-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ram Rod for Pedersoli 50 cal Hawken

- Thread starter 1860 Army

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Black Hand

Cannon

- Joined

- Mar 17, 2005

- Messages

- 9,348

- Reaction score

- 896

Is this a problem?6 Shot said:I'm particular. 1/4" will make it stick out beyond the muzzle.

If needed - shorten the rammer...

$11.99

$13.01

Traditions Performance Firearms Muzzleloader Stainless #11 Nipples with M6x1threads - 2 per - for Traditions and CVA rifles and pistols

National Hardware Supply

$15.99

Muzzle-Loaders Wooden Black Powder Muzzleloader Bullet and Sabot Starter - 6 Jags

IX Properties

$11.99

$13.01

Traditions Performance Firearms Muzzleloader Stainless #11 Nipples with M6x1threads - 2 per - for Traditions and CVA rifles and pistols

National Hardware Supply

If you are going to be that particular, and nothing wrong with that, you are better off like others said to get one and finish cutting it to the length you want.

I don't have any tools to shorten it.

Called Cabelas. Even though my rifle is in warranty, they don't have a replacement ramrod. Had me call the distributor for Pedersoli. They too had no replacement ramrod. Thy said that this rifle is made for Cabela's. I bought one for a CVS from Track of the Wolf. Will deal with the 1/4" difference.

Very disappointed that I can't keep it original. :surrender:

Called Cabelas. Even though my rifle is in warranty, they don't have a replacement ramrod. Had me call the distributor for Pedersoli. They too had no replacement ramrod. Thy said that this rifle is made for Cabela's. I bought one for a CVS from Track of the Wolf. Will deal with the 1/4" difference.

Very disappointed that I can't keep it original. :surrender:

for a 1/4 inch you can probably just sit on yer lawn and grind off the 1/4" on the sidewalk? Go slow but if ya aint even got a swiss army knife saw ya gotta use concrete.

Black Hand

Cannon

- Joined

- Mar 17, 2005

- Messages

- 9,348

- Reaction score

- 896

Just go with the rammer that is slightly longer. It really doesn't make any difference...6 Shot said:I don't have any tools to shorten it.

Called Cabelas. Even though my rifle is in warranty, they don't have a replacement ramrod. Had me call the distributor for Pedersoli. They too had no replacement ramrod. Thy said that this rifle is made for Cabela's. I bought one for a CVS from Track of the Wolf. Will deal with the 1/4" difference.

Very disappointed that I can't keep it original. :surrender:

Nothing wrong with a rod sticking out beyond the muzzle, IMO.

I replaced my Lyman GPR with a glass rod. It isn't PC, but it won't break and stab my hand. At least I think I replaced it, the rod I have now may have been the original.

You can get a dowel at your Local Hardware Store. If you flex it a bit you can tell if it will break under pressure. The dowels are Ramin wood, a Philippine hardwood, and may cost as much as two bucks. The 3/8" rods will work and if need be you can shave them down with a pocket knife or a piece of broken glass to fit your rifle. You can get hardware from TOW or use that off your broken rod.

Having broken a rod and stabbed my hand severely, I'm all about brass range rods. I'm decidedly not a PC guy.

ToW is an excellent source but shipping for a long blank is pretty high. I live where hickory grows and is available for shaping, which with a raw billet is pretty time-consuming. I've got a lot of Osage orange which I'm sure would make a great ramrod. So would yew.

I replaced my Lyman GPR with a glass rod. It isn't PC, but it won't break and stab my hand. At least I think I replaced it, the rod I have now may have been the original.

You can get a dowel at your Local Hardware Store. If you flex it a bit you can tell if it will break under pressure. The dowels are Ramin wood, a Philippine hardwood, and may cost as much as two bucks. The 3/8" rods will work and if need be you can shave them down with a pocket knife or a piece of broken glass to fit your rifle. You can get hardware from TOW or use that off your broken rod.

Having broken a rod and stabbed my hand severely, I'm all about brass range rods. I'm decidedly not a PC guy.

ToW is an excellent source but shipping for a long blank is pretty high. I live where hickory grows and is available for shaping, which with a raw billet is pretty time-consuming. I've got a lot of Osage orange which I'm sure would make a great ramrod. So would yew.

I am also all about brass ram-rods.

I had a very close shave last year hunting where my ramrod broke and came within a hair of impaling my hand. Dumb luck saved me.

I know the loading rules, I know not to grab the ram-rod high up and not try and force it all at once...but I had adrenaline pumping, looking at a deer that ignored being shot at and looking to try a second shot. All good sense went out the window and that ram-rob broke off in a nasty spear point.

Now my hunting rifle has a brass rod. Yes it adds some weight, but my hunting spot is about 200 yards from where I am sitting and I just hunt from my spot. A heavier rifle isn't too much a big deal for me all things considered.

I had a very close shave last year hunting where my ramrod broke and came within a hair of impaling my hand. Dumb luck saved me.

I know the loading rules, I know not to grab the ram-rod high up and not try and force it all at once...but I had adrenaline pumping, looking at a deer that ignored being shot at and looking to try a second shot. All good sense went out the window and that ram-rob broke off in a nasty spear point.

Now my hunting rifle has a brass rod. Yes it adds some weight, but my hunting spot is about 200 yards from where I am sitting and I just hunt from my spot. A heavier rifle isn't too much a big deal for me all things considered.

nwtradegun

50 Cal.

- Joined

- Jan 19, 2011

- Messages

- 1,496

- Reaction score

- 17

Last edited by a moderator:

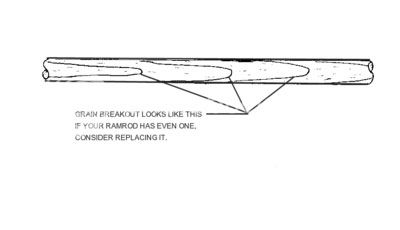

Most of you probably know this but for the few that don't:

Hickory and many other hardwoods branches consist of hundreds (or thousands) of long fibers, growing side by side.

