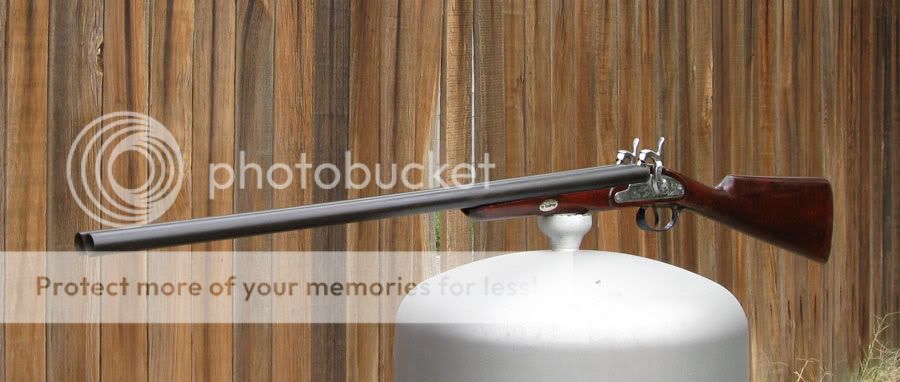

Perhaps this post should go in the The Gun Builder's Bench but I figure I'll put it here because many of you don't go to that area of the Forum.

When I started to rebuild the CVA I noticed that there is absolutely nothing that positions the barrels laterally except the face of the breech block.

While this does work, it is kinda like expecting a 2 foot long, 1" X 2" board to stick straight up when its placed on the floor resting on one end.

In the forearm, where the wedge passes thru the barrel underlug there is a giant milled cavity which more than clears the underlug/ramrod guide.

There is so much clearance that there is no way it can align the barrels with the stock.

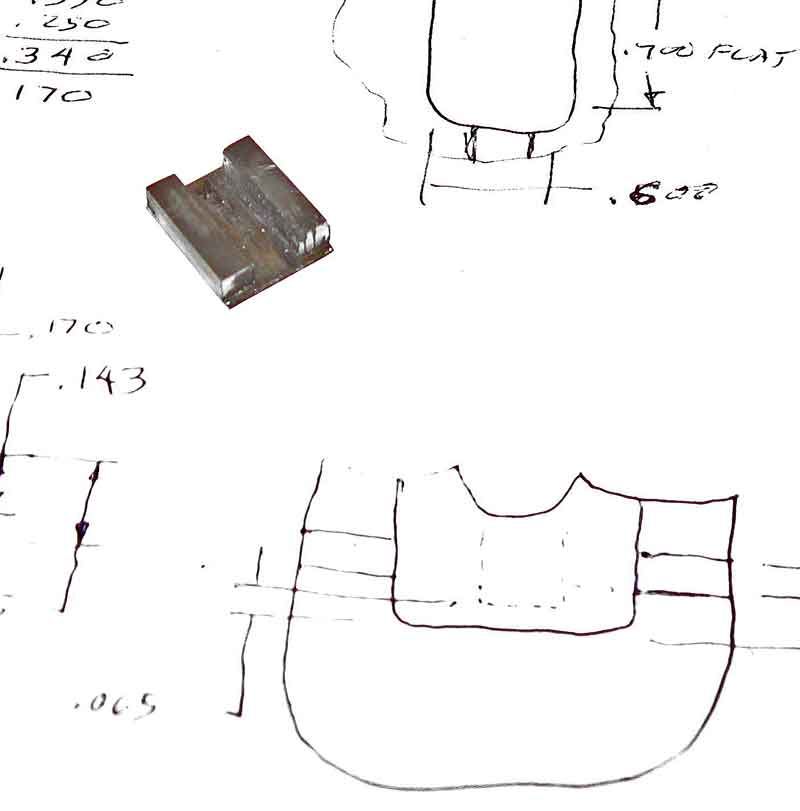

It is shown in this picture

After measuring the size of the milled cavity I found that something could be placed under the bottom of the wedge slot which could straddle the underlug without interfering with the wedge pin.

If this "something" fit the sides of the milled slot and straddled the underlug it would serve to guide the barrel and hold it central to the forearm.

The block could be milled out of a solid piece of bar stock but I don't have a milling machine so instead I made two pieces of steel from a angle bracket I picked up at Ace Hardware. It was .143 thick.

These two pieces were soldered to a piece of 1/32" steel sheet stock making the total height .175.

I found that the bottom of the barrel wedge slots in the stock were .180 from the bottom of the cavity so this .175 height made the top of the new block .005 under the wedge slots.

The width of my barrels underlug was .240 so I spaced the two blocks .250 apart for a .010 total clearance.

The soldered assembly looks like this

I measured the width of the milled cavity in the stocks forend and it was .600 so I made the 1/32" base of the locator .590 so it fits easily into the forend but can only shake sideways .010.

I still need to remove the flux from the soldering and I think I will Cold Blue all of the surfaces except the bottom with Birchwood Casey Perma Blue so it will look somewhat professional.

I will glue it in place with some epoxy on the bottom.

The assembled locator will look like this.

After assembling the barrels onto the stock with the locator installed I find almost no side to side movement of the barrels and the barrels breeches fit snugly against the breech block.

The few dimensions I mentioned were for my shotgun and others may be different so if you own a CVA Double barreled shotgun and decide you would like to make something like this you will need to accurately measure all of the important features like the slot size, depth, wedge location and barrel underlug width.