Technical discussion about "Recess / Jug / Tulip" choke designs in Smoothbore muzzleloader barrels.

Over the years I have learned how these chokes are made...have seen sketches like the one below...have looked into Jug Choked bores...and have used Jug Chokes in different barrels (Full and Imp. Cyl PLUS). And I know they work, are effective, etc.

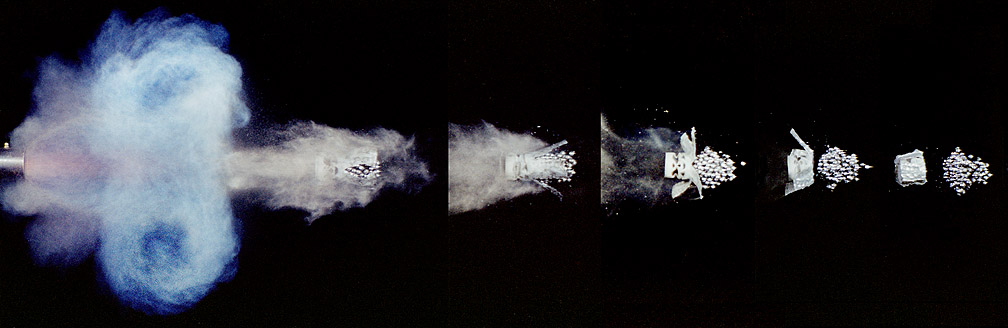

I understand that the shot charge expands into the expansion chamber and is then forced back down to the original bore size at the muzzle before muzzle exit. BUT.....what I'm not 100% certain about is what 'physics' are at play, what 'dynamics' take place on the shot charge...that even though the shot charge is still exiting at original cylinder bore size...the pattern is more dense at longer distances.

The only understanding I seem to hang on to is that the outer layers of the shot charge begin to ever so slightly start to slow down as they expand into the larger diameter expansion chamber...while the central core of the shot charge is continuing ahead at full speed.

Then at the forward end of the expansion chamber, the whole of the larger diameter of the shot charge is tapered/necked back down on the back half/back end of the central core of the shot charge and in essence simply makes a longer shot string which pours more shot onto the center line of the shot column headed towards the target.

We know that modern "constrictor" type chokes like ImpCyl/Mod/Full/Extra Full are literally / physically smaller than cylinder bore and act on the shot charge as a forcing cone.

I also know the muzzle end of the expansion chamber in a Jug Choke does the same thing.

HOWEVER...the huge difference is that the muzzle end / exit is still at wide open Cylinder Bore.

Does anybody really know of an official description that confirms or is different from the physics / dynamics I'm struggling with?

What actually happens to the shot charge that makes it "act like" its coming out of a physically smaller Full constrictor choke size diameter...putting more shot into a smaller area at distance...when in reality it's actually still exiting a wide open cylinder bore opening?

RECESS / JUG / TULIP CHOKE IN A CYLINDER BORE BARREL

Over the years I have learned how these chokes are made...have seen sketches like the one below...have looked into Jug Choked bores...and have used Jug Chokes in different barrels (Full and Imp. Cyl PLUS). And I know they work, are effective, etc.

I understand that the shot charge expands into the expansion chamber and is then forced back down to the original bore size at the muzzle before muzzle exit. BUT.....what I'm not 100% certain about is what 'physics' are at play, what 'dynamics' take place on the shot charge...that even though the shot charge is still exiting at original cylinder bore size...the pattern is more dense at longer distances.

The only understanding I seem to hang on to is that the outer layers of the shot charge begin to ever so slightly start to slow down as they expand into the larger diameter expansion chamber...while the central core of the shot charge is continuing ahead at full speed.

Then at the forward end of the expansion chamber, the whole of the larger diameter of the shot charge is tapered/necked back down on the back half/back end of the central core of the shot charge and in essence simply makes a longer shot string which pours more shot onto the center line of the shot column headed towards the target.

We know that modern "constrictor" type chokes like ImpCyl/Mod/Full/Extra Full are literally / physically smaller than cylinder bore and act on the shot charge as a forcing cone.

I also know the muzzle end of the expansion chamber in a Jug Choke does the same thing.

HOWEVER...the huge difference is that the muzzle end / exit is still at wide open Cylinder Bore.

Does anybody really know of an official description that confirms or is different from the physics / dynamics I'm struggling with?

What actually happens to the shot charge that makes it "act like" its coming out of a physically smaller Full constrictor choke size diameter...putting more shot into a smaller area at distance...when in reality it's actually still exiting a wide open cylinder bore opening?

RECESS / JUG / TULIP CHOKE IN A CYLINDER BORE BARREL