Erzulis boat

45 Cal.

- Joined

- Jul 14, 2005

- Messages

- 566

- Reaction score

- 78

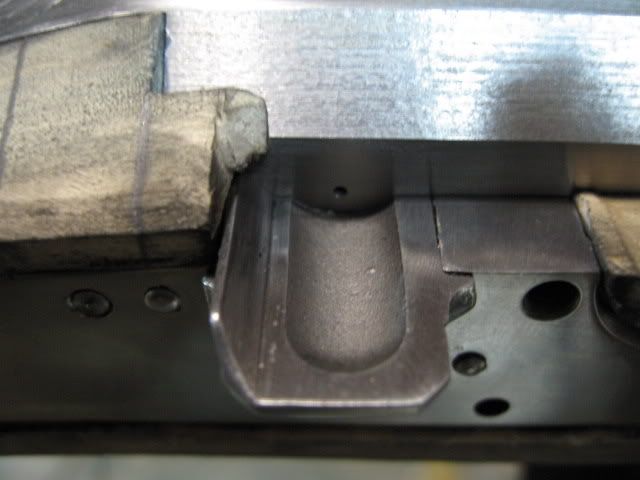

This depicts the indicated location of the ventliner (Chambers- White Lightning), and was done with the lock installed within the stock mortise. This assembled image shows the relation of the lock/barrel/lockscrews in a clear setting.

You will note that I have not really cleaned up or polished the barrel tang junction yet. As the breechplug will be removed during the install. Save the fine cosmetics for last.

The vent will be located in the center of the octagonal flat, and since the barrel is swamped, the center measurement must be taken at the vent hole location. The width of my flat at this spot measured .460, so .230 bisects the flat.

This is the tool layout for the drilling and tapping. I chose the 5/16" or .3125 diameter vent liner, as the size will be pleasing to the eye on the rather large barrel. The 1/4" vent available would also be fine.

The brass shimstock is the differential thickness of the "swamp" on the near vise jaw, and the barrel flat on the back jaw is in full contact.

Some builders will remove the breechplug for the drilling and tapping, but since the mill is so solid and accurate, I can forego this step. It is your choice.

I start with a small drill, then drill again undersize, then run a reamer before tapping. The reamer is not required, but since I had one laying around, I used it.

If your drill press has a lot of indicated run-out, a reamer might be in order, as the fine pitch (32 TPI) large diameter fasteners and ventliners require a more accurate hole(dimensionally) than would a "coarse" fastener.

As long as it is not a sloppy fit, you will be fine. Chambers ventliners measure maximum dimension on diameter/thread root etc. A very quality product.