- Joined

- Mar 7, 2007

- Messages

- 700

- Reaction score

- 2,177

Made a set of form blocks and contoured the brass pieces of the patch box to conform to the stock shape.

Making a patch box hinge for a normal size box is, if done in the traditional way, fairly time consuming and a little complicated. Several years ago I made a hinge by a different method and silver brazed it to the box parts. Although not formed from the parent material of the box lid and finial, it looks to me a lot like some box hinges that were separate and then riveted to the box parts on some original rifles. Be that as it all may, I decided to do the brazed method on this little box.

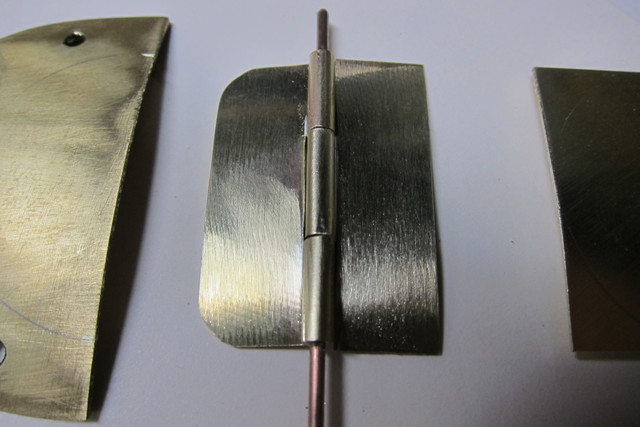

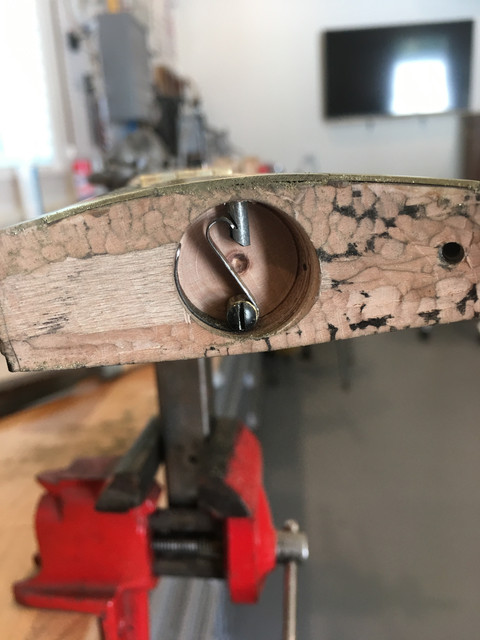

The lid is 1 inch wide and I had a small brass hinge just that wide as well. To insure that the lid and the finial are just as strong as if made from the parent material, I elected to hard silver braze the pieces and also make sure that there was an excellent fit between the hinge halves and their respective box pieces. Since both the box lid and finial had been contoured to fit the shape of the stock, the hinge had to be shaped to match the curve in order to get a tight braze joint. Here is a shaped half of the hinge and a photo showing the tight fit up to the box lid......(When I have to shape small parts like this with a file, I usually super glue the part to a small block of wood to do the work as in the picture here. Once the file work is finished, heating gently with a torch easily releases the part. I do the same thing for a lot of my engraving.)

Then the hinge halves are silver brazed to their respective parts.....

The box lid and finial are reassembled with the hinge pin.......

The box parts are drilled for the attaching screws and mounted in place for the start of the inletting......

Making a patch box hinge for a normal size box is, if done in the traditional way, fairly time consuming and a little complicated. Several years ago I made a hinge by a different method and silver brazed it to the box parts. Although not formed from the parent material of the box lid and finial, it looks to me a lot like some box hinges that were separate and then riveted to the box parts on some original rifles. Be that as it all may, I decided to do the brazed method on this little box.

The lid is 1 inch wide and I had a small brass hinge just that wide as well. To insure that the lid and the finial are just as strong as if made from the parent material, I elected to hard silver braze the pieces and also make sure that there was an excellent fit between the hinge halves and their respective box pieces. Since both the box lid and finial had been contoured to fit the shape of the stock, the hinge had to be shaped to match the curve in order to get a tight braze joint. Here is a shaped half of the hinge and a photo showing the tight fit up to the box lid......(When I have to shape small parts like this with a file, I usually super glue the part to a small block of wood to do the work as in the picture here. Once the file work is finished, heating gently with a torch easily releases the part. I do the same thing for a lot of my engraving.)

Then the hinge halves are silver brazed to their respective parts.....

The box lid and finial are reassembled with the hinge pin.......

The box parts are drilled for the attaching screws and mounted in place for the start of the inletting......