You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Paper Cartridge Dowel

- Thread starter nkvd

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

I am not quite sure what you are using the dowel to do? Is this a mandrill to make the paper cartridge? If so, then a 3/4" dowel is about as close in size as you are going to find.( 5/8 inch would normally be the next smallest diameter of dowel you will find.) Chuck a section of the dowel ;long enough to be your mandrill, into a wood lathe, or a drill press, and remove enough wood to allow for the thickness of the paper for the cartridge, and room to fit down the barrel of your gun. Just because a gun barrel says its .75 caliber, does not mean the bore diameter is actually .750"!

Measure, always.

Once you have the dowel trimmed down to make a good mandrill, cut your paper long enough to hold the bullet, or ball, and powder charge, leaving some extra to either tie, or fold over and glue shut.

I don't understand why the mandrill needs to have a hollow in either end. All you are doing is putting a RB into the paper cartridge, and then glueing or tying the end above it, and then tying a string behind it so that the ball remains separate from the powder charge. The cartridge is then removed from the mandrill, and the powder charge poured in. The open end of the cartridge is then folded over, and sometimes glued down. Many shooters lube the ball by dipping that end of the paper cartridge in melted beeswax, or paraffin.

Perhaps I am confused and you are talking about something else. If so, please excuse my ignorance, and accept my apology.

Measure, always.

Once you have the dowel trimmed down to make a good mandrill, cut your paper long enough to hold the bullet, or ball, and powder charge, leaving some extra to either tie, or fold over and glue shut.

I don't understand why the mandrill needs to have a hollow in either end. All you are doing is putting a RB into the paper cartridge, and then glueing or tying the end above it, and then tying a string behind it so that the ball remains separate from the powder charge. The cartridge is then removed from the mandrill, and the powder charge poured in. The open end of the cartridge is then folded over, and sometimes glued down. Many shooters lube the ball by dipping that end of the paper cartridge in melted beeswax, or paraffin.

Perhaps I am confused and you are talking about something else. If so, please excuse my ignorance, and accept my apology.

ohio ramrod

75 Cal.

- Joined

- Aug 21, 2008

- Messages

- 7,473

- Reaction score

- 2,213

for making paper cartridge tubes I use a tapered doll rod approximately .100 inch under the bore size tapered to bore size.If you have a lathe with a chuck or collets it is easy to taper the rod with a rasp and sand paper.

