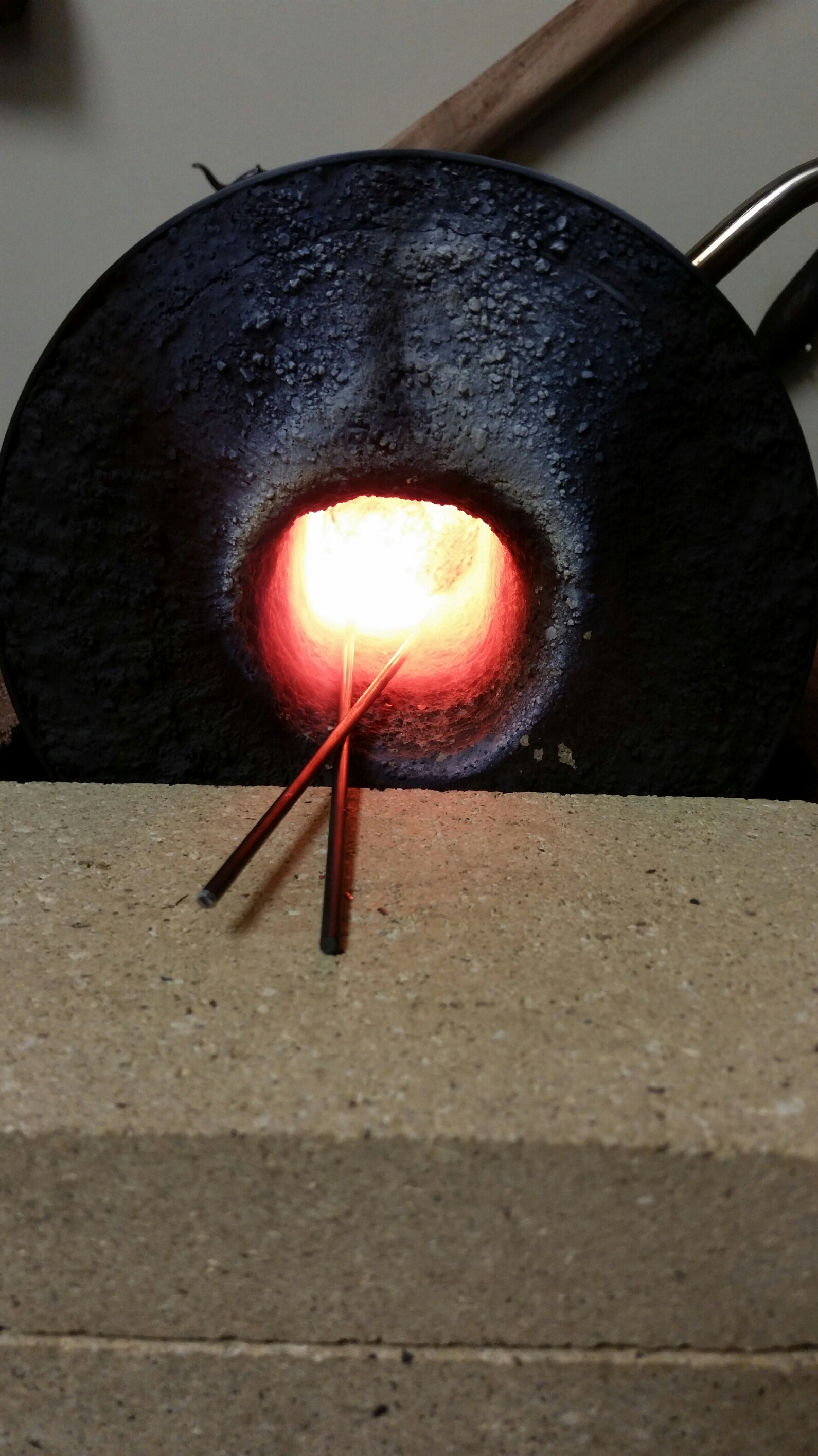

I was about to make a quick and dirty propane powered forge. I've got a piece of railroad track for an anvil. But TSC has anthracite coal on sale for $4.50 a bag (40#). Feel free to talk me into a coal forge if they are easy to make.

I made one of those twisted forks last Saturday using only a torch. I needed a bit more heat.

I made one of those twisted forks last Saturday using only a torch. I needed a bit more heat.