Maple stocks . Ordinary maple , curly maple , select curly maple , extra fine select curly maple . I've , as we all have , seen some absolutely beautiful curly maple stocks , but where do they come from ? Obviously maple trees but is there any indication from the exterior how fine the grain will be on the interior or is it just a matter of luck , cut enough maple and sooner or later you'll find beautiful grain . My street is about a half mile long , lined on both sides with maple trees . Yesterday we had a terrific storm with very high wind and about a dozen large maples came down . In the next few days the city workers will be around to saw the maples up and take them away . If i knew what to look for i'd get my chainsaw out and cut a few blanks . If i go to the trouble i want extra fine select stunning curly maple but how will i know it if i find it ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Curly Maple ?

- Thread starter atr

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Some wood grain patterns are made because of the way it is cut, fiddleback grain is this way, the chattering of the saw's teeth cause this stunning effect...

Hard maple has a fine, uniform texture, is resistant to abrasion...

It is heavy, strong, stiff, hard, and resistant to shock, and it has large shrinkage. Sugar maple is generally straight grained but the grain also occurs as "birds-eye," "curly," and "fiddleback" grain.

Hard maple has a fine, uniform texture, is resistant to abrasion...

It is heavy, strong, stiff, hard, and resistant to shock, and it has large shrinkage. Sugar maple is generally straight grained but the grain also occurs as "birds-eye," "curly," and "fiddleback" grain.

Wal, iffen it were someone besides Mooskeetman, I'd have to say "sorry to disagree..." but.... ::

From what I've learned over the years, no, you can't tell if the wood is curly by looking at the tree.

No one knows why one tree will have curl and another one right next to it won't.

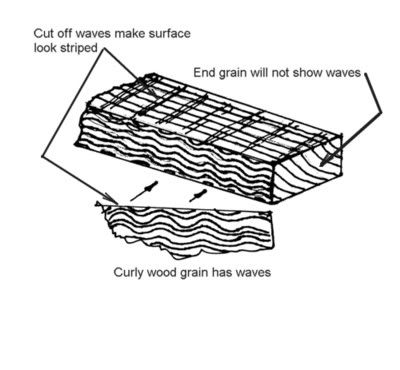

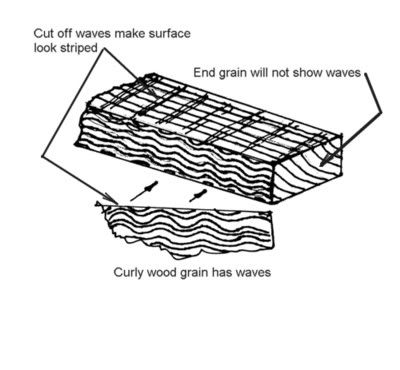

The thing that makes the wood have curl (or stripes when it is finished) is the wavyness of the woods grain.

If you want to test a piece, cut a limb which is at least 4 inches in diameter. You only need a 4 to 6 inch long piece.

Set it on end and split it. Then take each piece and split it again 90 degrees to the first split. Like all woods, the grain runs from one end of the piece to the other but most wood (includeing Maple) have a grain that just goes in a straight line from one end to the other.

If the grain is from a curly maple tree, the grain that it split along will be wavy, like this: ~~~~~~. (that's as good as my keyboard can do).

The waves are not real high, maybe 1/32 to 1/16 high.

The faster it waves back and forth the better it is because when it is finished, the stripes will look much closer together.

When you file, scrape or sand curly Maple, you are cutting the tops off of the wavy grain which exposes something that looks more like end grain. The remaining grain that is running parallel to the sanded surface looks like regular straight grain wood.

Hopefully a picture will show what I am talking about.

If the wood is cut diagnonally to the wavy grains (1/4 sawed) the wavyness will show best on all sides of the stock.

As for making a gunstock out of one of the trees, plan on letting it dry someplace like in the rafters of your house for at least 2 years.

From what I've learned over the years, no, you can't tell if the wood is curly by looking at the tree.

No one knows why one tree will have curl and another one right next to it won't.