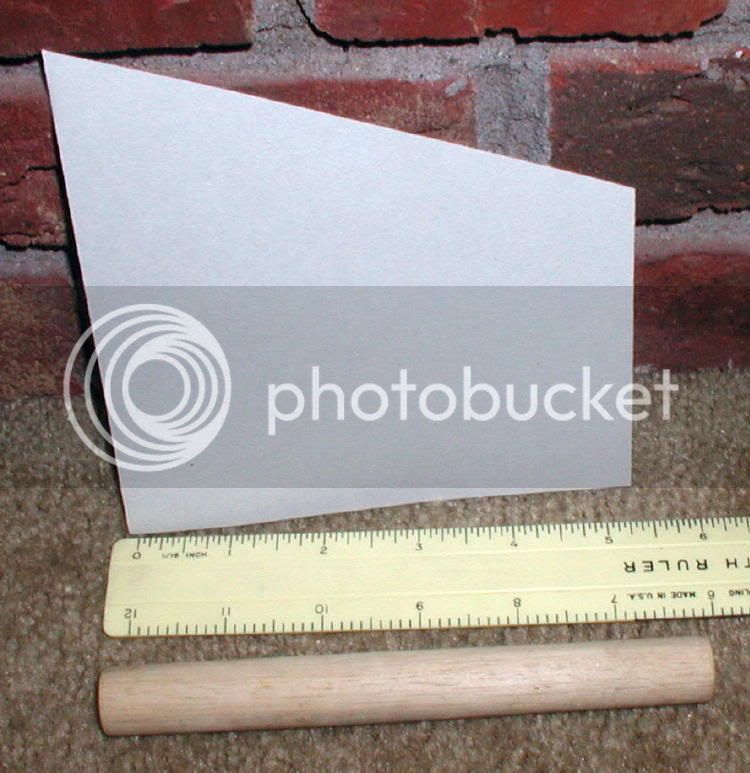

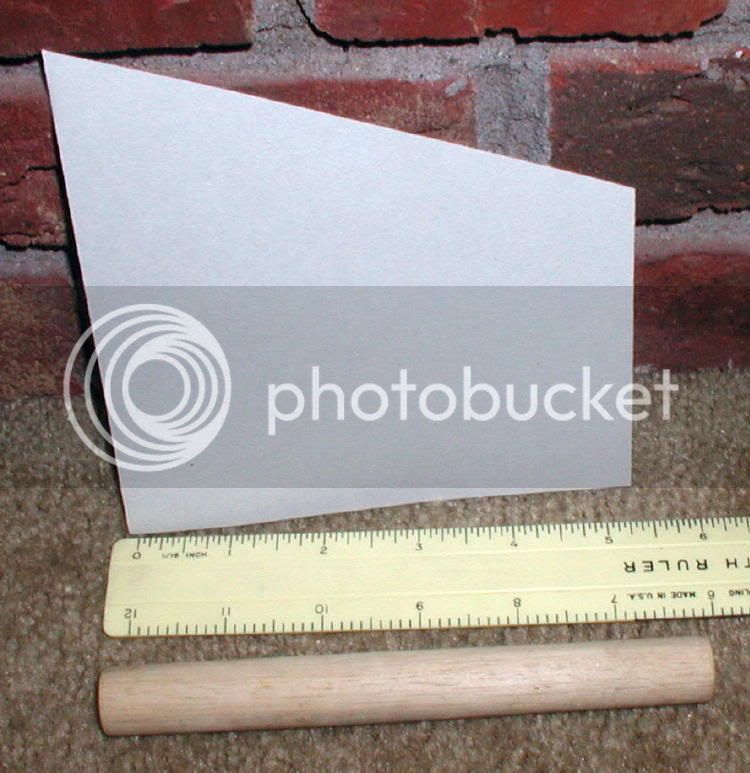

I make my cartridge former (mandrel) slightly larger than the size of the musket ball and when the paper (waste computer paper or news print) is wrapped around the ball, you will have a sliding fit in the bore. I use a 0.715" diameter ball and newsprint for the paper. The former is 0.720" in diameter and about 6" long. I measure between 85 and 90 grains (volume) of powder. I prime from a small horn when I load cartridges. When you seat the ball on the powder, the lubricant will hold the ball in place for the forst shot and the lube and fouling hold the ball for subsequent shots.

You can round one end and I like to dish the other end to help in positioning the ball. I hope these images help.

You can round one end and I like to dish the other end to help in positioning the ball. I hope these images help.

George Kevil

36 Cal.

- Joined

- Apr 30, 2005

- Messages

- 63

- Reaction score

- 0

Here's a link to making cartridges

http://www.najecki.com/40thfoot/Cartridge1.html

Last edited by a moderator:

George Kevil

36 Cal.

- Joined

- Apr 30, 2005

- Messages

- 63

- Reaction score

- 0

It is a way to make the tube.Just add powder and ball.

I've always wanted to make some cartridges for my fowler. I want to make them using shot though.

Ideally I'd just ram the paper down the barrel and it would become my wadding. I would probably pack an overpowder cards in the tube as well. The one thing I've never really understood though is how do you lube the paper? Just rub it on before you form the cartridge?

Ideally I'd just ram the paper down the barrel and it would become my wadding. I would probably pack an overpowder cards in the tube as well. The one thing I've never really understood though is how do you lube the paper? Just rub it on before you form the cartridge?

George Kevil said:Here's a link to making cartridges http://www.najecki.com/40thfoot/Cartridge1.html

Was this particular size and set of dimensions for a .58cal?

Last edited by a moderator:

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

YOu can't Oil or grease a paper tube without it contaminating the powder, eventually.

Some shooters dip the ball end of the " cartridge " into melted beeswax, or parafin wax, and then let it cool. The wax serves as a bore lubricant. ( Bore butter, for instance, is half wax, and about half oil. Wax is a common additive to patch lubes.)

You would be much better off using Jim Rackham's system in your fowler. Using ONLY OS cards, which he pokes with an awl to give each card an off-center hole that allows air to pass through the card, use 4 cards over the powder, and 2 over your shot. He puts a ball of waxy lube between the 3rd and 4th cards on top of the powder charge, and lets the lube be squeezed between the two cards to grease the barrel as the gun is fired. The cards allow you to use these in barrels that have chokes at the muzzle, because the thin cards can be bent slightly to fit through the chokes, before being turned and seated down the barrel. Protecting the edges of the wads is what makes wads do their job. Put the 4 wads in so that the holes DON't Line up. I purposely set the holes at 12,3,6,&9 O'clock positions at the muzzle as they are passed into the barrel. The two cards on top of the shot have their holes set at 12&6 o'clock. The holes do let the air pass out from behind the cards, so that the air does not break an edge instead. The thin cards weigh so little that they quickly fall away from the line of fire, whether shooting shot, or PRBs. Jim posted pictures of his excellent patterns using OS cards, and one picture of a typical pattern he got using the more traditional wad combinations( we all have used). The OS Card patterns were noticeably better patterns.

