Bookie

40 Cal.

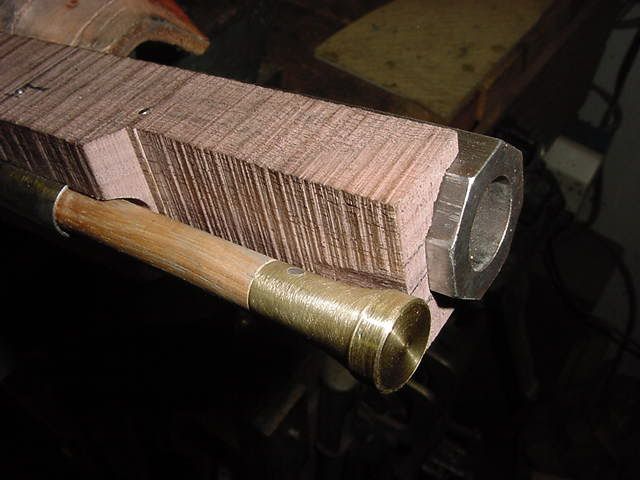

The wheelie is finally getting underway. 1st Photo: The lock plate has been remodified at the upper rear portion of the tail to more resemble the original. The .62 cal. barrel is inlet and pinned, but the front 3/5ths still needs to be turned 1/2 round. The ramrod channel is carved and the hole drilled. The butt is half way profiled and you can see the round shape. 2nd Photo: Is the forearm being laid out so I can carve the ramrod channel. 3rd Photo: The stock is in my ramrod hole drilling fixture. Look closely and you can male out the 4 foot drill bit in place. The wood is STRIPED native Iowa walnut. The original that I am "copying" is a Dutch military carbine. Since my barrel is longer, the weapon will be a smooth rifle. Hope you enjoy the pics. Bookie