The thing that makes the wood have curl (or stripes when it is finished) is the wavyness of the woods grain.

If you want to test a piece, cut a limb which is at least 4 inches in diameter. You only need a 4 to 6 inch long piece.

Set it on end and split it. Then take each piece and split it again 90 degrees to the first split. Like all woods, the grain runs from one end of the piece to the other but most wood (includeing Maple) have a grain that just goes in a straight line from one end to the other.

If the grain is from a curly maple tree, the grain that it split along will be wavy, like this: ~~~~~~. (that's as good as my keyboard can do).

The waves are not real high, maybe 1/32 to 1/16 high.

The faster it waves back and forth the better it is because when it is finished, the stripes will look much closer together.

When you file, scrape or sand curly Maple, you are cutting the tops off of the wavy grain which exposes something that looks more like end grain. The remaining grain that is running parallel to the sanded surface looks like regular straight grain wood.

Hopefully a picture will show what I am talking about.

If the wood is cut diagnonally to the wavy grains (1/4 sawed) the wavyness will show best on all sides of the stock.

As for making a gunstock out of one of the trees, plan on letting it dry someplace like in the rafters of your house for at least 2 years.

i saw a website that looks like the curl or burl of curly maple is taking from the base of the tree where it joins the roots....the blank on the millsaw was of the ball of roots at the base of the tree....i couldn't find the site for now....................................bob

Guest

Actualy you will also find curl in most all hardwood that been 1/4 sawn from the center of the round . ussally the first two cuts will have some kind of full curl getting less as you go out . In maple you will find spalted maple, figured maple, curly maple, birdseye maple, burled maple, wide spalted maple ...

The trick is to find consistence throught a piece . This is why premium curl costs so much . lets say you only get 2 good curl stock per round and out of say 50 rounds

The trick is to find consistence throught a piece . This is why premium curl costs so much . lets say you only get 2 good curl stock per round and out of say 50 rounds

Guest

here is a discription on how to 1/4 saw / http://www.woodweb.com/knowledge_base/Quarter_sawing.html

The following illustration shows two ways that logs are cut longitudinally (lengthwise) at the saw mill. Diagram "A" shows a log that is cut tangentially into boards. The tangential cut is also called slab-cut or plain-sawed lumber. Diagram "B" shows a log that is cut radially into boards. The radial cut is also called quarter-sawed lumber because the log is actually cut into quarters

This site has some good info on wood and the grains produced by different woods and why and is where I got the above diagram

wayns word

The following illustration shows two ways that logs are cut longitudinally (lengthwise) at the saw mill. Diagram "A" shows a log that is cut tangentially into boards. The tangential cut is also called slab-cut or plain-sawed lumber. Diagram "B" shows a log that is cut radially into boards. The radial cut is also called quarter-sawed lumber because the log is actually cut into quarters

This site has some good info on wood and the grains produced by different woods and why and is where I got the above diagram

wayns word

It's also got to do with the soil's mineral content and the nature of the soil (a tree that grows on a rocky crag will be different from one that grows on a river flat), the weather (tight growth rings in dry periods), Burks and branch crotches in the tree's overall morphology, prevalent wind (I've seen some trees that the internal grain was spiralled ). I do believe that same sugar maple tree that sap is drawn from can be the legendary "curly" maple once it falls to a lumberman.

Wood is (was) a living thing and it is dependent on the environment. A tree that's had an easy life has more tendencies to straight grain. Hardship builds character - just like in people.

Now here's a paradox. If we're so all fired concerned about accuracy, why aren't the more stable straight-grained stock blanks that are easier to cut true and retain their shape better in all weather worth more than the wild, irregular grained pieces? I guess accuracy really isn't the be all and end all.

Wood is (was) a living thing and it is dependent on the environment. A tree that's had an easy life has more tendencies to straight grain. Hardship builds character - just like in people.

Now here's a paradox. If we're so all fired concerned about accuracy, why aren't the more stable straight-grained stock blanks that are easier to cut true and retain their shape better in all weather worth more than the wild, irregular grained pieces? I guess accuracy really isn't the be all and end all.