These are often referred to as the grain of the wood.

In branches that are pretty much the same size from one end to the other, these fibers are usually continuous from one end to the other. Imagine hundreds of soda straws bundled together, side by side.

Trying to break a branch across the grain ranges from pretty easy to damn near impossible depending on the kind of wood.

I have an ash tree in my front yard and just a moderate sideways push across a dry branch will snap it off in a heartbeat. That would fit the pretty easy category so this trees wood would make horrible ramrods.

Good woods like Hickory rate in the damn near impossible to snap in too category which is why they have been used for hundreds of years to make ramrods.

That said, the resistance to breaking requires the fibers (grain) to be running from one end to the other.

The only good way to be sure this is happening is to split the wood blank.

By starting a lengthwise cut at one end of the blank, just prying the grain fibers away from the other fibers will cause them to split off of the main body in one long strip.

This is where the factory made ramrods and dowels from your local hardware/lumber store fail.

Rather than splitting the excess wood away, using the strength of the grain to remove the excess, modern methods take the blank and toss it into a machine.

The machine doesn't know or care which way the grain is running. It just knows it should hog off anything larger than the size it is set to produce.

That ends up cutting across the woods grain, leaving short lengths that are easily split off of their neighboring grains.

Even a good hard push along the length of a ramrod made this way can cause the fibers to break away from their neighbors, just like splitting them would and if they do, the remaining, very sharp end can impale you.

When companies machine the dowels, the outside of the rod/dowel will have a characteristic grain pattern showing.

It looks like this:

If you see this kind of pattern on your guns ramrod or on the dowel you are thinking about buying, run away!

Well, maybe not run away but don't use it as a ramrod.

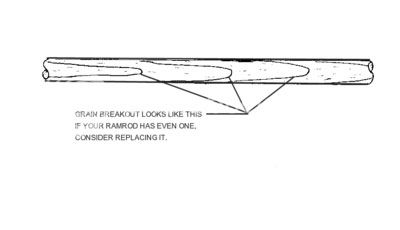

Hickory and many other hardwoods branches consist of hundreds (or thousands) of long fibers, growing side by side.

These are often referred to as the grain of the wood.

In branches that are pretty much the same size from one end to the other, these fibers are usually continuous from one end to the other. Imagine hundreds of soda straws bundled together, side by side.

Trying to break a branch across the grain ranges from pretty easy to damn near impossible depending on the kind of wood.

I have an ash tree in my front yard and just a moderate sideways push across a dry branch will snap it off in a heartbeat. That would fit the pretty easy category so this trees wood would make horrible ramrods.

Good woods like Hickory rate in the damn near impossible to snap in too category which is why they have been used for hundreds of years to make ramrods.

That said, the resistance to breaking requires the fibers (grain) to be running from one end to the other.

The only good way to be sure this is happening is to split the wood blank.

By starting a lengthwise cut at one end of the blank, just prying the grain fibers away from the other fibers will cause them to split off of the main body in one long strip.

This is where the factory made ramrods and dowels from your local hardware/lumber store fail.

Rather than splitting the excess wood away, using the strength of the grain to remove the excess, modern methods take the blank and toss it into a machine.

The machine doesn't know or care which way the grain is running. It just knows it should hog off anything larger than the size it is set to produce.

That ends up cutting across the woods grain, leaving short lengths that are easily split off of their neighboring grains.

Even a good hard push along the length of a ramrod made this way can cause the fibers to break away from their neighbors, just like splitting them would and if they do, the remaining, very sharp end can impale you.

When companies machine the dowels, the outside of the rod/dowel will have a characteristic grain pattern showing.

It looks like this:

If you see this kind of pattern on your guns ramrod or on the dowel you are thinking about buying, run away!

Well, maybe not run away but don't use it as a ramrod.

The illustration is the "rift" of a round shaft. The straight grain is the "reed."

A dowel will show both, and of course the best method is to split a piece of hickory and round it off and then straighten it with heat and steam...or both.

I dug a Ramin dowel out, a 3/8" dowel I got from the hardware store. It shows the rift pretty clearly. I bent this dowel to test it's breaking strength, and it passed with flying colors. In fact, I could make a bow without it breaking. It had a fistmele of about two inches, which indicates the extent to which the dowel was bent. I wouldn't shoot it and raw it back, but the dowel would work just fine for a ramrod, which is why I bought it.

So I think I flexed the dowel at the hardware store, but it's been so long I've forgotten. I flexed it far more than a ramrod would flex.

Hickory is best, makes a great selfbow and a great ramrod. But ramin will work if you test it.

A dowel will show both, and of course the best method is to split a piece of hickory and round it off and then straighten it with heat and steam...or both.

I dug a Ramin dowel out, a 3/8" dowel I got from the hardware store. It shows the rift pretty clearly. I bent this dowel to test it's breaking strength, and it passed with flying colors. In fact, I could make a bow without it breaking. It had a fistmele of about two inches, which indicates the extent to which the dowel was bent. I wouldn't shoot it and raw it back, but the dowel would work just fine for a ramrod, which is why I bought it.

So I think I flexed the dowel at the hardware store, but it's been so long I've forgotten. I flexed it far more than a ramrod would flex.

Hickory is best, makes a great selfbow and a great ramrod. But ramin will work if you test it.

Similar threads

- Replies

- 3

- Views

- 557

SOLD - Pending funds

Leather Journal

- Replies

- 0

- Views

- 176