As an interesting thing to do in my retirement from designing jet engines, I'm designing a matchlock Lock which might be suitable for a Caliver and I have a question of you experts.

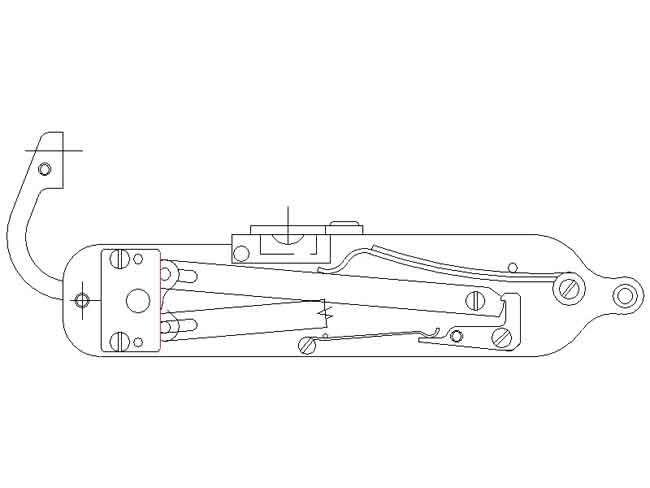

My current design has a spring loaded Serpintine which is released with a sear. The trigger would be a conventional design like a Flintlock uses.

To fire a gun with this lock you would move the serpentine from the "fired" or down position to the cocked position where the sear would latch. Pulling the trigger would release the sear which would return the surpentine to the fired position using the internal spring.

The force to cock the lock would be about 2 pounds at the serpentines head.

This might be called a Snap-Matchlock?

Did such a Lock ever exist during the Matchlock era?

Any thoughts about this idea?

Zonie

My current design has a spring loaded Serpintine which is released with a sear. The trigger would be a conventional design like a Flintlock uses.

To fire a gun with this lock you would move the serpentine from the "fired" or down position to the cocked position where the sear would latch. Pulling the trigger would release the sear which would return the surpentine to the fired position using the internal spring.

The force to cock the lock would be about 2 pounds at the serpentines head.

This might be called a Snap-Matchlock?

Did such a Lock ever exist during the Matchlock era?

Any thoughts about this idea?

Zonie