I picked up this decent (apparently no long made) Dixie Gun Works flintlock lock for a fair price. It's for a pistol build and is the right size of 4-3/4" long. The same\similar size to a L&R Manton lock that I have on a scaled down (kid\small frame person) 45-Cal flintlock rifle.

So, the lock plate started out as this, and I wanted it to look slimmer. You can see my marker that gave me the rough outline of the metal I wanted removed

After some filing the shape is more what I want. A slimmer look

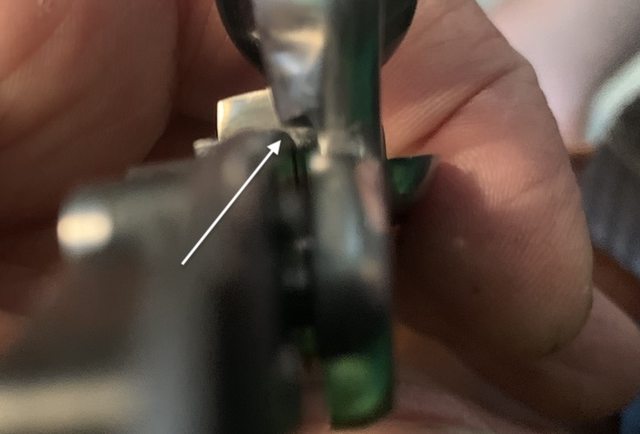

During the tuning\polishing phase I noticed the lock offset was not coming to rest on the bolster, but instead, the tumbler would stop the forward motion (of course, the frizzen would be hit first...but you never know!!

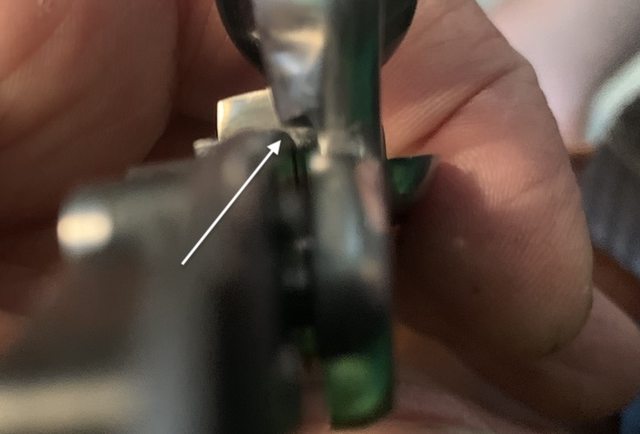

So I (at the suggestion of the good people at ALR) decided to hard solder (Silver solder) a piece on the bolster so the **** offset would come to rest where it should, and not the tumbler against the Bridle.

So, after the solder.....it's "Clean up on Isle 3" (old guys will get that). It cleaned up well (to about 90% now....I'll finish it post inletting), all contact points are polished and the lock functions well, spark's well, and the poundage to trip the sear bar is in line with my other locks. I think the little bump won't be all that noticeable on the pistol.

So, the lock plate started out as this, and I wanted it to look slimmer. You can see my marker that gave me the rough outline of the metal I wanted removed

After some filing the shape is more what I want. A slimmer look

During the tuning\polishing phase I noticed the lock offset was not coming to rest on the bolster, but instead, the tumbler would stop the forward motion (of course, the frizzen would be hit first...but you never know!!

So I (at the suggestion of the good people at ALR) decided to hard solder (Silver solder) a piece on the bolster so the **** offset would come to rest where it should, and not the tumbler against the Bridle.

So, after the solder.....it's "Clean up on Isle 3" (old guys will get that). It cleaned up well (to about 90% now....I'll finish it post inletting), all contact points are polished and the lock functions well, spark's well, and the poundage to trip the sear bar is in line with my other locks. I think the little bump won't be all that noticeable on the pistol.