I have a well-worn question to ask, but it has a special wrinkle to it that I believe makes it worth asking. Sorry about the length of this post, but the details seem important.

My 54 cal. flintlock (EuroArms 1803) is an absolute bear to load and I usually resort to a rawhide mallet to load a .530 ball with a .016 pillow ticking patch. The patches are soaked in 1 to 6 Ballistol/water mixture and allowed to dry most of the way. I also clean briefly in between shots. I'm a strong guy, but even the slightest amount of fouling makes it impossible to load this thing without using the mallet, and that includes having to start the ball by whacking the short starter with the mallet. I have slugged the bore twice, and also made a Cerosafe cast of the bore about 4 inches down the muzzle. These slugs show that my bore is .545 and the groove diameter is barely .552. If my slugs are accurate...my grooves are only .003 deep. The rifle has a 1 in 72 rate of twist with 8 lands and 8 grooves. I can often shoot 50 yard groups that are around, or slightly smaller, than 1.5 inches. I'm now using a felt overpowder wad and that has helped handle the 90 grs of 3f that has proven to be the most accurate load.

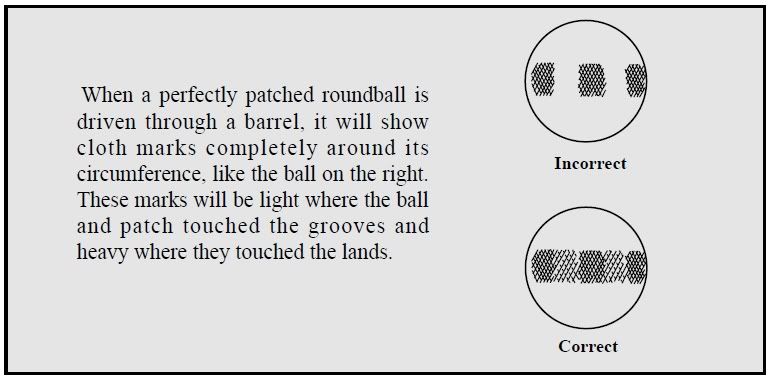

I've seated and pulled balls with my present ball/patch combination and it appears my patch is still not being forced into the grooves. (I don't see the pattern of the fabric impressed onto the ball except where the lands were). I've also wrapped my .016 patch around the ball and measured it with medium pressure and it shows I'm .003 short of filling the groove diameter. I'm wondering if my oversized bore (.545 instead of .540) is not displacing patch that would ordinarily be going into the grooves of most other 54 caliber rifles. By the book...it appears I need to increase my patch thickness even though I already have a very difficult time loading it with a .016 patch!

I'm just wondering if there is any chance that going to a .535 ball with a thinner patch would make it easier to load, without sacrificing any accuracy. Including the cost of shipping, it will cost me $24.00 for 100 .535 balls and there is no place I can buy them off the shelf. I've read that a barrel with very shallow grooves is hard to load, presumably because you are pushing hard against a lot of groove surface area, instead of land surface area. This rifle initially had sharp lands near the breech that frequently cut patches, and even left deep cuts on a very tight-fitting, brass ball seating spin jag. I recently gave the barrel 50 round trips with a maroon Scotch Brite pad and now the spin jag that I beleive is approx .525 dia now passes much more easily. I haven't shot it since I used the Scotch Brite, but I hope this will solve the patch cutting problem, and maybe even make it load more easily.

Loading with a mallet is not the end of the world I guess, as I get good accuracy. I've made sure that the concaves on my short starter, and on my ramrod seating jag fit the contour of my ball perfectly, so my use of the mallet never deforms the ball. It would be nice to load this thing without a mallet though. Some guys laugh when you get out a hammer!

My 54 cal. flintlock (EuroArms 1803) is an absolute bear to load and I usually resort to a rawhide mallet to load a .530 ball with a .016 pillow ticking patch. The patches are soaked in 1 to 6 Ballistol/water mixture and allowed to dry most of the way. I also clean briefly in between shots. I'm a strong guy, but even the slightest amount of fouling makes it impossible to load this thing without using the mallet, and that includes having to start the ball by whacking the short starter with the mallet. I have slugged the bore twice, and also made a Cerosafe cast of the bore about 4 inches down the muzzle. These slugs show that my bore is .545 and the groove diameter is barely .552. If my slugs are accurate...my grooves are only .003 deep. The rifle has a 1 in 72 rate of twist with 8 lands and 8 grooves. I can often shoot 50 yard groups that are around, or slightly smaller, than 1.5 inches. I'm now using a felt overpowder wad and that has helped handle the 90 grs of 3f that has proven to be the most accurate load.

I've seated and pulled balls with my present ball/patch combination and it appears my patch is still not being forced into the grooves. (I don't see the pattern of the fabric impressed onto the ball except where the lands were). I've also wrapped my .016 patch around the ball and measured it with medium pressure and it shows I'm .003 short of filling the groove diameter. I'm wondering if my oversized bore (.545 instead of .540) is not displacing patch that would ordinarily be going into the grooves of most other 54 caliber rifles. By the book...it appears I need to increase my patch thickness even though I already have a very difficult time loading it with a .016 patch!

I'm just wondering if there is any chance that going to a .535 ball with a thinner patch would make it easier to load, without sacrificing any accuracy. Including the cost of shipping, it will cost me $24.00 for 100 .535 balls and there is no place I can buy them off the shelf. I've read that a barrel with very shallow grooves is hard to load, presumably because you are pushing hard against a lot of groove surface area, instead of land surface area. This rifle initially had sharp lands near the breech that frequently cut patches, and even left deep cuts on a very tight-fitting, brass ball seating spin jag. I recently gave the barrel 50 round trips with a maroon Scotch Brite pad and now the spin jag that I beleive is approx .525 dia now passes much more easily. I haven't shot it since I used the Scotch Brite, but I hope this will solve the patch cutting problem, and maybe even make it load more easily.

Loading with a mallet is not the end of the world I guess, as I get good accuracy. I've made sure that the concaves on my short starter, and on my ramrod seating jag fit the contour of my ball perfectly, so my use of the mallet never deforms the ball. It would be nice to load this thing without a mallet though. Some guys laugh when you get out a hammer!