- Joined

- Nov 26, 2005

- Messages

- 5,202

- Reaction score

- 10,785

Hi,

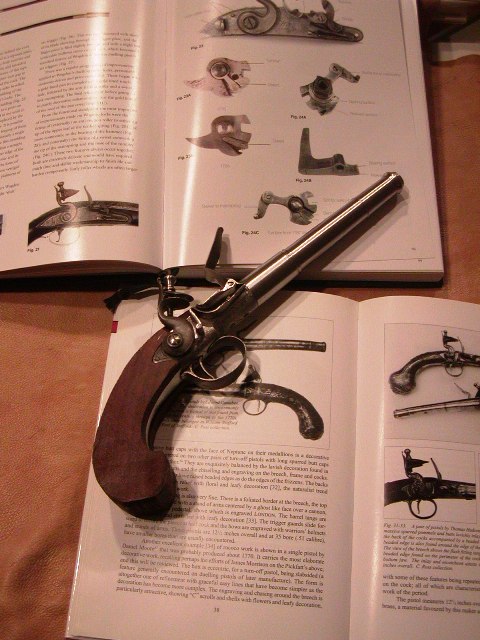

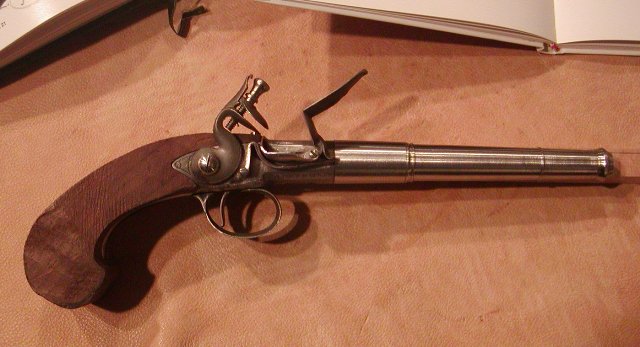

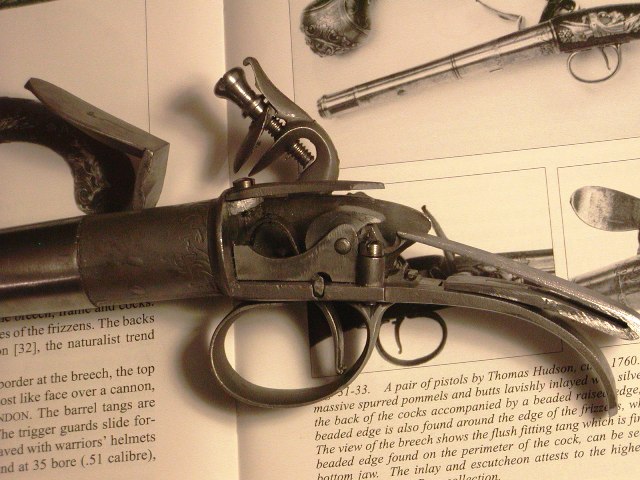

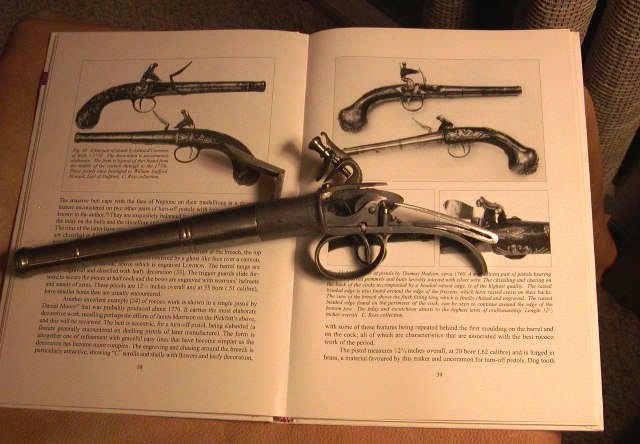

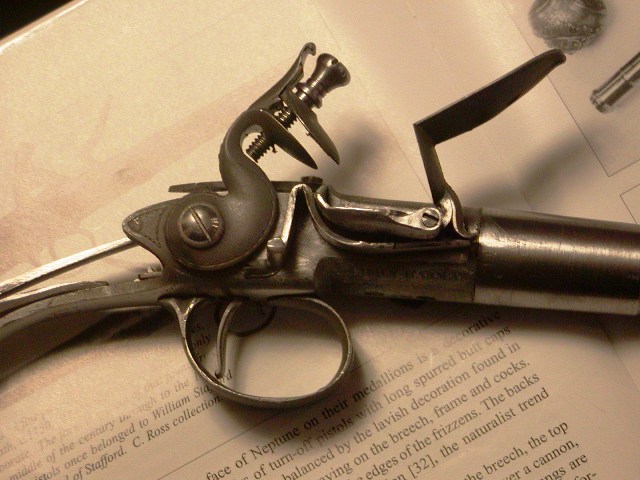

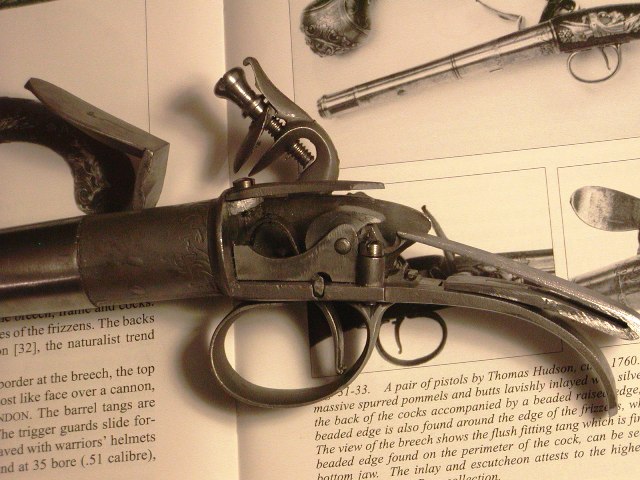

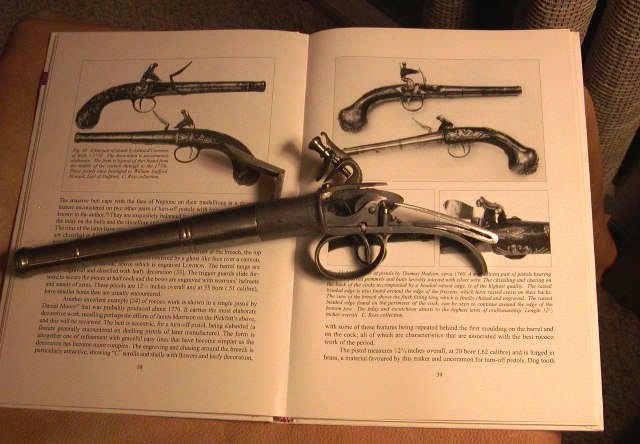

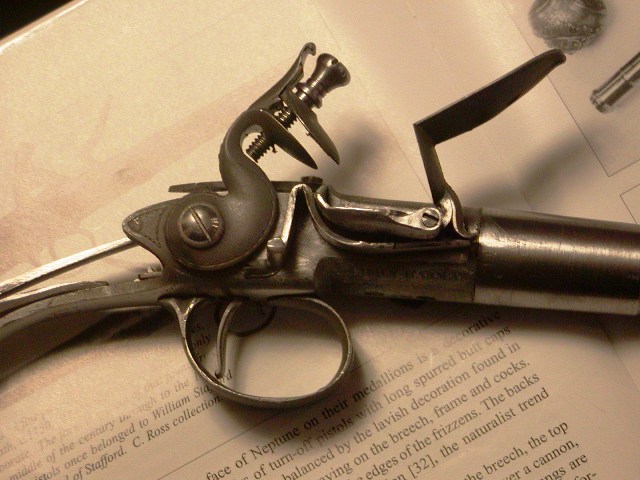

While also building an Edward Marshall rifle, I am working on this little gem. Breech loading side lock turn off pistols were the most popular civilian pistols made in England for over 100 years (1650-1770). Although decorative details changed over time, the basic design remained remarkably the same during that period. Like so many early technologies related to firearms, the French probably invented the design but the English refined it and made it work better than anyone else. My pistol is a mid 18th century design based on a pistol by John Harman, one of the best London makers. I made the action from parts cast by TRS with a few minor modifications and improvements. The decorative mounts will be silver that I will cast and chisel. The stock is modestly figured English walnut. I'll probably include silver wire inlay and of course will engrave the gun in the appropriate manner for the time and place. One of the first challenges was drilling the powder chamber and making the ball recess. That had to be concentric with the bore, which is 54 caliber. I calculated the powder chamber needed to be about 1/4" in diameter and 1 7/16" long so the end was perpendicular to the vent hole. That would hold about 20 grains of 3f powder. I used empty 6mm rifle cartridges and drilled out the primer holes and