- Joined

- Jan 23, 2021

- Messages

- 186

- Reaction score

- 142

Question is, is this close enough or should I take it on down completely flat?

Seems as though I’m taking off a lot of metal. Not sure if the tolerance levels should be that precise.

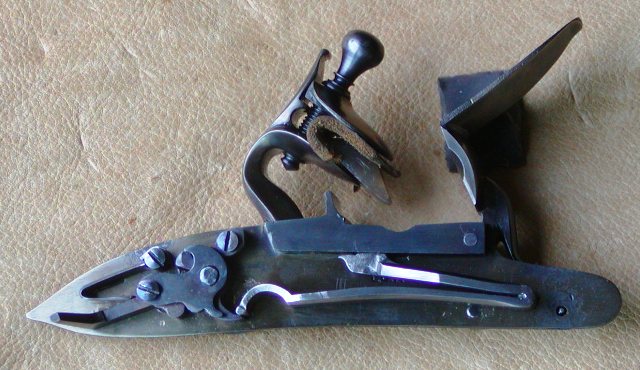

My first build… FYI…see pictures please.

Seems as though I’m taking off a lot of metal. Not sure if the tolerance levels should be that precise.

My first build… FYI…see pictures please.