A thought about wood and accuracy.

IMO, the modern gun enthusiast trys to relate sidelock full stock muzzleloaders with the guns he's most familure with.

By this I am refering to the mistaken notion that the stock has a lot to do with the guns accuracy.

While it is true that good bedding is important at the breech, it is IMO really only important when applied to the flimsy, skinny barrels we have on modern rifles.

When we are talking about a octagon barrel with a crossectional thickness of over 13/16 (more than often 15/16) and a flimsy piece of basically hollowed out Maple the effects are not hardly worth talking about.

Tomorrow when I have access to my computer (CATIA) at work I will build a 3D Solid model of a 42 inch long 15/16 octogan in .50 caliber and run an analysis on it by applying a 2 pound load (like a bent kentucky stock might create) to the end of it 90 degrees from the bore axis.

I suspect the deflection of the barrel from the load will be so small that it isn't worth worrying about.

I'll report my findings tomorrow.

IMO, the modern gun enthusiast trys to relate sidelock full stock muzzleloaders with the guns he's most familure with.

By this I am refering to the mistaken notion that the stock has a lot to do with the guns accuracy.

While it is true that good bedding is important at the breech, it is IMO really only important when applied to the flimsy, skinny barrels we have on modern rifles.

When we are talking about a octagon barrel with a crossectional thickness of over 13/16 (more than often 15/16) and a flimsy piece of basically hollowed out Maple the effects are not hardly worth talking about.

Tomorrow when I have access to my computer (CATIA) at work I will build a 3D Solid model of a 42 inch long 15/16 octogan in .50 caliber and run an analysis on it by applying a 2 pound load (like a bent kentucky stock might create) to the end of it 90 degrees from the bore axis.

I suspect the deflection of the barrel from the load will be so small that it isn't worth worrying about.

I'll report my findings tomorrow.

Tomorrow when I have access to my computer (CATIA) at work I will build a 3D Solid model of a 42 inch long 15/16 octogan in .50 caliber and run an analysis on it by applying a 2 pound load (like a bent kentucky stock might create) to the end of it 90 degrees from the bore axis.

I suspect the deflection of the barrel from the load will be so small that it isn't worth worrying about.

I'll report my findings tomorrow.

A HA! You've been holdin out on us! You is smart and literate! I Knewed it. When Claude said you was a CAD, I thought he was referren to that other kind.

No, Ah thin when Claude were talking about a CAD, he must ah been speaking of ma guns wit all of em inlays un comparing them with a Cadillac. :crackup: :crackup: :crackup: :crackup: :haha:

As I said I would do, I built a CATIA 3D Solid model of a octagon barrel. Actually I built two barrels and one stock forend.

My reason for making the forend is I really didn't know what a practical load would be. Analizing the forend using "timber" for a material may not be exactly right but it's most likely close to maple. The results of this model says a 1/2 pound load will bend it .47 inches (it is 42 inches long).

Anyway, based on this I figured .47 inches of warp is more than most guns will ever have so I used 1/2 pound for a load.

I built two 42 inch long barrels. One is a 7/8 octagon with a .50 caliber bore. The other is a 13/16 octagon with a .45 caliber bore.

Restraining the barrels .100 from the end and applying the load .100 from the other end, the 1/2 pound load bent the .45 cal 13/16 barrel .011. The 1/2 pound load bent the .50 cal 7/8 barrel .0065.

Trying to mimic the support of 10 inches of bedding at the breach I restrained 10 inches of barrel at one end and applied the 1/2 pound load to the other end.

Doing this, the .45 cal 13/16 barrel bent .0037, the .50 cal 7/8 barrel bent .0017.

To my way of thinking, although these results reflect what the bending would be, for it to really affect accuracy, the gun would have to be sighted in without a stock, and then mounted in the .47 warped stock to apply the load.

As no one would do this, and whatever force the stock forend applies to the barrel isn't going to change much while your shooting, I think I will stick to my thought that the effect of the stock on a heavy walled muzzleloading barrel is not significant.

I also learned that if I am sighted on the target, and a 1/2 pound bird lands on my barrel it is going to change the point of impact but most likely not from the birds weight. No, most likely it will be from shooing it off and then resighting on the departing bird while I touch it off.

::

My reason for making the forend is I really didn't know what a practical load would be. Analizing the forend using "timber" for a material may not be exactly right but it's most likely close to maple. The results of this model says a 1/2 pound load will bend it .47 inches (it is 42 inches long).

Anyway, based on this I figured .47 inches of warp is more than most guns will ever have so I used 1/2 pound for a load.

I built two 42 inch long barrels. One is a 7/8 octagon with a .50 caliber bore. The other is a 13/16 octagon with a .45 caliber bore.

Restraining the barrels .100 from the end and applying the load .100 from the other end, the 1/2 pound load bent the .45 cal 13/16 barrel .011. The 1/2 pound load bent the .50 cal 7/8 barrel .0065.

Trying to mimic the support of 10 inches of bedding at the breach I restrained 10 inches of barrel at one end and applied the 1/2 pound load to the other end.

Doing this, the .45 cal 13/16 barrel bent .0037, the .50 cal 7/8 barrel bent .0017.

To my way of thinking, although these results reflect what the bending would be, for it to really affect accuracy, the gun would have to be sighted in without a stock, and then mounted in the .47 warped stock to apply the load.

As no one would do this, and whatever force the stock forend applies to the barrel isn't going to change much while your shooting, I think I will stick to my thought that the effect of the stock on a heavy walled muzzleloading barrel is not significant.

I also learned that if I am sighted on the target, and a 1/2 pound bird lands on my barrel it is going to change the point of impact but most likely not from the birds weight. No, most likely it will be from shooing it off and then resighting on the departing bird while I touch it off.

::

What if you considered a lightweight swamped barrel with a large bore? (i.e. one with a thin walled waist) Lay one of those on your workbench and it doesn't seem to take much pressure to warp the barrel. Memory brings it back straight again when the pressure is off but a warped forrend could hold it in a permanent shallow curve. What does your computer model say about that situation? ( I'm mainly thinking of a 42" Colerain A weight in say 50 cal or something close to that. I've always been impressed at how easily they bend. Also it would seem a warpage of just a few thousandths of an inch would make a big difference at 100 yds.

I guess it's a relative call. As you alluded to earlier, I was weaned on bolt action bench shooting, where we'd use a torque wrench when tightening the action bolt (of course, the barrel was free floating) and fiberglass was replacing that "unstable" wood stuff in stock materials.

I was told that some barrel manufacturers actually bend the blanks in a jig so they can machine the "swamp" into a barrel with a straight cutting pass on a horizontal milling machine. That don't sound desireable.

Anyway, my original concern with the curly vs. straight is when the humidity and weather changes. Moisture enters wood from the end grains (at least that's where lumber mills glob the wax so it won't absorb moisture). When you inlet a barrel on a straight grained stock you defile fewer growth rings than when you cut the channel in a wavy, curly piece. I guess if we were getting 1/4" groups at 100 yards we'd notice the potential 1/2" drift due to weather changes a bit more?

Sorry, I 'll go back to sleep now.

I was told that some barrel manufacturers actually bend the blanks in a jig so they can machine the "swamp" into a barrel with a straight cutting pass on a horizontal milling machine. That don't sound desireable.

Anyway, my original concern with the curly vs. straight is when the humidity and weather changes. Moisture enters wood from the end grains (at least that's where lumber mills glob the wax so it won't absorb moisture). When you inlet a barrel on a straight grained stock you defile fewer growth rings than when you cut the channel in a wavy, curly piece. I guess if we were getting 1/4" groups at 100 yards we'd notice the potential 1/2" drift due to weather changes a bit more?

Sorry, I 'll go back to sleep now.

Similar threads

- Replies

- 0

- Views

- 451

- Replies

- 6

- Views

- 395