Ole Frog

40 Cal.

- Joined

- Mar 25, 2013

- Messages

- 156

- Reaction score

- 10

I need some help to figure out where I am going with a bag I want to make

I have made simple bags and I use 3-4 oz leather

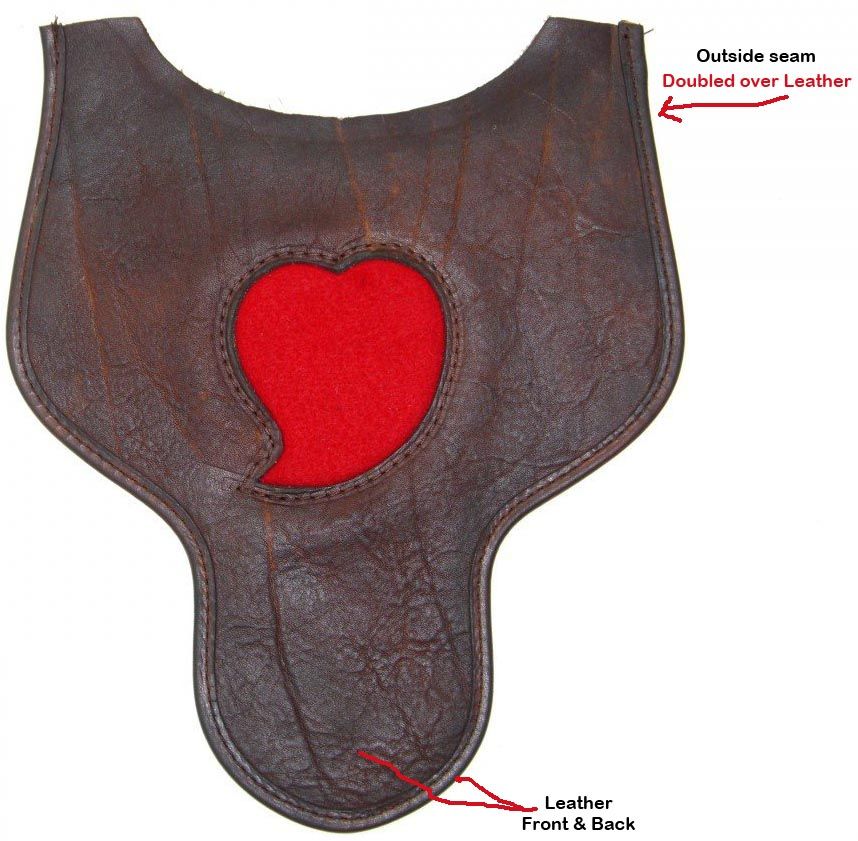

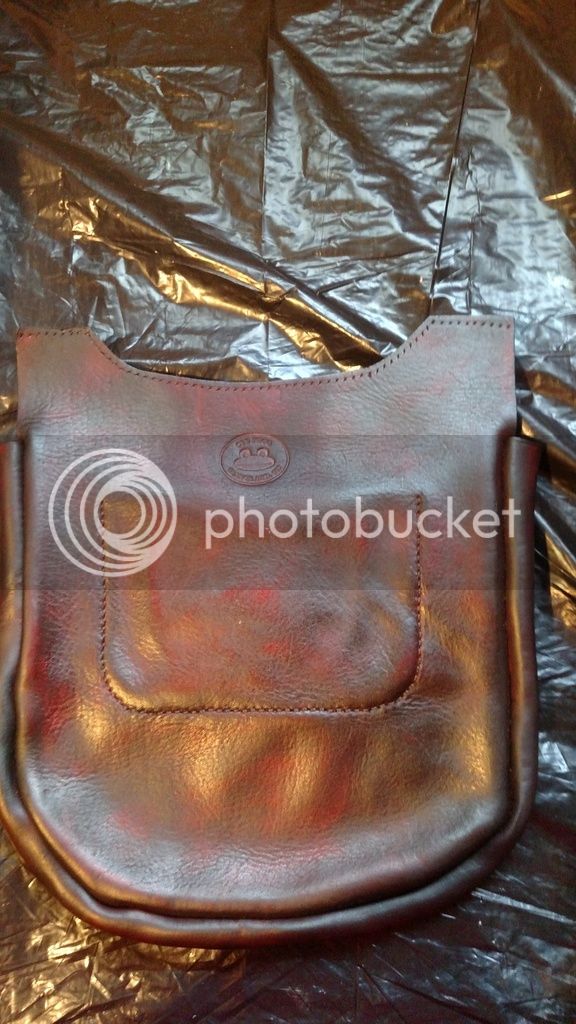

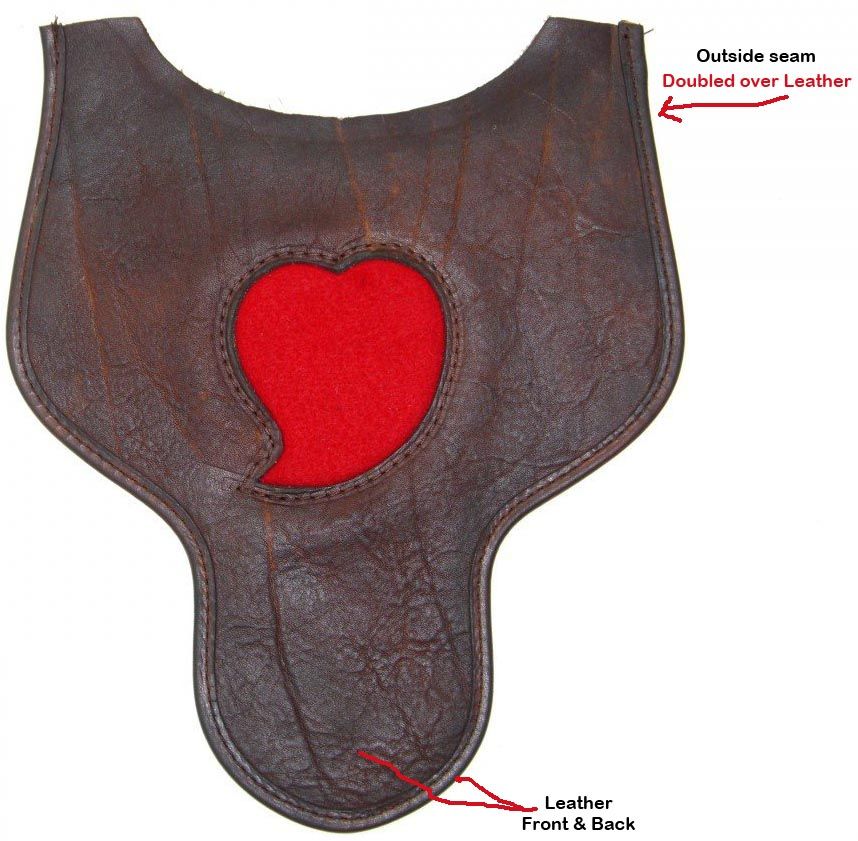

I would like to make a bag with the red heart in the front of it. The book "Recreating the 18th Century Hunting Pouch" uses leather front & back

1.) If I use leather front and back of the heart, that will be 6-8 oz of leather

Wont that be too thick?

2.) What do you guys use when you add an outside seam around the flap?

isn't 3-4 oz too thick to double over?

How do you guys do it?

John

I have made simple bags and I use 3-4 oz leather

I would like to make a bag with the red heart in the front of it. The book "Recreating the 18th Century Hunting Pouch" uses leather front & back

1.) If I use leather front and back of the heart, that will be 6-8 oz of leather

Wont that be too thick?

2.) What do you guys use when you add an outside seam around the flap?

isn't 3-4 oz too thick to double over?

How do you guys do it?

John