Couple questions from a new guy:

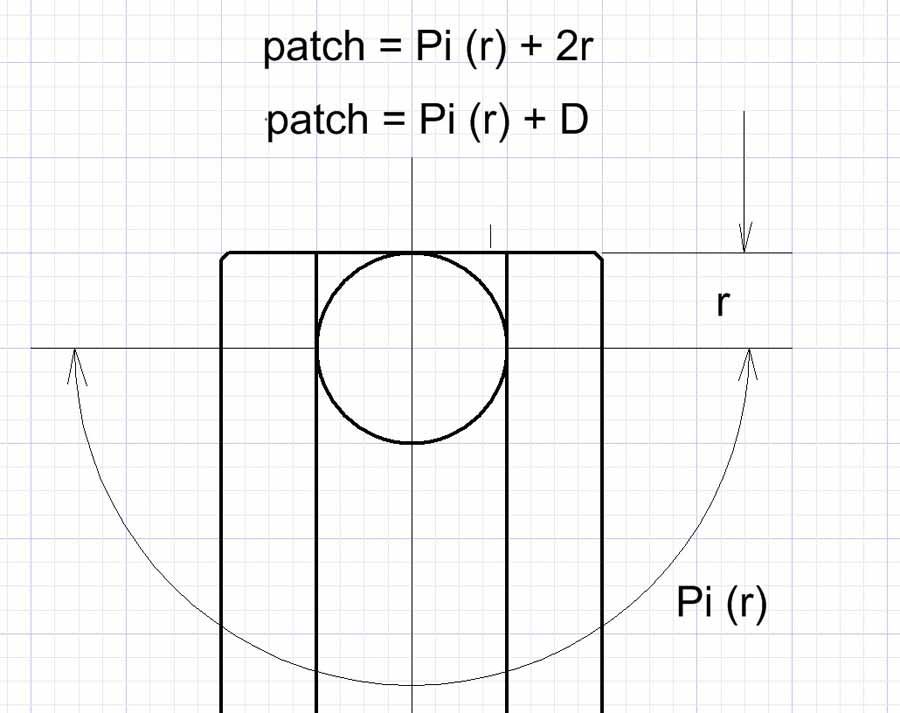

1. Getting ready to cut some strips of teflon patching and wondered how wide to make them for cutting off at the end of the barrel after starting the ball on a 54 cal.

2. What size square do you cut flannel cleaning patch material for cleaning between shots on standard jag for 54 cal

Thx

wirebrush

1. Getting ready to cut some strips of teflon patching and wondered how wide to make them for cutting off at the end of the barrel after starting the ball on a 54 cal.

2. What size square do you cut flannel cleaning patch material for cleaning between shots on standard jag for 54 cal

Thx

wirebrush