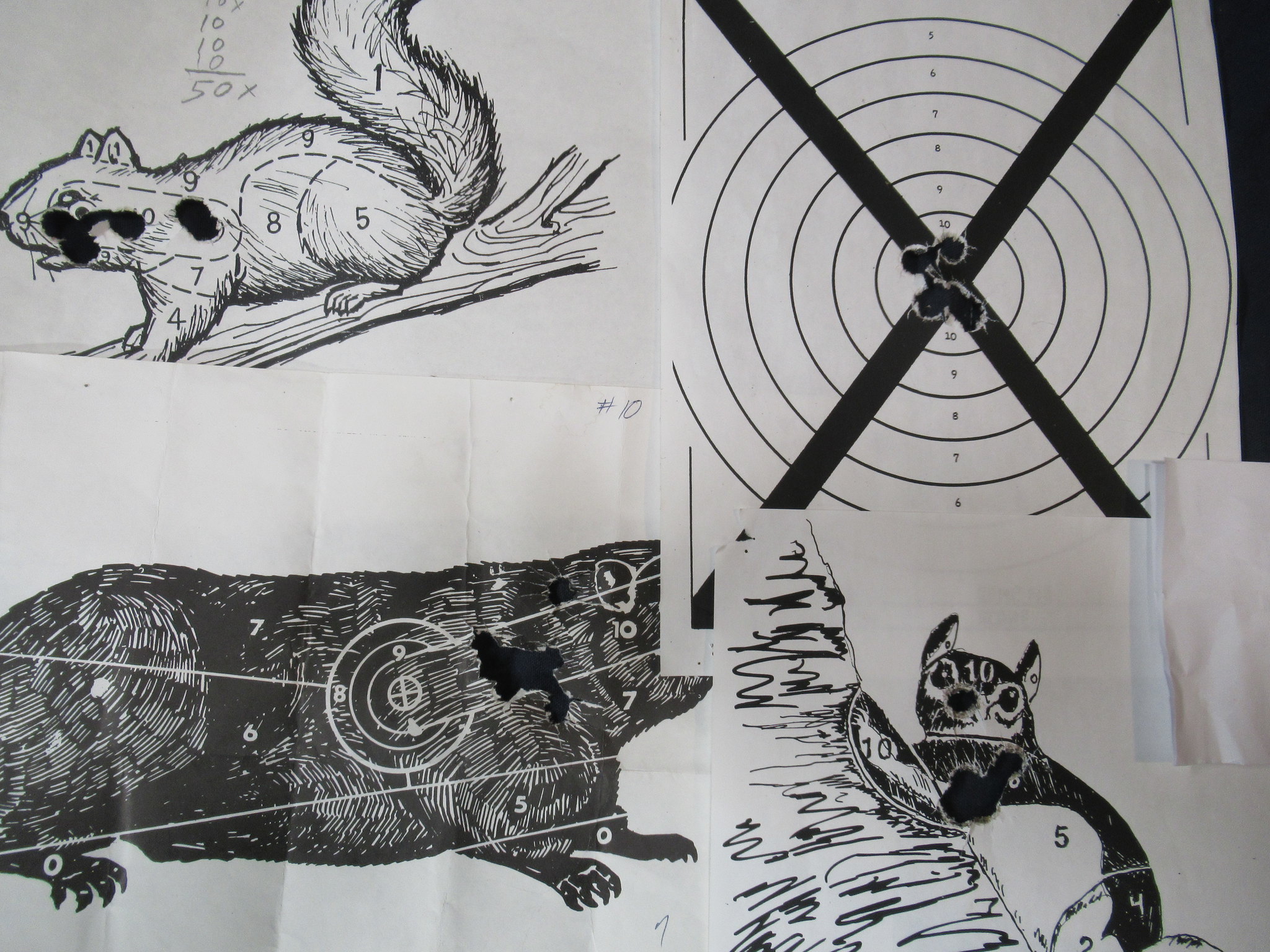

Recently picked up a used Lyman GPR on my first outing I couldn't hit the broad side of a barn (10-inch groups at 50 yards). after about 20 shots down range and adjusting my load, I finally walked down range and immediately noticed nearly every single patch was completely shredded, I wasn't encountering a tremendous amount of force when loading .530 ball and red/blue pillow ticking lubed with 1-6 ballistol/water . It was snug but not crazy tight (I load my pedersoli kentucky with a lot more force on the short starter).

Still learning the ropes with muzzleloading and I've read that GPR's tend to be sharp from the factory, the gentleman I purchased it from included half a box of balls so it's likely that's all it had ran through it prior to sale (Seems in very pristine condition)

So where to start with this problem?

Still learning the ropes with muzzleloading and I've read that GPR's tend to be sharp from the factory, the gentleman I purchased it from included half a box of balls so it's likely that's all it had ran through it prior to sale (Seems in very pristine condition)

So where to start with this problem?