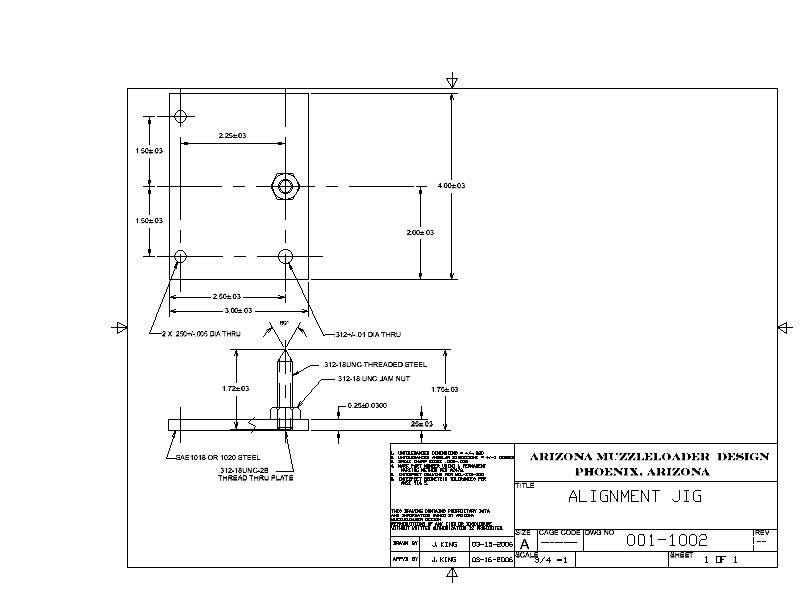

I know most of you know what this is, and what it is used for. I know some of you also have built your own, but for those who need something to do, and enjoy working to Engineering style drawings, I offer you a present. (Hopefully you can read it).

As I am giving it to you, obviously it isn't for sale so Claude and the other moderators shouldn't get too upset.

For those who don't know what it is, this tool is used in conjuction with a drill press by aligning the pointed part with the drill spindle. Once aligned, you bolt it in place to the table.

You then make a small indentation with a center punch at the location where you want the drill to come out (lets say the trigger plate right in front of the trigger).

Center punch the location where you want the drill to go in (lets say on the barrel tang an inch behind the breech).

With the rifle and its trigger plate indentation located on the pointed shaft, move the rifle until the tangs indentation lines up with the drill and proceed to drill thru the tang and about half way thru the stock.

Now, reverse the rifle so the pointed shaft is located in the tang hole and start the drill in the trigger plate indentation, drilling thru the trigger plate and thru the stock to intersect the first hole you drilled.

Like magic, you now have the thru hole in the tang, trigger plate and stock all perfectly aligned.

Oh, this first drilling should be done with the tap drill for the screw, not the clearance hole sized drill.

Zonie

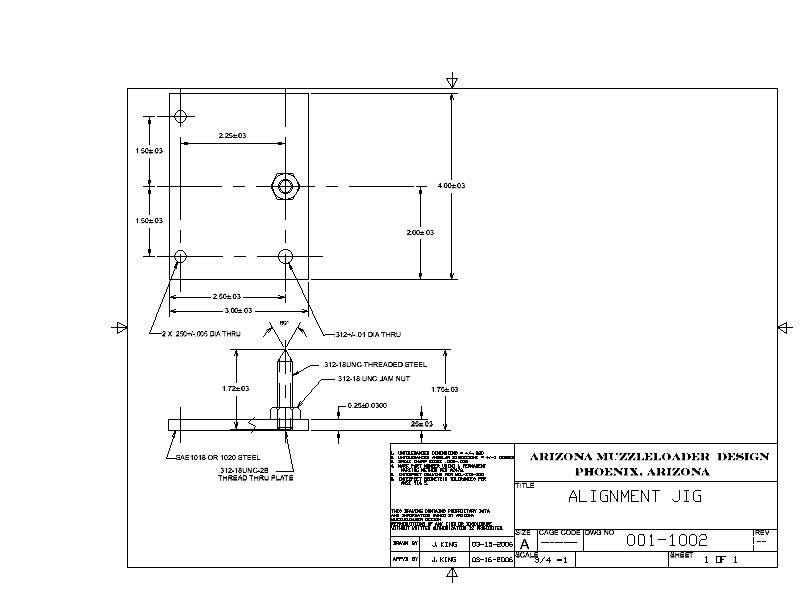

As I am giving it to you, obviously it isn't for sale so Claude and the other moderators shouldn't get too upset.

For those who don't know what it is, this tool is used in conjuction with a drill press by aligning the pointed part with the drill spindle. Once aligned, you bolt it in place to the table.

You then make a small indentation with a center punch at the location where you want the drill to come out (lets say the trigger plate right in front of the trigger).

Center punch the location where you want the drill to go in (lets say on the barrel tang an inch behind the breech).

With the rifle and its trigger plate indentation located on the pointed shaft, move the rifle until the tangs indentation lines up with the drill and proceed to drill thru the tang and about half way thru the stock.

Now, reverse the rifle so the pointed shaft is located in the tang hole and start the drill in the trigger plate indentation, drilling thru the trigger plate and thru the stock to intersect the first hole you drilled.

Like magic, you now have the thru hole in the tang, trigger plate and stock all perfectly aligned.

Oh, this first drilling should be done with the tap drill for the screw, not the clearance hole sized drill.

Zonie