-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

danascus barrels

- Thread starter Flint50

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Damascus is used to label a certain metal product from a certain city called Damascus, and it is used to give a trade name of sorts to a metal working process.

Damascus process is nothing more then two different types of steel bars that are layered on each other and then hammer welded together many times to create a product that has the advantages of a harder steel with the advantages of a softer steel, much similar to japanese sword blades with the layered construction.

Damascus process is nothing more then two different types of steel bars that are layered on each other and then hammer welded together many times to create a product that has the advantages of a harder steel with the advantages of a softer steel, much similar to japanese sword blades with the layered construction.

Well that's a hoot! Learn somethin' everyday! I thought it was a remark that my dad always made when I did something stupid. I'd here him mutter "Dumb a**ed kid!" whenever I did something like back the car into the fence, or bring him the wrong this-or-that, or trip and fall....know what I mean?

Shucks! Now I know. Damascus...dumbasskid...damascus......see what I mean? Anybody else ever have theis problem or is it just me?

Shucks! Now I know. Damascus...dumbasskid...damascus......see what I mean? Anybody else ever have theis problem or is it just me?

Guest

I suppose there were some damascus barrels that were layered, I truly don't know. All I've ever read on the subject states that the two dissimilar metals, iron and steel as I understand it, were twisted together in 2, 3 or 4 ribbons. If I remember correctly it was called "roping". These "ropes" were then wrapped around a mandrel and hammer welded together to form the barrel. Upon completion of that process the barrel or barrels were trued up and I believe finish bored. If a double rifle or shotgun, which a lot of fine damascus was made in to, they were then silver soldered to the rib and in a rifle regulated to the load which had been chosen for whatever caliber it was. I've read little about shotguns but I would assume that some sort of regulation is necessary for them also.

I don't know if it was actually considered stronger than a conventionally welded barrel, I don't recall if I read somewhere that it was or was not. Someone else will hopefully have the answer to that. Common sense would tell one that the ribbons themselves are quite strong. Most concerns are with the quality of the weld which binds the ribbons where they join as they're twisted on the mandrel. Certainly there is no barrel or pair of barrels as beautiful as a fine, browned damascus barrel on a shotgun or rifle. Some of the four ribbon barrels are absolutely exquisite.

I did read an article once in Double Gun Journal where the writer(s) set out to blow up a damascus barrel and if I recall correctly it took something over the proof of the barrel to do so. This on a barrel that was approaching 100 years old. Seyfried certainly has no fear of fine British damacus once it's been gone over by a competent gun smith familiar with damascus. I suspect he is most often the gun smith referred to regarding checking the barrels.

I'm looking forward to reading other replies.

Vic

I don't know if it was actually considered stronger than a conventionally welded barrel, I don't recall if I read somewhere that it was or was not. Someone else will hopefully have the answer to that. Common sense would tell one that the ribbons themselves are quite strong. Most concerns are with the quality of the weld which binds the ribbons where they join as they're twisted on the mandrel. Certainly there is no barrel or pair of barrels as beautiful as a fine, browned damascus barrel on a shotgun or rifle. Some of the four ribbon barrels are absolutely exquisite.

I did read an article once in Double Gun Journal where the writer(s) set out to blow up a damascus barrel and if I recall correctly it took something over the proof of the barrel to do so. This on a barrel that was approaching 100 years old. Seyfried certainly has no fear of fine British damacus once it's been gone over by a competent gun smith familiar with damascus. I suspect he is most often the gun smith referred to regarding checking the barrels.

I'm looking forward to reading other replies.

Vic

Guest

Oh....I don't know when it was first used as a barrel material. I suspect the mid 1800's but that's as I said...merely my suspiscion. Could be that it goes back a lot longer than that.

Damascus went the way of the dodo bird with the advent of smokeless powder altho some were manufactured into the 1920's I believe, perhaps even a bit later.

Vic

Damascus went the way of the dodo bird with the advent of smokeless powder altho some were manufactured into the 1920's I believe, perhaps even a bit later.

Vic

robinghewitt

62 Cal.

- Joined

- Jun 26, 2004

- Messages

- 2,605

- Reaction score

- 22

Damascus gave it's name to two decorative metal styles.

Iron with inlayed precious metal.

Pattern weding as a decoration when iron and steel are combined then revealed.

As the barrels don't actually come from Damascus, you might call it "of Damascus" or "in the style of Damascus" as in damask or damascene. However damask usually refers to cloth specially woven so the pattern shows on both sides, so I prefer damascene.

