George91946

40 Cal.

- Joined

- Jan 7, 2010

- Messages

- 159

- Reaction score

- 1

Hello:

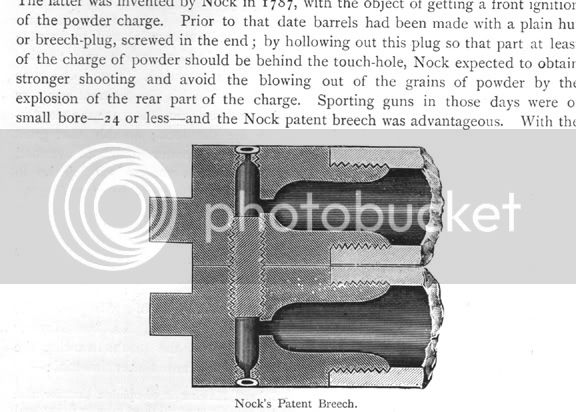

I've got a pistol with a Nock Breech. The vent goes into a chamber that connects to the powder load with a small 2 mm diameter channel about 4 to 5 mm in length. The pistol works ok for 10 to 15 shots, and then begins to hang fire, and get incomplete ignitions. I have to remove the vent plug and clean the chamber and the channel in order to get the pistol to fire well. Have you any suggestions on how to fix this ?

thanks

Lisle George

I've got a pistol with a Nock Breech. The vent goes into a chamber that connects to the powder load with a small 2 mm diameter channel about 4 to 5 mm in length. The pistol works ok for 10 to 15 shots, and then begins to hang fire, and get incomplete ignitions. I have to remove the vent plug and clean the chamber and the channel in order to get the pistol to fire well. Have you any suggestions on how to fix this ?

thanks

Lisle George