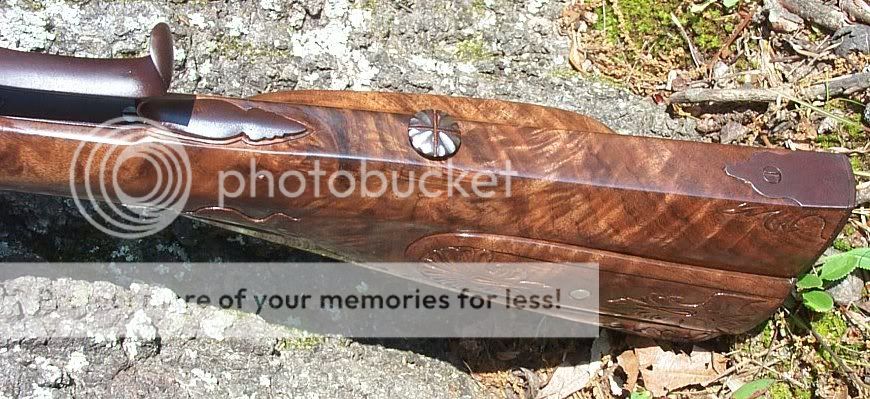

I am toying with the notion of putting a sling swivel on my full stock Renegade.

The question I have is, do I NEED to install another "tab" in the barrel to put the screw through? Would it be OK to just drill through over the rod thimble and call it good, or even install one of those brass tubes(similar to the ones used for some knife lanyard holes) through the stock over the thimble? I would imagine that would be strong enough to take the pressure from a sling, but I would like to have input from those more experienced. Thanks.

The question I have is, do I NEED to install another "tab" in the barrel to put the screw through? Would it be OK to just drill through over the rod thimble and call it good, or even install one of those brass tubes(similar to the ones used for some knife lanyard holes) through the stock over the thimble? I would imagine that would be strong enough to take the pressure from a sling, but I would like to have input from those more experienced. Thanks.