- Joined

- Nov 26, 2005

- Messages

- 5,223

- Reaction score

- 10,881

Hi Folks,

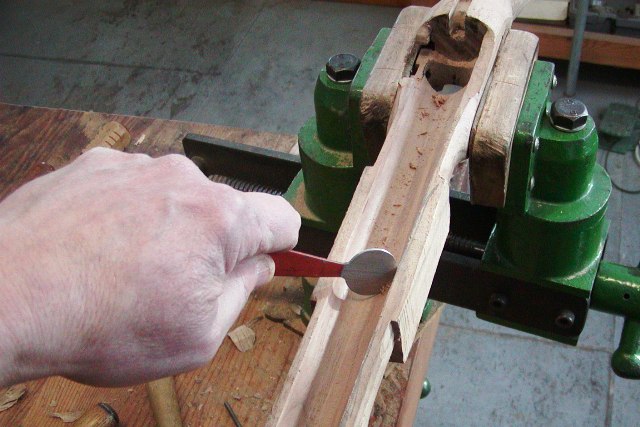

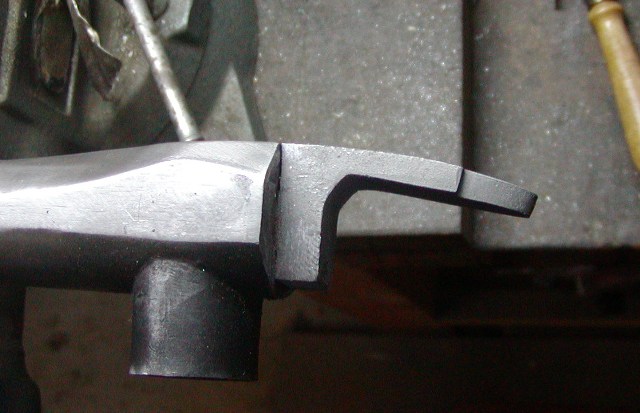

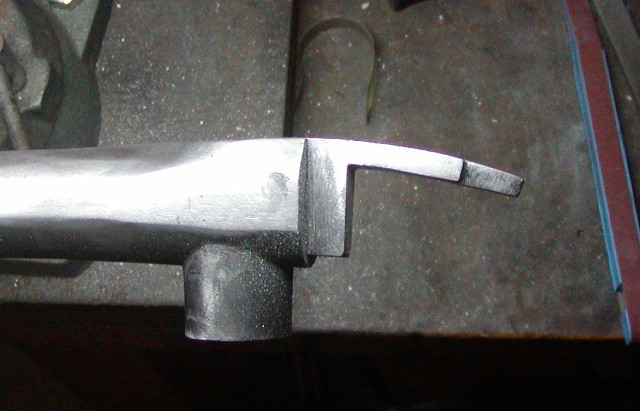

I am building this Ferguson rifle for a client down south. It is my third Ferguson but my first using the TRS precarved stock. I like Fergusons and shoot my personal rifle a lot. However, I have no illusions about the place of the Ferguson rifle in history. Patrick Ferguson and his rifle have almost a cult following. According to those folks if the British were not so stupid and made more Fergusons, we might have lost the Rev War. They also place Paddie on a pedestal as a far sighted visionary and superior officer. However, historical opinion and evidence is not so hegemonic. Ferguson did not invent the breech loading rifle design. He modified an existing design by Isaac de la Chaumette and made a few minor improvements. He was enough of an entrepreneur to stage demonstrations before the Ordnance and the king showing the advantages of his rifle. He was no fraud as a marksman and his demonstrations were legitimate and awe inspiring. But his rifle had some serious weaknesses as a military weapon. First, from the production standpoint, only a handful of British gun makers were qualified to make rifle barrel and breech. While those makers could produce 1,000 muzzleloading rifles, they struggled to make 100 Ferguson barrels and breeches and at 4 times the cost. Paddie put together his experimental rifle corps, who failed early marksmanship demonstrations but eventually congealed into a tight unit. That unit was thrust upon General William Howe in New York without his initial knowledge or consent. The rifle corps was a project of the king. General William Howe and his brother Admiral Richard Howe hated meddling in the American war by the government in Britain without it consulting them first. That put Ferguson and his experimental corps of riflemen on the wrong foot with Howe right away. They arrived in America and asked, "OK, here we are. What do you want us to do?" Anyway, they were put to use and Ferguson's riflemen acquitted themselves well but not superior to other groups like the German jaegers or John Simcoe' s Queens Rangers. They suffered heavy casualties during the Brandywine campaign and lost Ferguson owing to a serious wound. Ferguson recovered but his rifle corps was disbanded and the rifles ordered to be returned to stores in New York. That some of his rifleman kept their rifles is clear but to what extent remains a mystery. Ferguson was a good officer but neither Howe or Cornwallis trusted him. When he went south to operate under Cornwallis in South Carolina, Cornwallis did not trust him and was afraid he would impulsively get into trouble. He did at King's Mountain, a battle that should put to rest any illusion that Ferguson was a brilliant battlefield tactician or strategist.

dave

I am building this Ferguson rifle for a client down south. It is my third Ferguson but my first using the TRS precarved stock. I like Fergusons and shoot my personal rifle a lot. However, I have no illusions about the place of the Ferguson rifle in history. Patrick Ferguson and his rifle have almost a cult following. According to those folks if the British were not so stupid and made more Fergusons, we might have lost the Rev War. They also place Paddie on a pedestal as a far sighted visionary and superior officer. However, historical opinion and evidence is not so hegemonic. Ferguson did not invent the breech loading rifle design. He modified an existing design by Isaac de la Chaumette and made a few minor improvements. He was enough of an entrepreneur to stage demonstrations before the Ordnance and the king showing the advantages of his rifle. He was no fraud as a marksman and his demonstrations were legitimate and awe inspiring. But his rifle had some serious weaknesses as a military weapon. First, from the production standpoint, only a handful of British gun makers were qualified to make rifle barrel and breech. While those makers could produce 1,000 muzzleloading rifles, they struggled to make 100 Ferguson barrels and breeches and at 4 times the cost. Paddie put together his experimental rifle corps, who failed early marksmanship demonstrations but eventually congealed into a tight unit. That unit was thrust upon General William Howe in New York without his initial knowledge or consent. The rifle corps was a project of the king. General William Howe and his brother Admiral Richard Howe hated meddling in the American war by the government in Britain without it consulting them first. That put Ferguson and his experimental corps of riflemen on the wrong foot with Howe right away. They arrived in America and asked, "OK, here we are. What do you want us to do?" Anyway, they were put to use and Ferguson's riflemen acquitted themselves well but not superior to other groups like the German jaegers or John Simcoe' s Queens Rangers. They suffered heavy casualties during the Brandywine campaign and lost Ferguson owing to a serious wound. Ferguson recovered but his rifle corps was disbanded and the rifles ordered to be returned to stores in New York. That some of his rifleman kept their rifles is clear but to what extent remains a mystery. Ferguson was a good officer but neither Howe or Cornwallis trusted him. When he went south to operate under Cornwallis in South Carolina, Cornwallis did not trust him and was afraid he would impulsively get into trouble. He did at King's Mountain, a battle that should put to rest any illusion that Ferguson was a brilliant battlefield tactician or strategist.

dave