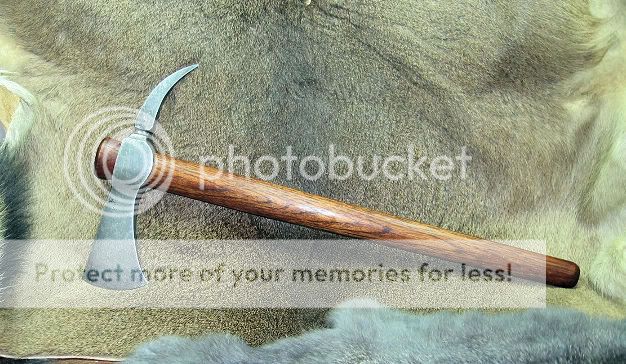

Here's a spike tomahawk the I made by reforging a 24oz ball peen hammer. It sure beats having to slit and drift the eye. I do however redrift the eyes bigger to accept a regular tear drop shaped hawk handle. The handle is made from hickory.

I heat treat like 1045Joe Mandt said:Nice work! What kind of steel is it?

Enter your email address to join: