I tend to agree. Claud Fuller and Arcadi Gluckman who were probably the foremost of US military arms scholars in their time, both used the designations "M1795, '08, '12 and so on, and many reaearchers and students of these arms, including myself, have also used them even though they're not really correct. But, these "model designations", although incorrect, are handy when we are discussing muskets of particular periods and types and I guess we tend to overlook it from time to time. I for one, not being an expert, need all the help I can get when trying to answer a question about a particular gun and since I can't remember every detail about a certain gun find these model numbers useful in looking up something I couldn't remember. Fuller even has a "Special Model 1795" musket listed that included changes found in later patterns, including the combless stock of the M1816.

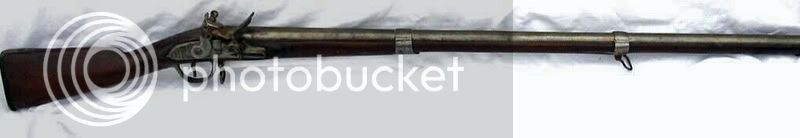

From what I have read and observed, the muskets adopted by the US military from 1795 through 1812 were patterned directly from the M1763 French musket used in our Revolution. Slight changes were made such as lock dimensions and others too detailed to go into here through to the 1812 variant. In 1808, due to so many variations between the two National Armories and the contractors, a new "standard" musket was introduced and pattern muskets were passed out to the armories as well as the contractors so that their output would be the same as much as possible. According to Gluckman, some of the changes in these arms conformed to the M1777 French musket. By 1812, it was found that there was still a great lack of uniformity in those muskets made by the contractors. New pattern muskets were then made for a new "model", the so-called M1812. Not only were the contractors to make the new musket on this pattern, they were forced to make some of the changes while still fulfilling the 1808 contracts. That's one of the reasons why so many of the muskets made during this period don't conform to a certain pattern or model. As VA MANUF. said, the Springfield production can be broken down into 3 groups. Actually, the Harpers Ferry production can be broken down, as well as those made by contractors. Flayderman himself has broken each model year down into groups. It can be very confusing. Add to that the fact that many of the existing muskets from this period have had field or armory repairs and some were made with parts from a different model.

The M1816 was an attempt to perfect the musket and get away from the ongoing problems with so many variations coming from the various armories. But, it was still a "Charleville Pattern" musket. Some of the changes had already been incorporated on some of the muskets of the 1812 pattern in the few years before the adoption of the M1816. The biggest change in this model was in the lock, which was closely patterned after the French Model 1777. The mountings still conformed to the M1763 and the stock was changed by removing the comb at the wrist. In 1817, the brass pan used on the M1777 replaced the iron one on the US muskets, although the iron pan was used until existing stocks were used up.

The M1835 (or M1840 if you lean that way) was patterned with minor changes after the French M1822. And the M1842 percussion musket was merely the '35 with a percussion lock.

As for the arms produced at Springfield and Harpers Ferry being different, that is very true. It shouldn't have happened, especially since both armories employed highly skilled craftsmen from the New England and Pennsylvania arms trade. But there were various problems at the Ferry; health issues among employees, quality control and outright crookedness existing at the supply end (iron and wood suppliers), family and local control of the Armory and most of all, the reluctance of the armory administrators to adopt new technology and machinery that would have insured uniformity and greater production. Although John Hall had been making interchangeable rifles at the Ferry for years, it wasn't until 1845 when the M1842 production started that muskets made there were fully interchangeable. For years, the armorers fought against the machines that Springfield had embraced, simply because of the pride they had in their skills and the higher pay they received. They didn't want to become mere "machine tenders". I will say one thing, for years all the pattern muskets used in production at both armories as well as by the contractors were made at Harpers Ferry and in one report I've read it was mentioned that the workmen there made extremely high quality pattern arms. They just seemed to fall down when it came to production runs. I forgot to mention above that there was some skullduggery going on among some of the inspectors as well. There were some complaints by Army officers that they had received some muskets that didn't even have the touchholes bored out. This made it to the Secretary of War who asked the superintendent just how did these muskets pass proof if there were no vents through which fire could be communicated to explode the proof charges? Roswell Lee at Springfield did the best he could to help out at Harpers Ferry by trading workers, materials and ideas, and it helped, but not enough to overcome all the problems at the Ferry.

I'm afraid I got a little longwinded here.

You'll have to forgive me. There's no one here at the house to talk about this stuff with. For some reason my wife just doesn't get into this.