IMO, if the hole in line with the bore is the same size as the bore J.D. is right.

On the other hand, the idea behind the original Patent Breech was that if a small chamber contained powder which was ignited first, the very hot flame from it shooting thru the main powder charge would be more effective in igniting that main charge.

To that end, Mr. Nock in 1787 created just such a chamber.

Because he patented it no one could use his design without paying him royalties.

Other builders, wanting to stay abreast of the latest ideas created the chambered breech that is commonly used on modern sidelocks and often called a patent breech.

The bottom line is, if the hole that is in line with the bore is much smaller than the bore it will be a chambered breech and in theory it will ignite the main charge more effectively.

Some tests have been done over the years and guns using these chambered breeches and the Patent breech do seem to create less fouling in their bores. Now, whether they are "better" is a matter that probably will never be resolved.

Knowing the problems some folks have with their chambered breeches with their long intersecting flame channels I personally lean towards the short connection that is typical of a side vented flintlock or a side drum percussion.

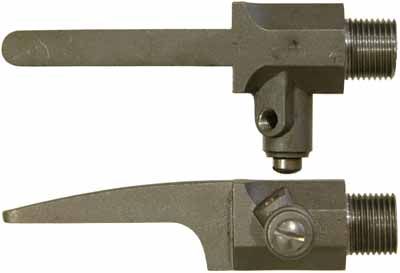

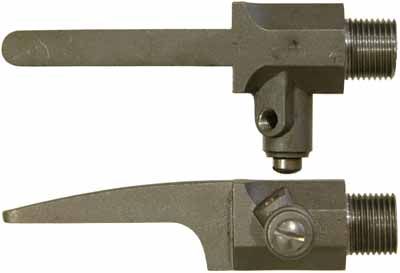

The breech shown in the photo is no doubt much sturdier than a screwed in side drum but that added strength has a weight penalty that goes along with it.

In the side drum and the breech shown in the photo both will have to be accurately installed so that they are fully supported by the lockplate.

This brings up the installation of this breech plug.

Because the projection is already "installed" its location is fixed. That means the lock will have to be located and installed based on the existing fixed drum.

This gives little room for error.

This is one of the reasons that building any percussion gun with a scroll breach or a Bar Lock is more difficult than building a percussion gun with a screw in drum.

A hole for a threaded side drum on the other hand can be shifted (before it is drilled), locating it to create a good alignment with the lockplate even if that plate is installed slightly high or low.