(I apparently was typing this at the same time that EC121 was writing his reply, but he beat me. We basically are saying the same thing.)

Not that I know of.

The rule of thumb for barrel thickness at the breech or powder chamber is about 0.2". A 15/16" barrel in .54 caliber has a wall thickness of (0.9375 - 0.54) / 2 = 0.199". A 1" barrel in .58 caliber has a wall thickness of (1.0 - 0.58) / 2 = 0.21". A 1-1/16" barrel in .62 caliber has a wall thickness of (1.0625 - 0.62) / 2 = 0.22".

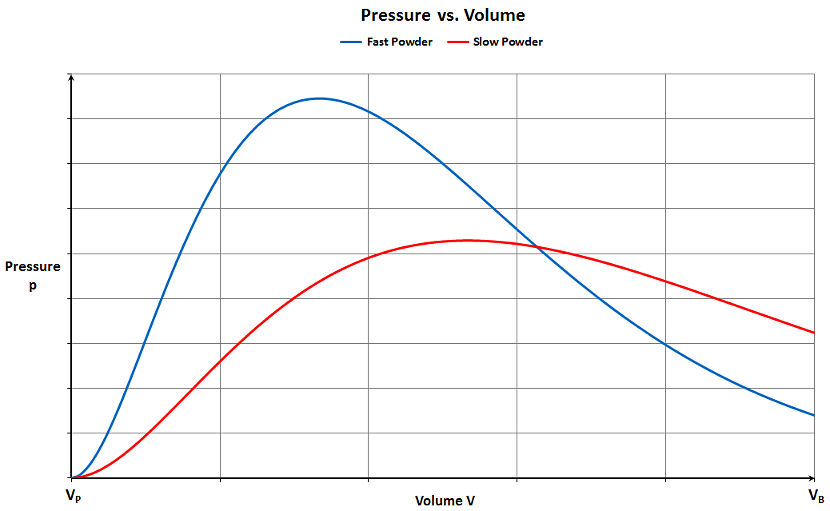

But the barrel doesn't need to be that thick further down because the pressure in the bore falls off as the ball travels down the bore. That's why swamped barrels and tapered barrels are practical.

The pressure curve depends on a lot of variables such as powder type and granulation, powder volume, projectile, caliber, bore roughness, etc. Too many variables to make a meaningful chart.

Another way of looking at this is just how deep does one need to cut a dovetail to hold whatever is placed in the dovetail?

For some reason you wanted to exclude underlugs in this discussion, so you must be asking about dovetails for sights. What does it take to hold a sight on a barrel? Not much. Most rear sights for muzzleloaders come with dovetails that are much deeper than needed. If you are placing a sight on a barrel where the wall may be approaching 0.1" thick, make the dovetail less than 0.050" deep.

Even though you didn't want to talk about them, the same applies to underlugs for barrel pins and keys. The underlugs don't have a lot of force exerted on them. The breech and tang/tang bolt are absorbing most of the recoil. They pretty much only need to be strong enough to hold the forestock on the barrel. The master gunmaker that I'm taking lessons from has instructed me that standard dovetails of 0.060-0.050" deep are all that is needed and can be as shallow as 0.030" in the waist of a swamped barrel.

A common problem of deep dovetails in thin wall sections is that the process of cutting the dovetail and installing the lug or whatever can sometimes dent or push in the thin wall under the dovetail making a restriction in the barrel or tight spot in the barrel.

There is a thread on this forum where a guy had a jag stuck in the bore of a large caliber smoothbore a few inches into the bore. My initial thought was that the barrel has a restriction possibly caused when by dent or a deformed dovetail.

Jag and Rod stuck in barrel