Of course, you have to test these things in your own gun. I found, for instance, that my 20 gauge fowler is actually a 19 gauge fowler! I only got it to shoot at all when I bought larger diameter cards.

My gunmaker was shocked at what I found, as he ordered my barrel from the same supplier as had provided him a barrel for his own fowler. We pulled that gun off his gunrack and measured the barrel, and it came in at .615" the correct dimension for a 20 gauge barrel. Mine is .626! I took my gun to his shop just so he could measure it with his own calipers, rather than trusting my measurements. Circle Fly makes wads and cards in just about every gauge, so getting the 19 gauge OS cards( and some OP wads to use with PRB) was not all that difficult.

Some shooters dip the ball end of the " cartridge " into melted beeswax, or parafin wax, and then let it cool. The wax serves as a bore lubricant. ( Bore butter, for instance, is half wax, and about half oil. Wax is a common additive to patch lubes.)

You would be much better off using Jim Rackham's system in your fowler. Using ONLY OS cards, which he pokes with an awl to give each card an off-center hole that allows air to pass through the card, use 4 cards over the powder, and 2 over your shot. He puts a ball of waxy lube between the 3rd and 4th cards on top of the powder charge, and lets the lube be squeezed between the two cards to grease the barrel as the gun is fired. The cards allow you to use these in barrels that have chokes at the muzzle, because the thin cards can be bent slightly to fit through the chokes, before being turned and seated down the barrel. Protecting the edges of the wads is what makes wads do their job. Put the 4 wads in so that the holes DON't Line up. I purposely set the holes at 12,3,6,&9 O'clock positions at the muzzle as they are passed into the barrel. The two cards on top of the shot have their holes set at 12&6 o'clock. The holes do let the air pass out from behind the cards, so that the air does not break an edge instead. The thin cards weigh so little that they quickly fall away from the line of fire, whether shooting shot, or PRBs. Jim posted pictures of his excellent patterns using OS cards, and one picture of a typical pattern he got using the more traditional wad combinations( we all have used). The OS Card patterns were noticeably better patterns.

Of course, you have to test these things in your own gun. I found, for instance, that my 20 gauge fowler is actually a 19 gauge fowler! I only got it to shoot at all when I bought larger diameter cards.

My gunmaker was shocked at what I found, as he ordered my barrel from the same supplier as had provided him a barrel for his own fowler. We pulled that gun off his gunrack and measured the barrel, and it came in at .615" the correct dimension for a 20 gauge barrel. Mine is .626! I took my gun to his shop just so he could measure it with his own calipers, rather than trusting my measurements. Circle Fly makes wads and cards in just about every gauge, so getting the 19 gauge OS cards( and some OP wads to use with PRB) was not all that difficult.

Va.Manuf.06

58 Cal.

The cartridge is not meant to be rammed whole so no need to lube the entire thing. Tear the tail off, pour the powder down the barrel and ram the ball wrapped with the paper if you can. You will need to use a consistent thickness paper if you intend to leave it wrapped around the ball, as suggested, the ball/paper combination should be a fit allowing the paper covered ball to be rammed easily, not too tight. Beeswax is best but paraffin will do if it is all you can get - dip the ball end only after the cartridge is loaded. Most important, don't cheap out, newsprint will be a waist of time, it tears too easily. Use a high rag content paper so the wax will not wick down the paper containing the powder, that will contaminate the powder and give you inconsistent accuracy.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

Yep! That is how its done, from what I have seen and heard. I never got into that type of shooting, but spent hours with guys who did. And one friend was kind enough to show me how he make the paper cartrdiges much as you have described, and what has been pictured here. He was using parafin, but I offered him some Beeswax. He had just ordered some beeswax, so he declined my offer, but said if he ran out, he would remember to give me a call. I have several pounds of Beeswax that my father scrounged from one place or another.

Captain outwater

40 Cal.

- Joined

- Aug 7, 2006

- Messages

- 138

- Reaction score

- 1

Depends on what you want to do with the cartridge...Are you going to put them in a cartridge box? The former should be less than 75 cal. so the finish cartridge fits into a cartridge box, if that is what you are going to use. I use a 3/8 brass tube myself.