necks to 1/4 inch. The body of the cartridge fit the barrel perfectly. I place 2 of theses cartridges in the barrel, screwed it on the receiver, and inserted a 1/4" bell hanger's drill in the cartridges. They made perfect guides for the drill and centered it on the bore. I then drilled a hole 1 7/16" deep. Then I took a 1/2" drill and drilled the ball recess, finishing its shape and dimensions with 1/2" ball shaped grinding stones. It was not hard to use the stones to fit a 54 caliber ball. The depth of the recess had to be just sufficient to fit the ball and screw on the barrel such that the shoulder in the barrel just "kissed" the ball with the barrel fully tightened on the threads. These pistols are really well designed and the mechanism is strong and ingenious.

The decorative ribs on the barrel are a bit clumsy and cartoonish. They don't match any of the originals I've seen. Consequently, I turned the barrel today to reshape the ribs more correctly.

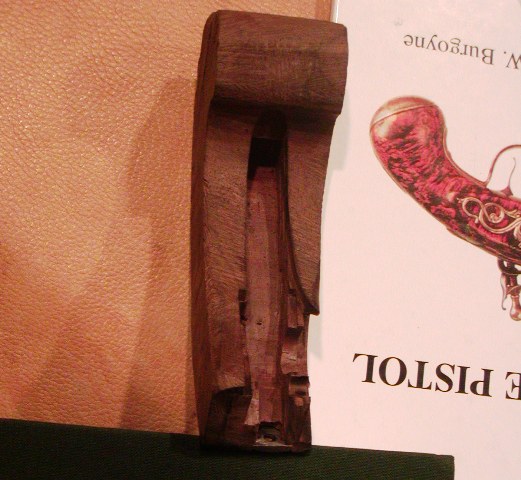

I also chose a nice piece of English walnut for the handle.

More to come.

dave

While also building an Edward Marshall rifle, I am working on this little gem. Breech loading side lock turn off pistols were the most popular civilian pistols made in England for over 100 years (1650-1770). Although decorative details changed over time, the basic design remained remarkably the same during that period. Like so many early technologies related to firearms, the French probably invented the design but the English refined it and made it work better than anyone else. My pistol is a mid 18th century design based on a pistol by John Harman, one of the best London makers. I made the action from parts cast by TRS with a