Charcoal blueing can look like that but is usually done to barrels. Heat a trough of charcoal with the barrel buried in the coals.

Tempering or fire blue wears quickly in my experience. Heating red hot and quenching in potassium nitrate gives color like that too.

Concerning our periods of study, the 18th and 19th Centuries....

To simplify the “ heat” bluing processes for barrels it come down to two basic processes.

1. Charcoal Blue....

The item like a barrel is buried in charcoal. Usually it’s in an iron trough with a log fire under the trough. The trough of charcoal burns in in a slow manner. The barrel is buried in the trough of coals.

Every few minutes the barrel is removed and replaced primarily to keep the color even.

There’s various methods for this process.

Sometimes the bore is packed with charcoal.

Sometimes not.

Sometimes the barrel is retrieved and wiped down with lime laden rags...

Sometimes not.

Sometimes the elevated trough is used.

Sometimes the barrel is simply buried in a trench of coals.

There’s different methods of this basic process.

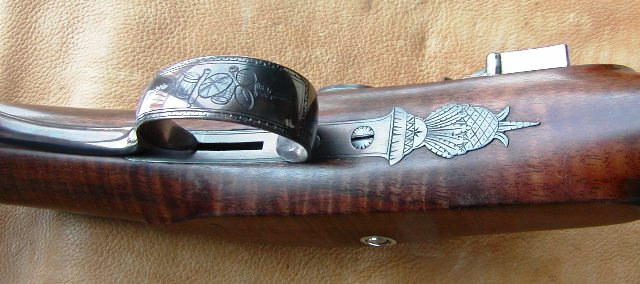

True Charcoal blue produces a deep blackish blue that will usually show a slight mottled appearance due to uneven heating from the individual coals.

It’s a very attractive finish.

Also it’s my understanding that a “skin” is sometimes produced that can flake off over time...a long period of time.

I believe that is one reason the bore was packed with charcoal, to prevent scale from forming inside the bore.

This can be a pretty tough finish.

Heat blue....

Heat blue is very similar to charcoal blue. Instead of the barrel being buried in coals, it is suspended above the heat source.

This method produces an vibrant almost electric looking blue.

It’s a very beautiful color but it is rather delicate. The part will turn back to the white/gray or “brown” over time.

Wallace Gussler believes that a large number of 18th Century American Longrifle barrels were blued this way.

This is based on traces of this vibrant blue being seen on the underside of the barrels when these old guns were disassembled.

These two historic process can become rather confusing even for the best firearm historian.

Both processes use coals or charcoal.

Even a barrel that’s buried in coals may end up being a heat blue rather than a true charcoal blue because it was not allowed “soak” long enough to form that dark charcoal blue.

When you add in factory marketing like Colt or Winchester and even Mauser it’s gets even more confusing.

Then you have present day marketing, for instance “ charcoal blues” revolvers from .... for instance Cimarron firearms.

Those vibrant blues are more akin to the electric heat blue rather than the charcoal soak.

It’s quite a study.