Swamp Buck

40 Cal.

- Joined

- Oct 31, 2005

- Messages

- 227

- Reaction score

- 0

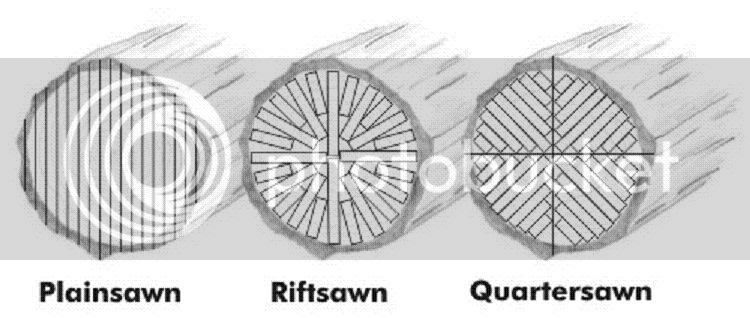

I have a question regarding the best way to cut/saw a maple tree to obtain stock blanks for muzzleloading gun stocks. I've heard of something called "quarter-sawn" - is that the best way to cut up the tree trunk to get the most usable stock blanks or is there another way?

Also, what would be the minimum diameter of a maple tree one would cut to obtain stock blanks.

I guess what I am looking for is a pattern I could use at some point in the future should the red maple trees I'm thinking about become available for cutting. These trees are at least 2 feet in diameter and even if the wood turned out fairly plain, they would have quite a bit of intrinsic historical value for our family.

Also, what would be the minimum diameter of a maple tree one would cut to obtain stock blanks.

I guess what I am looking for is a pattern I could use at some point in the future should the red maple trees I'm thinking about become available for cutting. These trees are at least 2 feet in diameter and even if the wood turned out fairly plain, they would have quite a bit of intrinsic historical value for our family.