The technique was used in England way back in Anglo Saxon times for making fancy swords, real works of art.

It was tough stuff that lasted right up to Henry Bessemer's converter (with a little help from Gilchrist-Thomas) :thumbsup:

Used for shotguns where a light barrel was desired you couldn't sell anything else once people started maked them in damascene. An early pioneer of steel shotgun barrels, Robert Adams of Adams revolvers fame, was nearly ruined when one of his early non-damascene efforts let go :shocking:

Iron with inlayed precious metal.

Pattern weding as a decoration when iron and steel are combined then revealed.

As the barrels don't actually come from Damascus, you might call it "of Damascus" or "in the style of Damascus" as in damask or damascene. However damask usually refers to cloth specially woven so the pattern shows on both sides, so I prefer damascene.

The technique was used in England way back in Anglo Saxon times for making fancy swords, real works of art.

It was tough stuff that lasted right up to Henry Bessemer's converter (with a little help from Gilchrist-Thomas) :thumbsup:

Used for shotguns where a light barrel was desired you couldn't sell anything else once people started maked them in damascene. An early pioneer of steel shotgun barrels, Robert Adams of Adams revolvers fame, was nearly ruined when one of his early non-damascene efforts let go :shocking:

Guest

here is a link to a past topic we had , may find some intrest there .also i have posted a few types of paternhttp://www.muzzleloadingforum.com/ubbthr...=true#Post73868

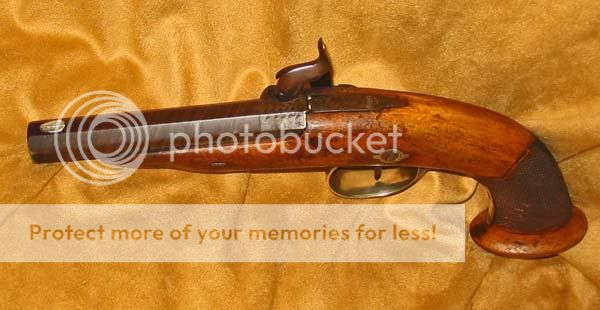

As some of you may know, I posted about this pistol I bought last week on the Precussion Forum. It's called New/Old Pistol.

Anyway, I think this is a Demascus barrel Pistol. It has Belgian Proof marks on it.

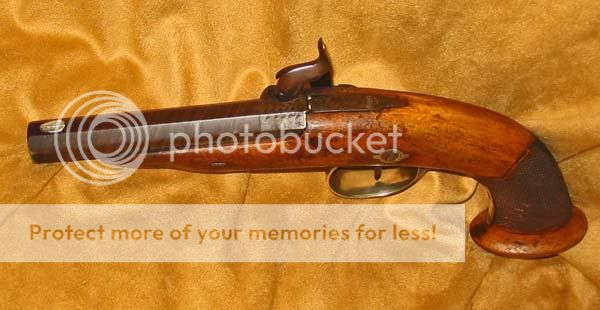

Below is the underside of the barrel:

Below is the underside of the barrel:

I just added to the post in the Precussion Forum asking about a flaw I found in the bore. I would appreciate it if any of you folks knowing about this type of barrel would follow this link and give me your thoughts:

Pistol Post

Anyway, I think this is a Demascus barrel Pistol. It has Belgian Proof marks on it.

I just added to the post in the Precussion Forum asking about a flaw I found in the bore. I would appreciate it if any of you folks knowing about this type of barrel would follow this link and give me your thoughts:

Pistol Post

Guest

Zonie, that's one fine looking pistol.What about putting a new barrel and patent breech on it, so as not to worry about the pit in the barrel. If you really want to shoot her, I would proof it with say 60 grains of FFF, with a single patched ball. Proof the barrel only, seperate from the stock. I would then work up a light load, say maybe 35-40 grains. I don't think you would have that high of pressure, with a light load like that. Just my thoughts on it. Another choice might be to duplicate it, there's plenty of old shotgun backaction locks around. I could see you getting a right, and left hand lock and making a matched pair. He He Bill :m2c: Oh Yeah, I like the front sight addition

Guest

Zonie....I can't tell if it's damascus (for others reading this post, yes, I know, most particularly called pattern welded but we'll simplify things ). Judging from the serial number on the bottm of the barrel I assume this is not a real old gun. If it is I stand corrected and offer my apology for my ignorance.

