- Joined

- Mar 7, 2007

- Messages

- 700

- Reaction score

- 2,170

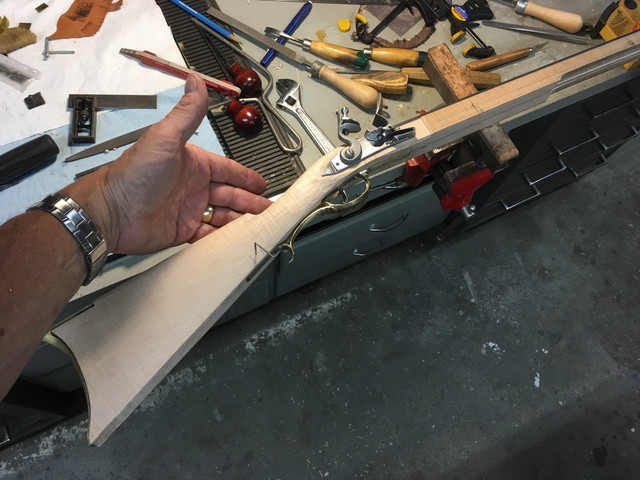

With the trigger and trigger plate installed, I could get the tang bolt hole drilled and tapped. Here I am using a long 6-32 tap. I didn't take pictures, but I also got both lock bolts drilled and tapped.