few minor modifications and improvements. The decorative mounts will be silver that I will cast and chisel. The stock is modestly figured English walnut. I'll probably include silver wire inlay and of course will engrave the gun in the appropriate manner for the time and place. One of the first challenges was drilling the powder chamber and making the ball recess. That had to be concentric with the bore, which is 54 caliber. I calculated the powder chamber needed to be about 1/4" in diameter and 1 7/16" long so the end was perpendicular to the vent hole. That would hold about 20 grains of 3f powder. I used empty 6mm rifle cartridges and drilled out the primer holes and necks to 1/4 inch. The body of the cartridge fit the barrel perfectly. I place 2 of theses cartridges in the barrel, screwed it on the receiver, and inserted a 1/4" bell hanger's drill in the cartridges. They made perfect guides for the drill and centered it on the bore. I then drilled a hole 1 7/16" deep. Then I took a 1/2" drill and drilled the ball recess, finishing its shape and dimensions with 1/2" ball shaped grinding stones. It was not hard to use the stones to fit a 54 caliber ball. The depth of the recess had to be just sufficient to fit the ball and screw on the barrel such that the shoulder in the barrel just "kissed" the ball with the barrel fully tightened on the threads. These pistols are really well designed and the mechanism is strong and ingenious.

The decorative ribs on the barrel are a bit clumsy and cartoonish. They don't match any of the originals I've seen. Consequently, I turned the barrel today to reshape the ribs more correctly.

I also chose a nice piece of English walnut for the handle.

More to come.

dave