Easiest way to tell is to find out if the pattern is on the barrel or in the barrel. A very slight file cut on the bottom side would tell you immediately. Something you may not want to do if the pistol is an antique. Some makers in the US back in the early part of the 20th century and perhaps latter 19th century would apply (etch?) a damascus pattern on fluid steel barrels. These are easy to tell beceause somewhere on the barrel the pattern is worn off. I have no clue what may have occurred in Belgium. When you find out I'd be curious to know. I've never seen a damascus patter such as the one exhibited on your pistol.

Vic

Easiest way to tell is to find out if the pattern is on the barrel or in the barrel. A very slight file cut on the bottom side would tell you immediately. Something you may not want to do if the pistol is an antique. Some makers in the US back in the early part of the 20th century and perhaps latter 19th century would apply (etch?) a damascus pattern on fluid steel barrels. These are easy to tell beceause somewhere on the barrel the pattern is worn off. I have no clue what may have occurred in Belgium. When you find out I'd be curious to know. I've never seen a damascus patter such as the one exhibited on your pistol.

Vic

Guest

Actually Damascus barrels can lose there pattern over time

and contrary to some they can be blued .

Sharps ,,,,,is correct later on some companies etched a print to their barrels

and filing will remove this, as does age , just as with true pattern steal or what

we are calling Damascus, Which sometimes is not Damascus but laminated steal .

i would tend to lean to this being a damascus barrel as i have never seen prented damascus in this patern , normaly that was done in the heavy patterns .

however

The easiest way to tell if the pattern is in the barrel is to lightly draw file it

and contrary to some they can be blued .

Sharps ,,,,,is correct later on some companies etched a print to their barrels

and filing will remove this, as does age , just as with true pattern steal or what

we are calling Damascus, Which sometimes is not Damascus but laminated steal .

i would tend to lean to this being a damascus barrel as i have never seen prented damascus in this patern , normaly that was done in the heavy patterns .

however

The easiest way to tell if the pattern is in the barrel is to lightly draw file it

Thanks everyone.

As a follow up on the pistol barrel. I filed about 3/8 of an inch of the flat behind the underlug down to remove all traces of the pattern. I then sanded it down using 320, then 600 grit wet/dry paper. This area was then polished using my Dremal, a small felt disk and Stainless polishing compound.

All traces of any pattern were removed, leaving a smooth mirror surface.

I then degreased the area using lacquer thinner, then acetone.

The place I work at has a group of Metallurgical Engineers.

They took a instant intrest in the thought that I might have a demascus barrel, and provided a little nitric acid etching solution. (3% nitric acid & 97% alcohol)

After applying the solution several times, I dipped a hair paintbrush into it and let the brush rest on the surface for about a minute. This discolored the surface and removed all traces of the polishing.

The best part, is the discoloration was striped with the same pattern, just like the surface was before I filed it.

After this test, I am convinced that this barrel is demascus steel.

Someone noted the barrel was serialized.

I believe the serial number only says the gun was made at a factory for commercial sale. The same number is stamped on the breech block, and someone wrote it in the stocks barrel channel with what looks like India Ink. The stock finish was put on over this marking.

As a follow up on the pistol barrel. I filed about 3/8 of an inch of the flat behind the underlug down to remove all traces of the pattern. I then sanded it down using 320, then 600 grit wet/dry paper. This area was then polished using my Dremal, a small felt disk and Stainless polishing compound.

All traces of any pattern were removed, leaving a smooth mirror surface.

I then degreased the area using lacquer thinner, then acetone.

The place I work at has a group of Metallurgical Engineers.

They took a instant intrest in the thought that I might have a demascus barrel, and provided a little nitric acid etching solution. (3% nitric acid & 97% alcohol)

After applying the solution several times, I dipped a hair paintbrush into it and let the brush rest on the surface for about a minute. This discolored the surface and removed all traces of the polishing.

The best part, is the discoloration was striped with the same pattern, just like the surface was before I filed it.

After this test, I am convinced that this barrel is demascus steel.

Someone noted the barrel was serialized.

I believe the serial number only says the gun was made at a factory for commercial sale. The same number is stamped on the breech block, and someone wrote it in the stocks barrel channel with what looks like India Ink. The stock finish was put on over this marking.

Guest

Well Zonie, I'd say ya got a "real McCoy"!! The pattern is obviously in the barrel and not on it!

I did not know real damascus would fade over time with use. Been an interesting and educational post.

Vic

I did not know real damascus would fade over time with use. Been an interesting and educational post.

Vic

Similar threads

- Replies

- 2

- Views

- 515

- Locked

- Replies

- 5

- Views

- 775