I got some drop in bore lights (aka: bobber lights). I have a Pedersoli Kentucky flinter in .50 cal. I pulled the lock and vent liner off and when I looked into the now illuminated breach area, I noticed no rifling. For kicks I ran a patch down the bore and it bottomed out before it came into sight. So, I have to conclude that not only is the breach area not rifled because it need not be, also the breech area is narrower than the rest of the bore. It also seems that the breech plug had a convex indentation to it as well. I've seen videos of how modern firearms are made but I don't know as much as I would like about ML guns. Can anyone share why these items are built into the rifle?

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Had not noticed this before....

- Thread starter Flintlock Whiskey

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

TDM

Cannon

- Joined

- May 28, 2022

- Messages

- 9,656

- Reaction score

- 24,208

- Location

- Louisiana & My camp in Mississippi

Interesting, I’ve not seen or noticed that before. But I’ve never really looked that close I guess.

You beat me to it by seconds. Haha.

TDM

Cannon

- Joined

- May 28, 2022

- Messages

- 9,656

- Reaction score

- 24,208

- Location

- Louisiana & My camp in Mississippi

Didn’t even think about the description being a patent breech. But agree. Also agree that I do not like them, unfortunately I have a couple.

THEY ARE NO HARDER TO CLEAN THEN ANY OTHER BREECH ! IF YOU REMOVE YOUR BARREL PUT THE BREECH IN A BUCKET AND PUMP FOR A MINUTE OR TWO WITH A THICH PATCH ON YOUR JAG, I FLUSH MINE UNTIL THE BARREL GETS UNCOMFORTABLE TO HOLD WITH HOT WATER NO SOAP OR CLEANING PRODUCTS REQUIRED ( NON OF THE ERA/PERIOD CORRECT EVER HAD SOAP IN THEIR POSSIBLES POUCH TO CLEAN WITH) IT TAKES LONGER TOBOIL THE WATER THEN IT DOES TO TAKE THE BARREL OFF AND FLUSH IT AND YES I REMOVE MY PINNED BARRELS EVERY TIME AND IN 20 YEARS THEY ARE STILL AS TIGHT AS THE DAY THEY WE'RE MADE ! THE CLAMP THAT TRACK SELLS WORKS BUT AGAIN IT WAS NEVER FOUND IN A LONG HUNTER OR TRAPPER'S KIT. I HAVEN'T TRIED THE MAGNETIC ONE, IF IT WORKS WOULD MAKE FITTING TO THE GUN ALOT EASIER. IF YOU DON'T WANT TO REMOVE THE BARREL JUST PLUG THE NIPPLE/VENT FILL WITH BOILING WATER AND LET SIT FOR A MINUTE OR SO REMOVE THE PLUG AND PUSH IT OUT THROUGH THE NIPPLE/VENT WITH THE GUN TILTED SO THE WATER DOESN'T RUN DOWN THE STOCK 5-6 PATCHES AND IT WILL BE DRY RUN A LUBED PATCH DOWN AND OUT TURN IT OVER AND REPETE YOUR GUN IS NOW CLEAN. IT HAS TAKEN ME LONGER TO TYPE THIS THEN IT TAKES TO DO IT EVEN AFTER SHOOTING ALL DAY AT A TERRITORIAL.

