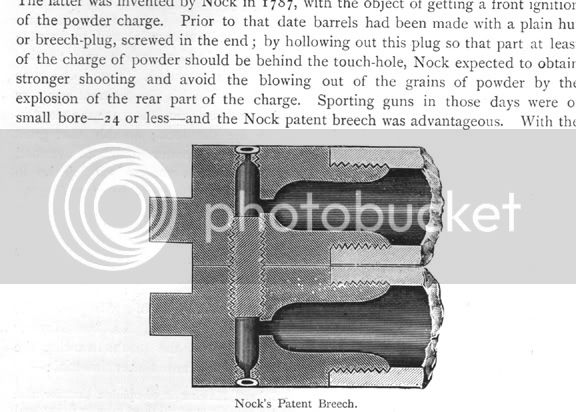

I have been searching the forum archives to learn more about patent breeches (an amusing aside... do a general internet search on the topic, and most of the useful pages are previous threads from this forum :thumbsup . As a good intro w/ good images, I refer you to the thread "Patent Breech" posted in Feb 2007. That thread discussed the Nock Patent Breech for flintlocks which brings ignition from the side flash hole, into an antechamber behind the charge, and through a forward-facing hole into a cone-shaped chamber containing the powder charge.

. As a good intro w/ good images, I refer you to the thread "Patent Breech" posted in Feb 2007. That thread discussed the Nock Patent Breech for flintlocks which brings ignition from the side flash hole, into an antechamber behind the charge, and through a forward-facing hole into a cone-shaped chamber containing the powder charge.

Most of our modern replica guns (T/C, Investarms/Cabelas, Pedersoli, Traditions, etc.) have patent breeches, and I wanted to know what they were and why. I now know generally what they are. However, I am not firing a flintlock, and I know my patent breech is not a "Nock" style for several reasons (it is part of the barrel and not the breech plug, no cleanout screw opposite the flash hole, etc).

So, I have a few questions:

1) Does the modern patent breech function similarly to the Nock design with an antechamber and ignition of the powder charge from the rear rather than the side of the charge?

2) Does anyone know the physics behind, and benefits of, the patent breech design?

3) Builders such as S. Nock included, what is the history of the patent breech? Any other good designers? Why design it?

4) I feel a definite shoulder about one inch from the rear-most end of the breech. The smoothly coned edges of classic patent breech images don't include this shoulder. I wonder about their design. Are the walls just a narrower cylinder w/ a flat bottom? Is the back wall actually coned down to a hole that delivers the flash? And what purpose would a flat-faced patent breech scraper serve against a tapered/coned breech end (other than gouging a circle in it)?

This is not a thread on how to clean a patent breech or which patent breech is more authentic than another. I really want to learn the nitty-gritty about the design, purpose, functionality, and "modern" application of the idea.

Again, I appreciate any insight you may offer :hatsoff:.

Most of our modern replica guns (T/C, Investarms/Cabelas, Pedersoli, Traditions, etc.) have patent breeches, and I wanted to know what they were and why. I now know generally what they are. However, I am not firing a flintlock, and I know my patent breech is not a "Nock" style for several reasons (it is part of the barrel and not the breech plug, no cleanout screw opposite the flash hole, etc).

So, I have a few questions:

1) Does the modern patent breech function similarly to the Nock design with an antechamber and ignition of the powder charge from the rear rather than the side of the charge?

2) Does anyone know the physics behind, and benefits of, the patent breech design?

3) Builders such as S. Nock included, what is the history of the patent breech? Any other good designers? Why design it?

4) I feel a definite shoulder about one inch from the rear-most end of the breech. The smoothly coned edges of classic patent breech images don't include this shoulder. I wonder about their design. Are the walls just a narrower cylinder w/ a flat bottom? Is the back wall actually coned down to a hole that delivers the flash? And what purpose would a flat-faced patent breech scraper serve against a tapered/coned breech end (other than gouging a circle in it)?

This is not a thread on how to clean a patent breech or which patent breech is more authentic than another. I really want to learn the nitty-gritty about the design, purpose, functionality, and "modern" application of the idea.

Again, I appreciate any insight you may offer :hatsoff:.