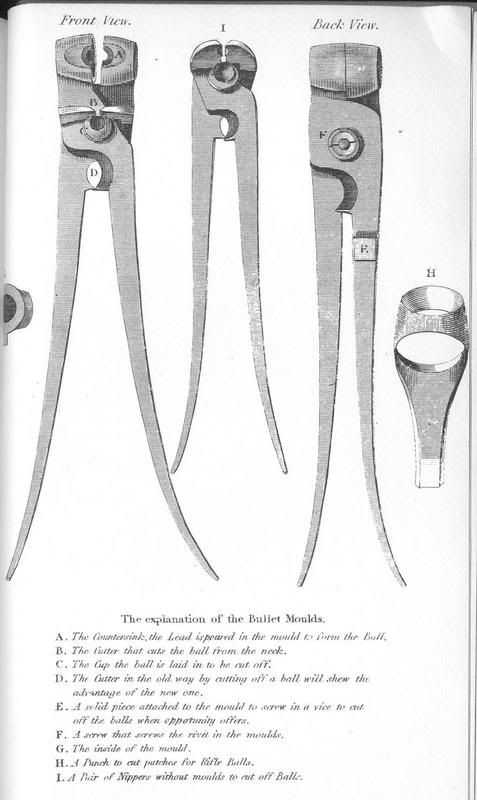

Tonight I cast 50 new .680 bullets the old school way, with the old fashioned handle mold without the sprue cutter. How is the easiest and prettiest way to get the sprue off? I used wire snips, and it came out acceptable for my purposes, but nothing like a modern round ball caster.

Other than the sprue being not as pretty as I like, they came out perfect. One of the reasons for that is I'm using a thermometer now. Casting bullets without a thermometer is like baking cookies without a thermostat on your oven. It can be done with some practice, but geez, save yourself the headaches of guessing. BTW I found a great thermometer for $12. All interested go to:[url] http://www.surpluscenter.com/[/url] and run a search for 1000F and it will pull up all there 200 to 1000F meters.

Other than the sprue being not as pretty as I like, they came out perfect. One of the reasons for that is I'm using a thermometer now. Casting bullets without a thermometer is like baking cookies without a thermostat on your oven. It can be done with some practice, but geez, save yourself the headaches of guessing. BTW I found a great thermometer for $12. All interested go to:[url] http://www.surpluscenter.com/[/url] and run a search for 1000F and it will pull up all there 200 to 1000F meters.

Last edited by a moderator: