We had some Nitric Acid sitting idle at the Lab where I work, so I mixed up a 10% Solution and tried it on a scrap piece of curly maple. Put it on and heated it up with a heat gun until it blushed red. Really brought out the shimmer!

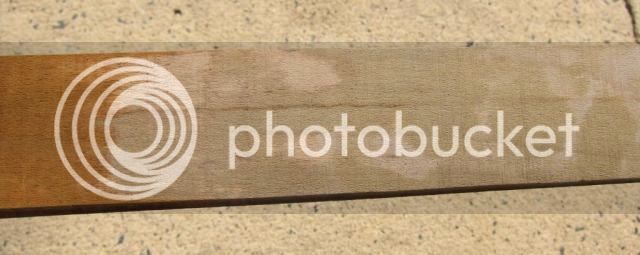

However, when I neutralized the acid by scrubbing the board with a baking soda solution and then rinsing with water, I noticed the baking soda had given the board a greenish cast. You can really see it in this photo where the baking soda got on some of the untreated wood.

In addition to the greenish cast, the baking soda seemed to reduce the shimmer (chatoancy?) some too.

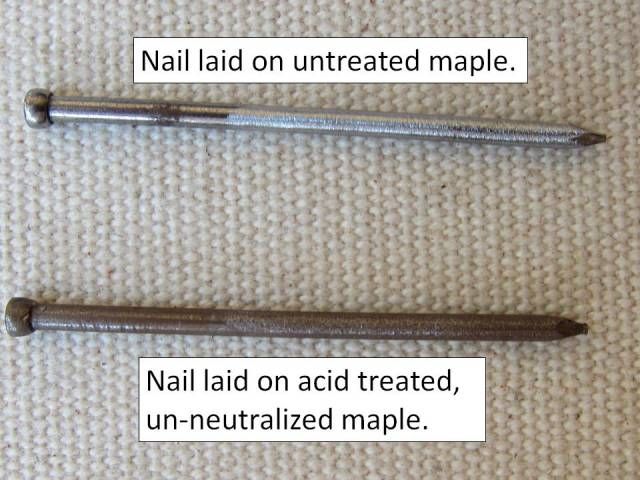

I was bummed out about all that, so I got to thinking that maybe neutralizing the acid wasn't necessary, since I'm heating and basically boiling it all away with the heat gun. So I did an experiment: I sanded two nails to expose fresh steel, and laid one nail on untreated maple and the other on nitric acid treated but un-neutralized maple. I left them in my hot but dry garage for a week. After a week the nail on the untreated board was still shiny, but the nail on the acid-treated board was rusty. So my theory was wrong. :td:

Anyone else seen this? I'm wondering if I add a couple drops of red stain to the finish if I can kill the green? Also wondering if the nail would still rust if I didn't neutralize the acid but put the finish on it to seal it?

However, when I neutralized the acid by scrubbing the board with a baking soda solution and then rinsing with water, I noticed the baking soda had given the board a greenish cast. You can really see it in this photo where the baking soda got on some of the untreated wood.

In addition to the greenish cast, the baking soda seemed to reduce the shimmer (chatoancy?) some too.

I was bummed out about all that, so I got to thinking that maybe neutralizing the acid wasn't necessary, since I'm heating and basically boiling it all away with the heat gun. So I did an experiment: I sanded two nails to expose fresh steel, and laid one nail on untreated maple and the other on nitric acid treated but un-neutralized maple. I left them in my hot but dry garage for a week. After a week the nail on the untreated board was still shiny, but the nail on the acid-treated board was rusty. So my theory was wrong. :td:

Anyone else seen this? I'm wondering if I add a couple drops of red stain to the finish if I can kill the green? Also wondering if the nail would still rust if I didn't neutralize the acid but put the finish on it to seal it?