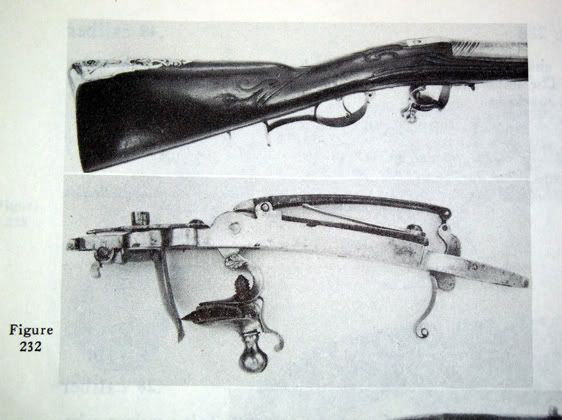

Without having the lock in my hands, it's just a guess but first I'll say I don't believe that there is a pin for a link on the back area of the trigger. If there were a pin or hinge joint at that location, and the large piece extending upwards thru the triggerplate towards the sear arm were itself a link, then I don't understand why there was a need for the small link connecting it at the top to the sear arm.

I believe the trigger and the material above the triggerplate is all one piece and it extends all the way thru the triggerplate up to the small link attaching it to the sear bar.

I also think the trigger extends back to some point behind the small pin that looks to be about 1/2 inch behind the trigger and is going thru the triggerplate. This, I believe, is the pivot for the trigger.

This arrangement will cause the trigger, the small upper link and the sear bar to rotate downwards when the trigger is pulled.

As the rear of the sear bar rotates downward, it pivots on the forward pin which raises the sear nose upward, away from the cocks half cock or full cock notch.

The "upper" blade of the spring forces the sear bar upwards causing the sear nose to engage the cocks notches. This movement raises the rear area of the sear arm which in effect, makes it the trigger spring.

Just a guess, but it works in my mind.