My daughter bought a mass production kit percussion pistol. I have that exact gun, bought already finished. It has two ugly round threaded bushings on the left side, where the lock screws come out.

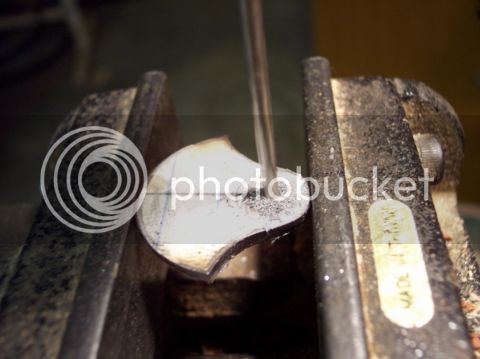

It seems to me that I could saw and file a homemade side plate in an afternoon. Thread it and install it proud of the wood - then only if it works out - I would inlet it.

I'd practice on my gun. I'm reasonably handy. I have drilled and tapped holes before. So I'm sure I could do it.

The question is what thickness of steel should I use? Is the soft stuff I could buy at the hardware store OK?

It seems to me that I could saw and file a homemade side plate in an afternoon. Thread it and install it proud of the wood - then only if it works out - I would inlet it.

I'd practice on my gun. I'm reasonably handy. I have drilled and tapped holes before. So I'm sure I could do it.

The question is what thickness of steel should I use? Is the soft stuff I could buy at the hardware store OK?