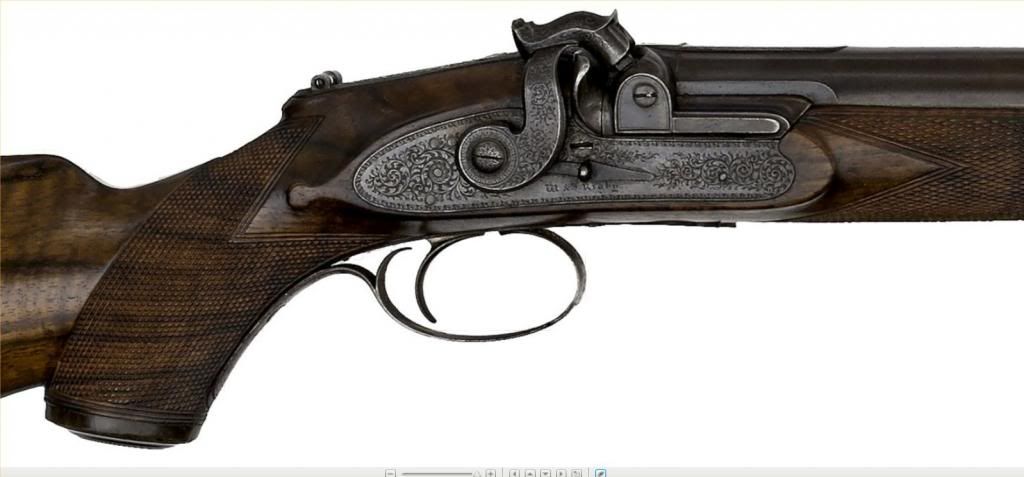

This rifle I purchased a few weeks ago. It had a broken hammer spur. I wanted to restore the hammer back to original condition. I don't have the talent to do this work, but the great thing is I know a guy that does have the talent.

The hammer is currently at the engravers, and then off to be color cased.

The pictures speak for themselves.

Fleener

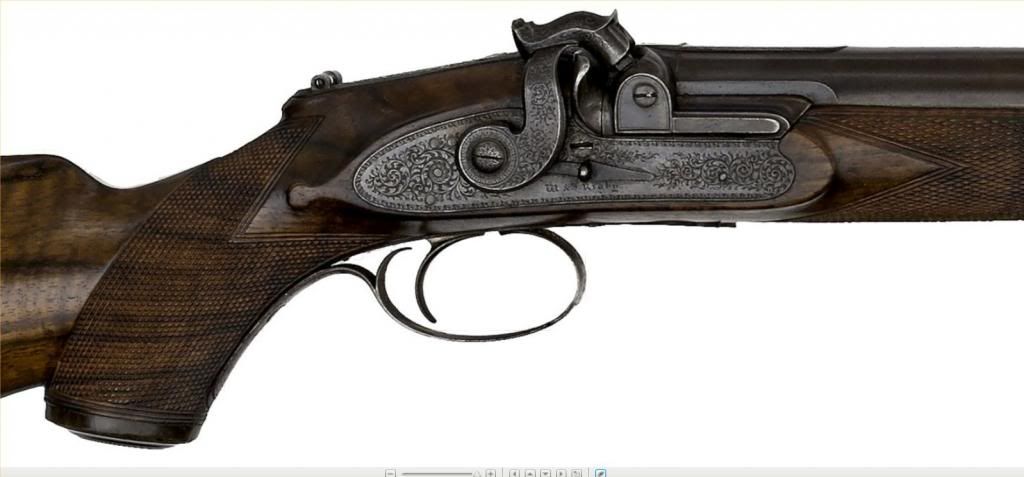

The hammer is currently at the engravers, and then off to be color cased.

The pictures speak for themselves.

Fleener