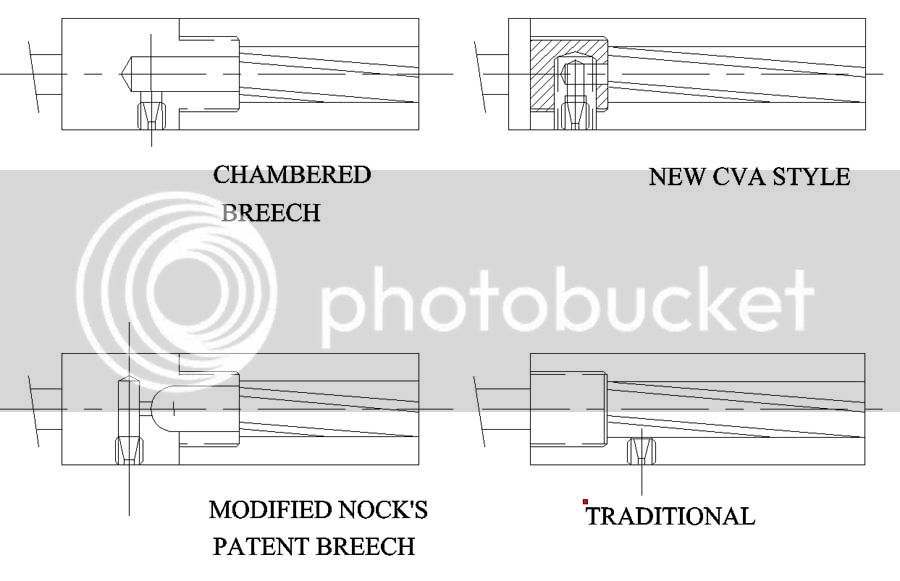

As can be seen in @kyron4's post, what you are seeing is a chambered breech. there is no need for rifling as the ball can't get into the chambered breech. The real benefit of a chambered breech is in the manufacturing process. Only one type of barrel needs to be inventoried. All the barrels can be threaded for the threads of the chambered breech. An unintended consequence is that there is more material at the breech to contain the pressure of ignition. The manufacturer can have four types of chambered breeches in inventory. Flint breeches, percussion breeches, and right and left breeches. With a bit of planning, a touch hole liner and a flint drum can have the same threading and only two breeches need to be in inventory.I got some drop in bore lights (aka: bobber lights). I have a Pedersoli Kentucky flinter in .50 cal. I pulled the lock and vent liner off and when I looked into the now illuminated breach area, I noticed no rifling. For kicks I ran a patch down the bore and it bottomed out before it came into sight. So, I have to conclude that not only is the breach area not rifled because it need not be, also the breech area is narrower than the rest of the bore. It also seems that the breech plug had a convex indentation to it as well. I've seen videos of how modern firearms are made but I don't know as much as I would like about ML guns. Can anyone share why these items are built into the rifle?

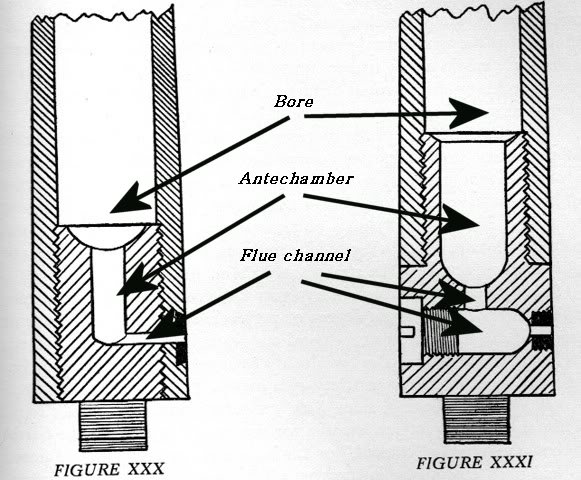

Patent breeches are a far more complicated design. Actually, only Nock's design can be truly called a patent breech. The theory is that the powder in the antechamber by the touch hole ignites and sends a strong jet of flame into the powder charge. In some of Nock's designs, there is a tiny relief hole with the theory that the relief hole provides a pathway for the heat from the pan ignition to flow through the powder charge in the antechamber for faster and improved ignition. In practice, it does work with the strong jet of burning powder keeping the chamber and antechamber mostly clear of fouling. No current factory production utilizes a Patent Breech system as designed by Nock.

Of course they didn’t carry soap in their possibles bags, but that doesn’t mean they didn’t have it in camp. Our ancestors were far more hygienic than modern people think.THEY ARE NO HARDER TO CLEAN THEN ANY OTHER BREECH ! IF YOU REMOVE YOUR BARREL PUT THE BREECH IN A BUCKET AND PUMP FOR A MINUTE OR TWO WITH A THICH PATCH ON YOUR JAG, I FLUSH MINE UNTIL THE BARREL GETS UNCOMFORTABLE TO HOLD WITH HOT WATER NO SOAP OR CLEANING PRODUCTS REQUIRED ( NON OF THE ERA/PERIOD CORRECT EVER HAD SOAP IN THEIR POSSIBLES POUCH TO CLEAN WITH) IT TAKES LONGER TOBOIL THE WATER THEN IT DOES TO TAKE THE BARREL OFF AND FLUSH IT AND YES I REMOVE MY PINNED BARRELS EVERY TIME AND IN 20 YEARS THEY ARE STILL AS TIGHT AS THE DAY THEY WE'RE MADE ! THE CLAMP THAT TRACK SELLS WORKS BUT AGAIN IT WAS NEVER FOUND IN A LONG HUNTER OR TRAPPER'S KIT. I HAVEN'T TRIED THE MAGNETIC ONE, IF IT WORKS WOULD MAKE FITTING TO THE GUN ALOT EASIER. IF YOU DON'T WANT TO REMOVE THE BARREL JUST PLUG THE NIPPLE/VENT FILL WITH BOILING WATER AND LET SIT FOR A MINUTE OR SO REMOVE THE PLUG AND PUSH IT OUT THROUGH THE NIPPLE/VENT WITH THE GUN TILTED SO THE WATER DOESN'T RUN DOWN THE STOCK 5-6 PATCHES AND IT WILL BE DRY RUN A LUBED PATCH DOWN AND OUT TURN IT OVER AND REPETE YOUR GUN IS NOW CLEAN. IT HAS TAKEN ME LONGER TO TYPE THIS THEN IT TAKES TO DO IT EVEN AFTER SHOOTING ALL DAY AT A TERRITORIAL.

