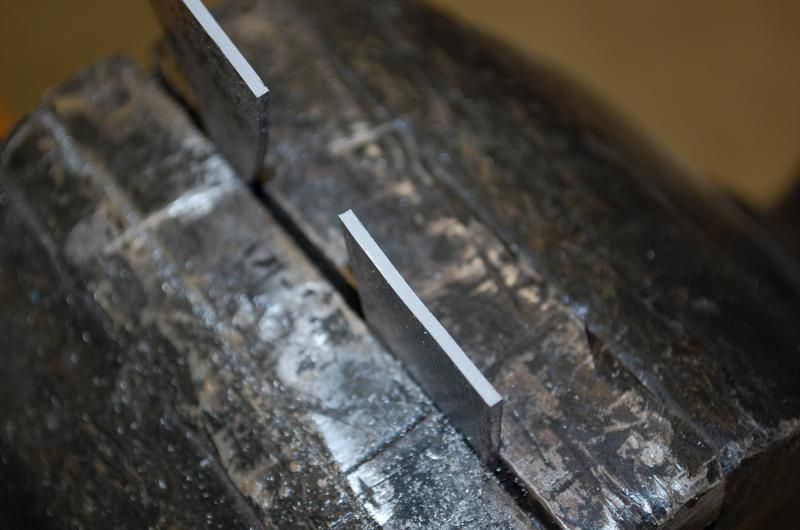

After last weeks conversation about blister steel I decided to go ahead and make some. As you can see in the lower photo the 1/16" plates came out with some interesting colors and also a fair number of the so called blisters.

These plates were carburized in a wood/bone charcoal mixture for 3 hours at 2000 degrees F. The material seems to harden fine and breaks clean with a nice uniform structure. I made a small spring for a test piece and it seemed to work fine as well.

So, I went ahead and made a penny knife out of it. Not as fancy as Wick's, but seems to have come out OK.

The handle is about 4.25 long and is turned out of a scrap of rosewood I had lying around.

These plates were carburized in a wood/bone charcoal mixture for 3 hours at 2000 degrees F. The material seems to harden fine and breaks clean with a nice uniform structure. I made a small spring for a test piece and it seemed to work fine as well.

So, I went ahead and made a penny knife out of it. Not as fancy as Wick's, but seems to have come out OK.

The handle is about 4.25 long and is turned out of a scrap of rosewood I had lying around.