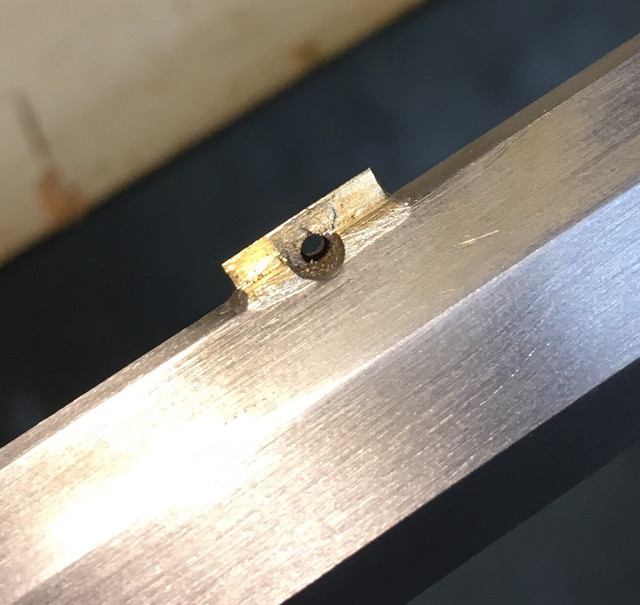

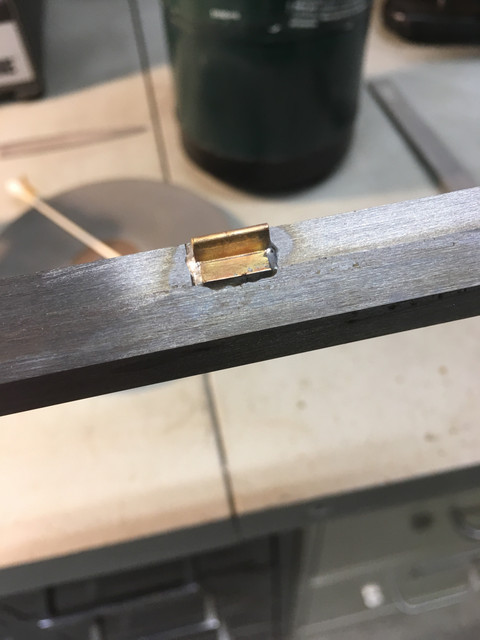

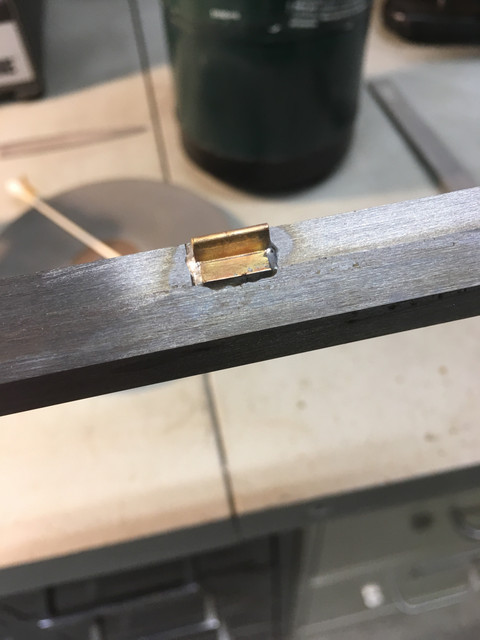

The barrel is so slender that I had to think about how I wanted to do the barrel lugs. I decided that, instead of the dovetail routine, I would just make up some tiny brass lugs and solder them to the barrel. I made them up out of 0.016 brass sheet, folded them, silver brazed the joint and then trimmed them to final size.

After trimming, I tinned them with Hi Force silver bearing solder (a fair amount stronger than lead solder but only melts at 475 F) and then installed them on the barrel.

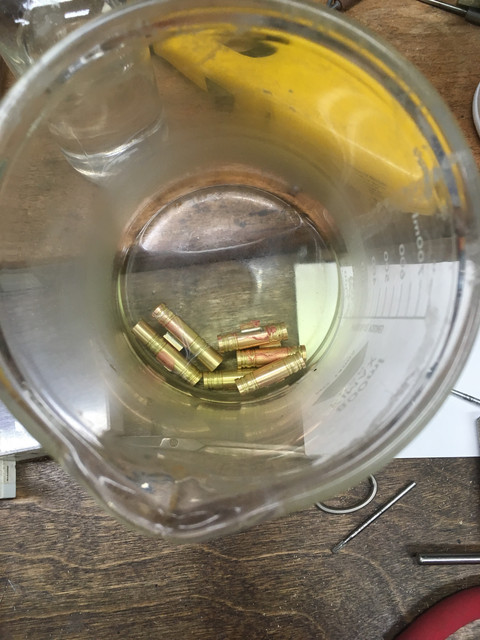

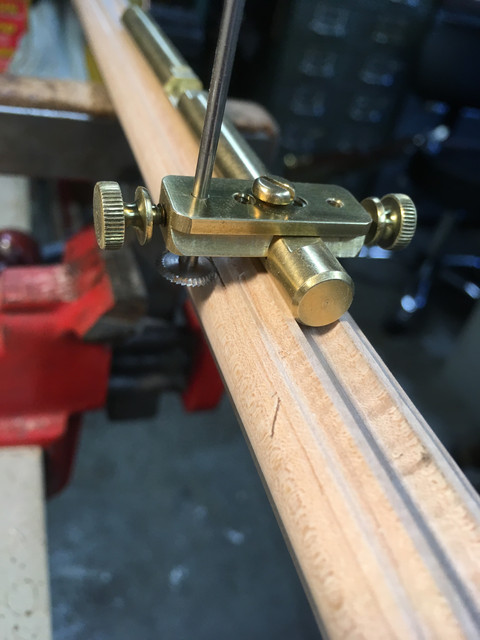

Will get them trimmed up and clean up before drilling them through the stock......And I may have a problem here. When I had Dave Rase inlet these barrels for me, I asked him to keep the web between the ram rod and the bottom of the barrel about 3/32" (0.093"). They actually came out a tad thinner so that doesn't leave me a lot of room with a 1/16" pin......we'll see how it plays out.

The barrel is so slender that I had to think about how I wanted to do the barrel lugs. I decided that, instead of the dovetail routine, I would just make up some tiny brass lugs and solder them to the barrel. I made them up out of 0.016 brass sheet, folded them, silver brazed the joint and then trimmed them to final size.

After trimming, I tinned them with Hi Force silver bearing solder (a fair amount stronger than lead solder but only melts at 475 F) and then installed them on the barrel.

Will get them trimmed up and clean up before drilling them through the stock......And I may have a problem here. When I had Dave Rase inlet these barrels for me, I asked him to keep the web between the ram rod and the bottom of the barrel about 3/32" (0.093"). They actually came out a tad thinner so that doesn't leave me a lot of room with a 1/16" pin......we'll see how it plays out.