That said, all I ever use is straight up boiling water- the best documented and most hassle-free historic method.

Jay

X2.Adds strength to the side wall area of breach, (thicker) , and reportedly gives more even ignition. Pain to clean, most, myself included, don't like them.

With the chambered breech, there is a cavity that you can fill with powder in the unlikely event that you have forgotten the prime instruction and didn't load powder before you loaded the ball.

hanshi

Cannon

I only have one rifle with a "patent breech" and it's a favorite of mine. All others have a flat breech which I prefer. I never had any kind of problem cleaning rifles with a PB. I don't like them but admittedly have had ZERO problems with them.

Both mine have it. No problems cleaning it.

bronko220002

45 Cal.

I didn't read all the post but I'd have to say the reason the breech isn't rifled is because it doesn't need to be. Your ball won't be down that far. Secondly the breech is slightly narrower so the rifling cutting tool cannot get to that area. No need to worry. Your rifle is perfectly fine.

- Joined

- Feb 20, 2013

- Messages

- 665

- Reaction score

- 937

I beg to disagree- while not HC the most hassle free method is hose water.Of course they didn’t carry soap in their possibles bags, but that doesn’t mean they didn’t have it in camp. Our ancestors were far more hygienic than modern people think.

That said, all I ever use is straight up boiling water- the best documented and most hassle-free historic method.

Jay

I used to boil water but got flash rust instantly. Went to warm soapy water, had to rinse with plain cold water anyway…

My routine has evolved (or Devolved) into just plain water: no heat, no soap.

You can always coat the bore with shortening and bake it in the oven to season it.....just kidding...

I will give it a try.Of course they didn’t carry soap in their possibles bags, but that doesn’t mean they didn’t have it in camp. Our ancestors were far more hygienic than modern people think.

That said, all I ever use is straight up boiling water- the best documented and most hassle-free historic method.

Jay

Thanks.As can be seen in @kyron4's post, what you are seeing is a chambered breech. there is no need for rifling as the ball can't get into the chambered breech. The real benefit of a chambered breech is in the manufacturing process. Only one type of barrel needs to be inventoried. All the barrels can be threaded for the threads of the chambered breech. An unintended consequence is that there is more material at the breech to contain the pressure of ignition. The manufacturer can have four types of chambered breeches in inventory. Flint breeches, percussion breeches, and right and left breeches. With a bit of planning, a touch hole liner and a flint drum can have the same threading and only two breeches need to be in inventory.

Patent breeches are a far more complicated design. Actually, only Nock's design can be truly called a patent breech. The theory is that the powder in the antechamber by the touch hole ignites and sends a strong jet of flame into the powder charge. In some of Nock's designs, there is a tiny relief hole with the theory that the relief hole provides a pathway for the heat from the pan ignition to flow through the powder charge in the antechamber for faster and improved ignition. In practice, it does work with the strong jet of burning powder keeping the chamber and antechamber mostly clear of fouling. No current factory production utilizes a Patent Breech system as designed by Nock.

That’s why I specified “historic method.” Though I’m sure if they’d’a had a garden hose, they’d’a used it.I beg to disagree- while not HC the most hassle free method is hose water.

I used to boil water but got flash rust instantly. Went to warm soapy water, had to rinse with plain cold water anyway…

My routine has evolved (or Devolved) into just plain water: no heat, no soap.

Jay

Similar threads

- Replies

- 4

- Views

- 638