Grayson Palmer

32 Cal

I searched for this, and I'm sure it has been discussed but I couldn't find it. Sorry if it is a repeat.

I'm nearly done building my first kit gun. It's a .54 caliber Lyman Great Plains Rifle percussion.

Lots of challenges for this newbie. But now I'm down to something I need to run by you guys before I mess something up.

There are several problems I'm having with the barrel fit.

As always, THANK YOU

I'm nearly done building my first kit gun. It's a .54 caliber Lyman Great Plains Rifle percussion.

Lots of challenges for this newbie. But now I'm down to something I need to run by you guys before I mess something up.

There are several problems I'm having with the barrel fit.

- With the tang screwed down, the barrel will not drop down into the stock. I understand this is a common issue. Lyman has a video explaining to back out the front and back screws on the tang. I did this but that didn't help unless I backed it way out several turns.

- I don't like the idea of having the tang riding so high above where it "should" seat. Something can't be quite right about that.

- A couple ideas on this...first being...maybe the rear/bottom of the barrel is touching the stock bed near the tang and I need to scrape out some wood so the barrel will lay flat. It's hard to put wood back in though so I haven't started this.

- Second idea, being a little wacky, I could put a block of metal (or wood) underneath the tang at the end where the barrel goes (the hex shaped part of the tang). I've toyed with this by putting a small nut in there and tightening down the tang to wedge it in place. This "seems" to work. The barrel dropped ALMOST into the stock, just a little spring back.

- I just thought of this. I could put some washers on the bolt that holds down the front of the tang. The washers would go UNDER the tang and therefore I could feel somewhat assured the tang was in the same place and not loose all the time. This option would do the same thing as my wacky spacer idea above and it would be a lot easier to find a few small washers than to make a perfect spacer.

- When I get the barrel into the stock (either with tang screws backed way out, or with the nut "spacer" under the hex end of the tang), a couple more issues exist. I actually think they exist if I just lay the barrel in the stock without the tang in place at all, but I need to check that.

- First being...the barrel wedges don't fit "right". I can push the rear wedge 95% in with my thumb and whack it with something and it goes right in. But then the front wedge just falls in...no resistance. I *think* whichever wedge I put in first is "good". But then the second is too loose.

- I've heard of the method of taking a round rod or dowel and laying it on the barrel lugs and bending them in to make them "tighter". Is that the proper method? I don't know whether the wedge should be tight in the lugs because they just barely fit through the lugs, OR if the wedges should be tight because the lugs just lack a little bit of lining up with the wedges. In other words, if you took out your barrel and put a wedge in the lug slot (no stock involved), does the wedge fall into the lug slot, or does it taking some pushing/tapping to get it in there?

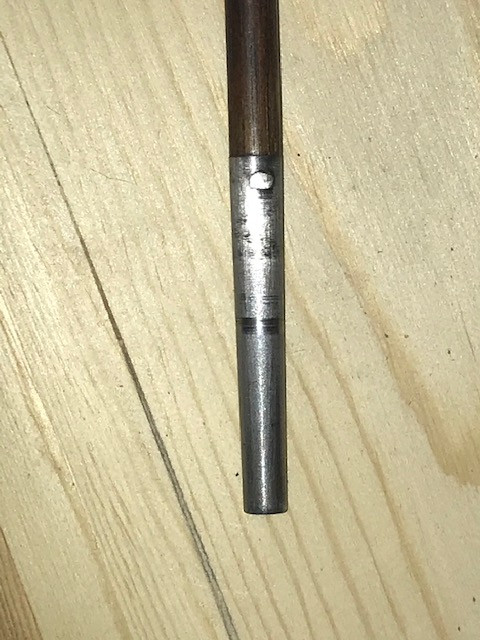

- Second issue is the ramrod. I have a brass ramrod that is made for this rifle. It hits the rear barrel lug and won't go any farther. Well...it WILL go farther but it's a pain to get it back out if you force it past the rear barrel lug.

- First being...the barrel wedges don't fit "right". I can push the rear wedge 95% in with my thumb and whack it with something and it goes right in. But then the front wedge just falls in...no resistance. I *think* whichever wedge I put in first is "good". But then the second is too loose.

As always, THANK YOU

8320AFCD-4D6B-4267-8064-CB5F6AA59DBD

8320AFCD-4D6B-4267-8064-CB5F6AA59DBD