- Joined

- Mar 7, 2007

- Messages

- 700

- Reaction score

- 2,177

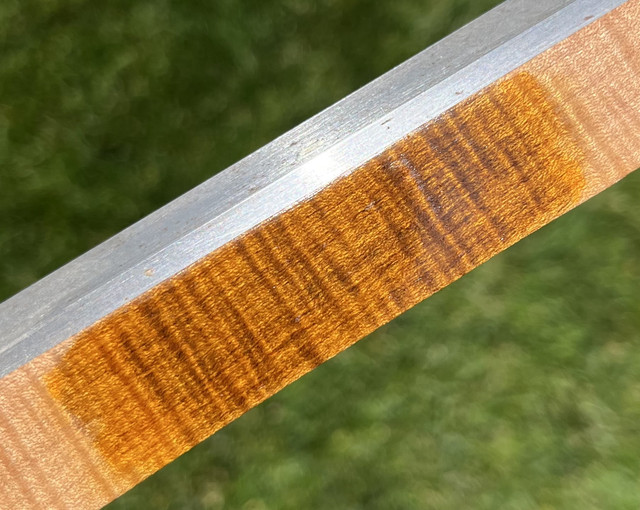

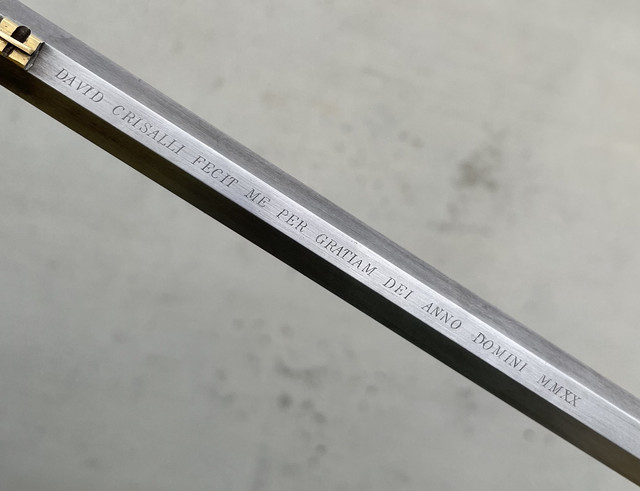

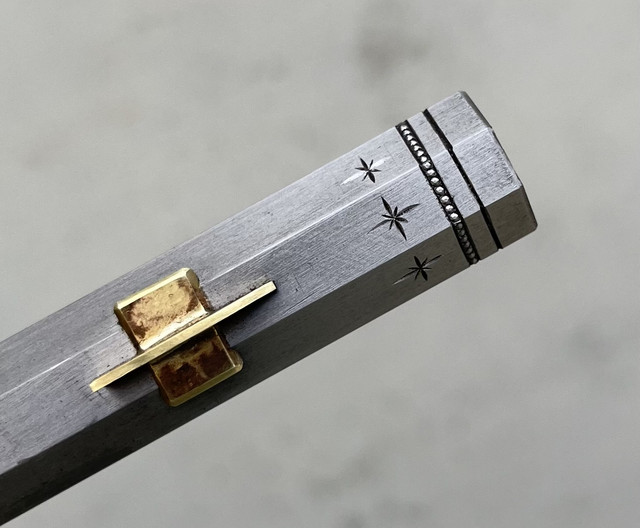

Today I had the opportunity to re-contour the "blob" of weld metal that I had to add to the tumbler to repair the broken half **** notch. I had to re-fit the sear, the fly recess, and the fly a bit as well. Here is the result.....

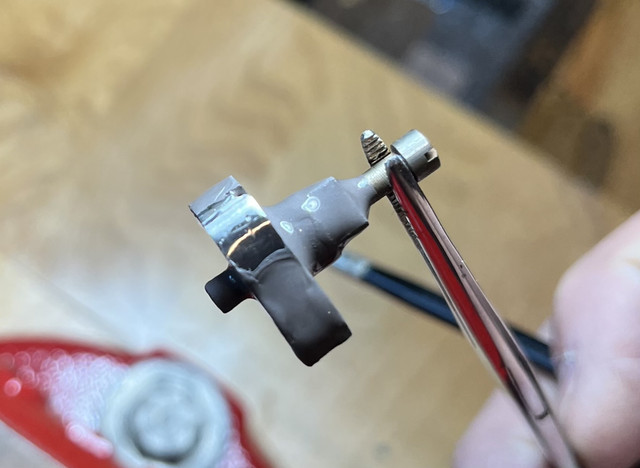

Since the new metal was not high carbon, I needed to case harden the area of new weld metal. However, I didn't want to add more carbon to the rest of the tumbler, so I covered all the rest of the surface with an anti-scaling compound I get from Brownells. I use this also for re-heat treating frizzens after engraving to keep the surface from acquiring any fire scale. Here I am painting the compound on the tumbler except for the weld repair area.

Letting the compound dry in the sun for a few minutes.....