The ball sits nicely on it, and you can press the other end together after loading the powder- I like to pull the former out slightly and then crimp the paper again, like a shotgun shell, which insures the powder won't come out in handling. You can leave a tail on it to pull out so you don't have to bite into powder.

The ball sits nicely on it, and you can press the other end together after loading the powder- I like to pull the former out slightly and then crimp the paper again, like a shotgun shell, which insures the powder won't come out in handling. You can leave a tail on it to pull out so you don't have to bite into powder.

A couple of pics of that approach would be nice as well if you get a chanceCaptain Outwater said:Depends on what you want to do with the cartridge...Are you going to put them in a cartridge box? The former should be less than 75 cal. so the finish cartridge fits into a cartridge box, if that is what you are going to use. I use a 3/8 brass tube myself.

The ball sits nicely on it, and you can press the other end together after loading the powder- I like to pull the former out slightly and then crimp the paper again, like a shotgun shell, which insures the powder won't come out in handling. You can leave a tail on it to pull out so you don't have to bite into powder.

bebloomster

40 Cal.

- Joined

- Sep 2, 2008

- Messages

- 131

- Reaction score

- 0

I've gone through a lot of different "recipes" looking for the ideal paper cartridge lube. Various combinations of olive oil, beeswax, parafin, lard and the like. My cartridge has always been made with 2 wraps of recycled news print. A .715 ball with the end of the tube folded and glued down over it. 85gr GOEX FFFg for a powder charge.

Lubing was done by dipping only the ball end of the cartridge into the molten lube and then letting it cool. Most of the lubes would allow maybe a half dozen shots before the fouling would be so bad that I couldn't get another paper wrapped ball down the bore. Cleaning would bring up fouling that was very hard and shiny black... always looked like carbon or coal to me.

The only lube that has worked well for me is Crisco brand shortening. Melt some down and dip only the ball end of the paper cartridge in it. I've gotten up to 40 shots in a row without having to run a patch down the bore and the fouling has always been soft.

The real disadvantage though is once dipped in the Criso the paper cartridge will have a somewhat limited shelf life. Within a couple months the Crisco will wick through the paper and contaminate the powder charge. My current practice is to go ahead and make up 100 cartridges including ball and powder but NOT dip them in the Crisco lube. They are stored in one of those GI 50 caliber ammo cans. MTM makes black plastic inserts designed to hold 50 12ga shotshells and these inserts will fit into the GI ammo can if they are slightly reduced in width. Then when I am getting ready to go do some shooting I will dip as many cartridges as I plan on shooting and them put them into one of those plastic ammo boxes that holds 25 12ga shotshells. Or will just go ahead and put up to 40 of them in my cartridge shoulder bag.... it has 2 wood blocks that hold 20 each, one block on top of the other in the bag.

The main thing that I try to do is NOT lube more cartridges than I will fire in a month.

Lubing was done by dipping only the ball end of the cartridge into the molten lube and then letting it cool. Most of the lubes would allow maybe a half dozen shots before the fouling would be so bad that I couldn't get another paper wrapped ball down the bore. Cleaning would bring up fouling that was very hard and shiny black... always looked like carbon or coal to me.

The only lube that has worked well for me is Crisco brand shortening. Melt some down and dip only the ball end of the paper cartridge in it. I've gotten up to 40 shots in a row without having to run a patch down the bore and the fouling has always been soft.

The real disadvantage though is once dipped in the Criso the paper cartridge will have a somewhat limited shelf life. Within a couple months the Crisco will wick through the paper and contaminate the powder charge. My current practice is to go ahead and make up 100 cartridges including ball and powder but NOT dip them in the Crisco lube. They are stored in one of those GI 50 caliber ammo cans. MTM makes black plastic inserts designed to hold 50 12ga shotshells and these inserts will fit into the GI ammo can if they are slightly reduced in width. Then when I am getting ready to go do some shooting I will dip as many cartridges as I plan on shooting and them put them into one of those plastic ammo boxes that holds 25 12ga shotshells. Or will just go ahead and put up to 40 of them in my cartridge shoulder bag.... it has 2 wood blocks that hold 20 each, one block on top of the other in the bag.

The main thing that I try to do is NOT lube more cartridges than I will fire in a month.

Similar threads

- Replies

- 12

- Views

- 765

- Replies

- 7

- Views

- 948