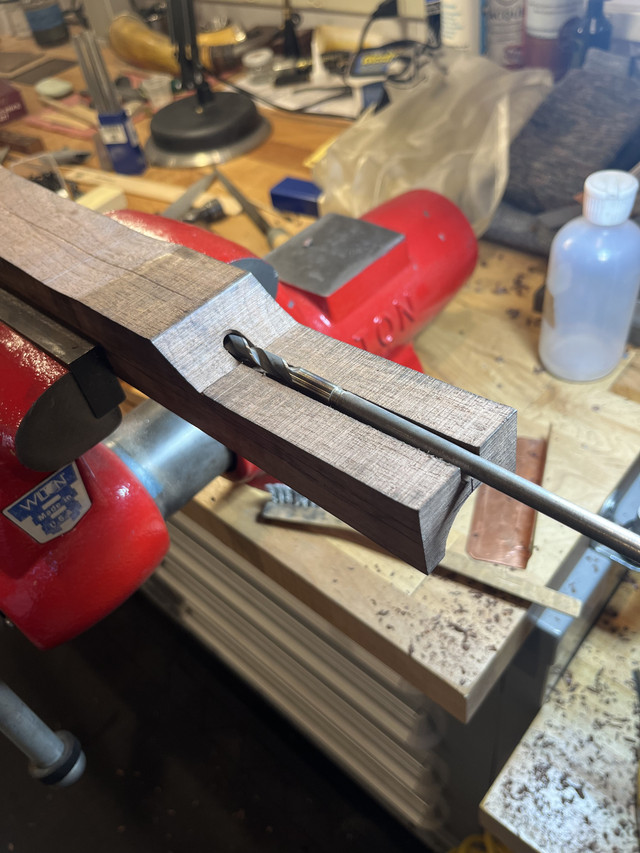

With most of the wood removed with the ball cutter, it only took a short while to finish the barrel inlet with hand tools and a Frank Mittermeir barrel rasp I bought 50 years ago....Also got the ram rod groove and hole drilled. As noted previously, since the barrel is only a foot long, all of this goes much quicker than it does on a long rifle....

- Joined

- Mar 7, 2007

- Messages

- 730

- Reaction score

- 2,367

Similar threads

Wanted - parts

WTB Blunderbuss barrel

- Replies

- 0

- Views

- 64

- Replies

- 28

- Views

- 1K

- Replies

- 7

- Views

- 1K

- Replies

- 10

- Views

- 2K

- Replies

- 12

- Views

- 728

Latest posts

-

Ignition Problems – No I idea what I am doing!!! Please help!

- Latest: oldschoolhunter55

-

-

-

-

-

-

-