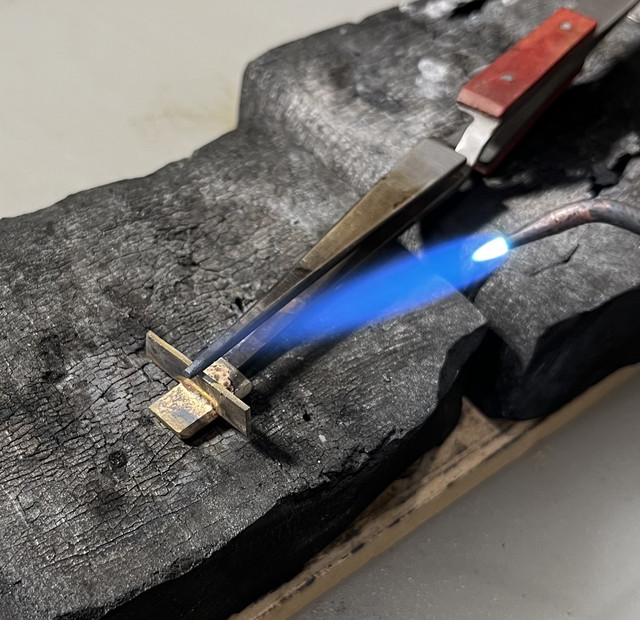

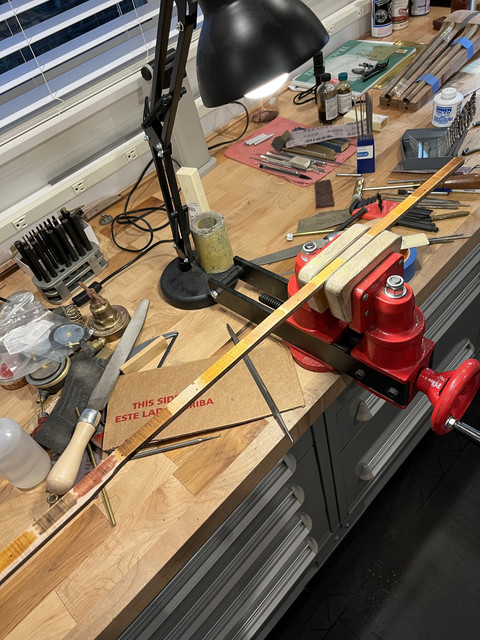

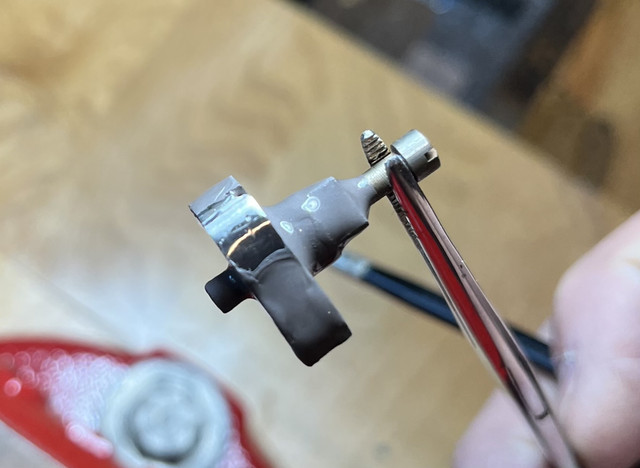

I don't have any pictures of the the next part of this procedure but I used a propane torch and Kasenit to case harden the weld repair area. When I do this for screw heads and triggers, etc, I quench the part in brine water from a bright orange heat . After that I do not draw / temper the part because it only has a surface case on it and the core is still soft. In this particular case, the majority of the tumbler is made of high carbon steel and, when I quenched it, it became hard all the way through. So it needed to be drawn back some. (I think the part originally broke because it was not drawn sufficiently.) To do this in a little more controlled fashion, I put both the sear and the tumbler in my melting furnace and slowly brought the temperature up to 565 F letting the parts soak at that temp for about a half an hour. At Dave Pearson's suggestion, I did both the sear and the tumbler at the same time so that they will be of equivalent hardness when done.

The tumbler and the sear out of the furnace......

The reassembled ...and now working again lock......

I also had a chance today to make and install the tiny rear sight.....I will post pictures of that tomorrow....

Since the new metal was not high carbon, I needed to case harden the area of new weld metal. However, I didn't want to add more carbon to the rest of the tumbler, so I covered all the rest of the surface with an anti-scaling compound I get from Brownells. I use this also for re-heat treating frizzens after engraving to keep the surface from acquiring any fire scale. Here I am painting the compound on the tumbler except for the weld repair area.

Letting the compound dry in the sun for a few minutes.....

I don't have any pictures of the the next part of this procedure but I used a propane torch and Kasenit to case harden the weld repair area. When I do this for screw heads and triggers, etc, I quench the part in brine water from a bright orange heat . After that I do not draw / temper the part because it only has a surface case on it and the core is still soft. In this particular case, the majority of the tumbler is made of high carbon steel and, when I quenched it, it became hard all the way through. So it needed to be drawn back some. (I think the part originally broke because it was not drawn sufficiently.) To do this in a little more controlled fashion, I put both the sear and the tumbler in my melting furnace and slowly brought the temperature up to 565 F letting the parts soak at that temp for about a half an hour. At Dave Pearson's suggestion, I did both the sear and the tumbler at the same time so that they will be of equivalent hardness when done.

The tumbler and the sear out of the furnace......

The reassembled ...and now working again lock......

I also had a chance today to make and install the tiny rear sight.....I will post pictures of that tomorrow....