I would use the tung oil first, to fill the pores of the wood, then put on the design, and shellac over it. Shellac is a sealer. It has some pluses and minuses. It will yellow or darken in UV light. It is a sealer, but it can be " Cracked" with hard use, destroying its sealer quality. So, while it might work well on a paddle used in quiet waters( lakes, ponds) using it in fast water, where its likely to hit bottom, or rocks, or snags is going to be hard on that surface.

As with guns, there is no ONE answer to every use. Your paddle is a tool. I just finished reading the account of the rafting and river guide, and his choice of the longer paddle made of vinyl, and aluminum. I had to smile. His choice is obviously the best one for the work he is doing. It is not HC, or even PC, but it gets the tourists down stream alive and well. :grin: :thumbsup:

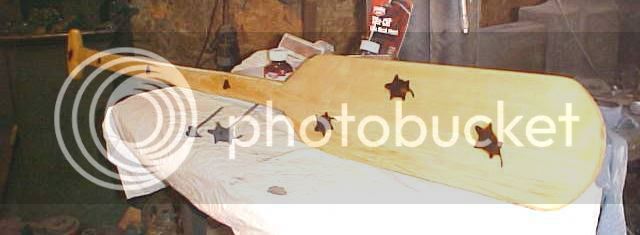

I particularly like the idea of a laminated bottom strip at right angles to the vertical grain of the rest of the paddle, to act as a bumper, and save the end grain from splitting out. In Theory, at least, if you destroy or badly damage the bumper plate, it can be replaced without buying a new paddle. That bumper strip is not historically correct for Native American built paddles. It is, as best I can learn, a late 20th century invention. But it works.

The same thing can be said about bent shaft, and bent handle paddles. There is a variety of handle angles being used, but they all increase the force and thrust applied on the water by the paddle for the energy used by the paddler. The only question is which angle is the best for whom? and for what kind of paddling. :hmm: