BigSkyRambler said:

The popsicle stick shim kind, sorta worked. For a minute. Did not have any suitable washers to try. The shim worked fine until I put any tightness on the lock plate screws. Gonna take some fiddling, but after watching the Packers get creamed, I have no enthusiasm for anything.

Two things to note here.

1. The triggers worked with the Popsicle stick shim.

2. The problems returned when you tightened the lock plate bolts.

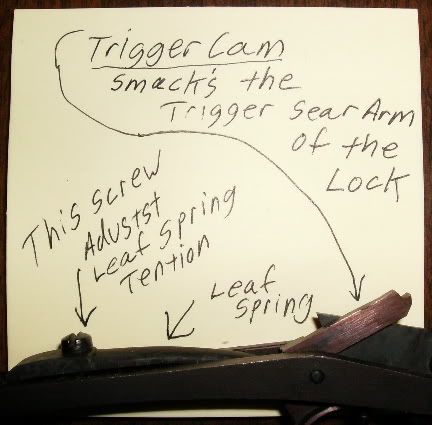

This is indicating that the lock is also being pulled too deep in the lock mortise and the sear is catching internally on the wood or the tumbler is catching and preventing the lock from functioning properly. You may need a shim in the lock mortise to provide some internal clearance. You also only need to tighten the bolts (trigger, lock and tang) to the snug. No need to over tighten.

If the trigger mortise was allowing the triggers to be pulled too far into the stock, then it is likely that the lock is also being pulled in too far also.

Look to see if the sear is rubbing in the recess in the lock mortise for the sear. Look for signs of rubbing anywhere in the lock mortise.