- Joined

- Nov 26, 2005

- Messages

- 5,225

- Reaction score

- 10,888

Hi Folks,

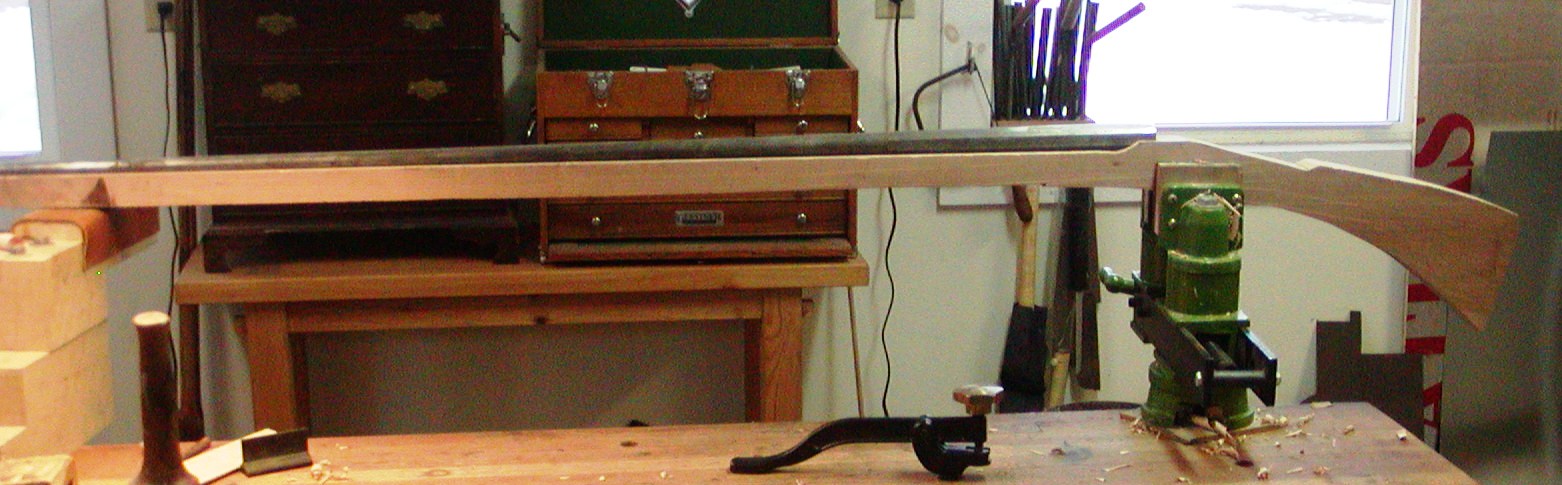

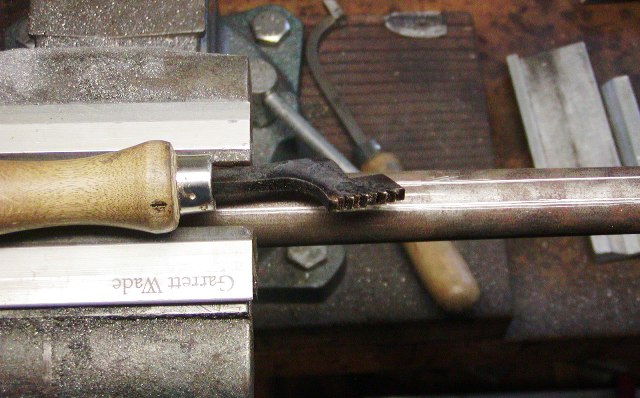

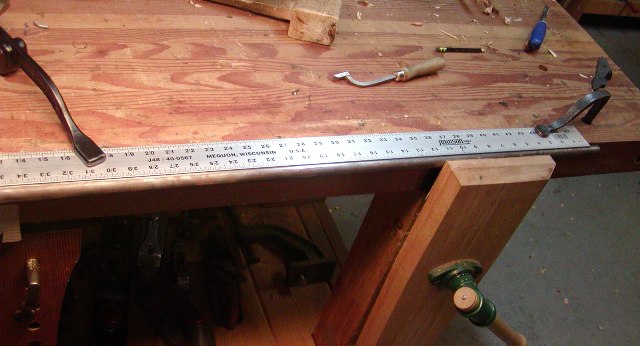

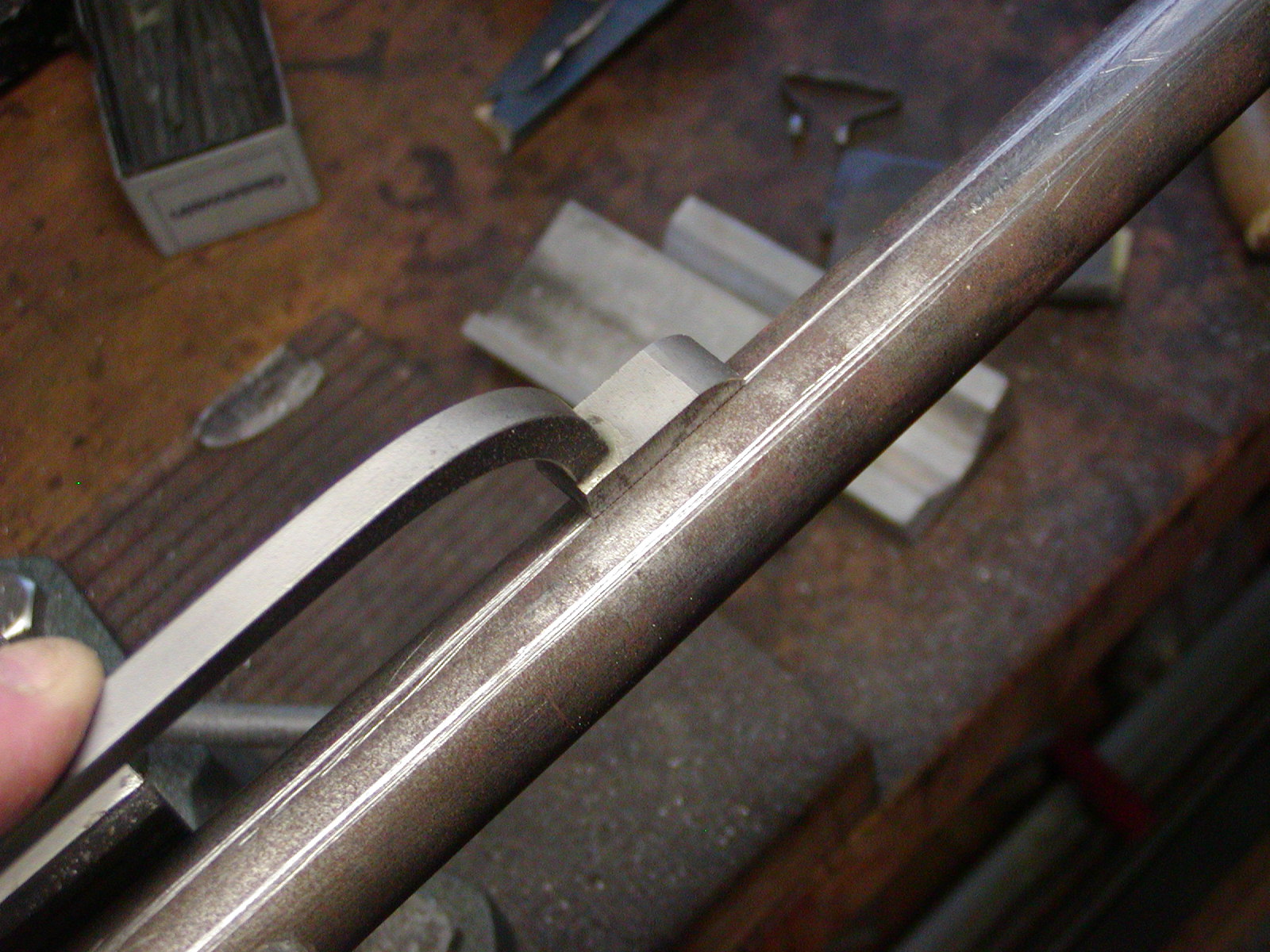

I am starting a new thread about building an historical New England fowler. I am making a gun inspired by the Jonathan Hawke's fowler on display at the Historic Deerfield Memorial Hall in Deerfield MA. Beth Gilgun allowed me to view the original up close and along with historian, Richard Colten, I was able to analyze and understand its properties thoroughly. I am building the gun for a member of the 40th regiment of foot, one of the best living history units representing British troops. He also portrays a French officer during the F&I wars and desires a gun that could double as a French officer's privately made gun as well as a colonial militia gun owned by a prosperous volunteer. A Connecticut River Valley gun such as the Hawke's fowler with heavy French influences will do the job. Below are photos of the original gun. I am adapting a TOW Tulle lock, some commonly available cast French hardware, and a 48" 20 gauge barrel from R. E. Davis. The original Hawke's fowler had a French made barrel 57" long. For practical reasons, I am going shorter but I will shape the barrel to resemble the original. The stock will be black cherry logged in Vermont. This thread will evolve slowly at first as I finish my current work.

dave

I am starting a new thread about building an historical New England fowler. I am making a gun inspired by the Jonathan Hawke's fowler on display at the Historic Deerfield Memorial Hall in Deerfield MA. Beth Gilgun allowed me to view the original up close and along with historian, Richard Colten, I was able to analyze and understand its properties thoroughly. I am building the gun for a member of the 40th regiment of foot, one of the best living history units representing British troops. He also portrays a French officer during the F&I wars and desires a gun that could double as a French officer's privately made gun as well as a colonial militia gun owned by a prosperous volunteer. A Connecticut River Valley gun such as the Hawke's fowler with heavy French influences will do the job. Below are photos of the original gun. I am adapting a TOW Tulle lock, some commonly available cast French hardware, and a 48" 20 gauge barrel from R. E. Davis. The original Hawke's fowler had a French made barrel 57" long. For practical reasons, I am going shorter but I will shape the barrel to resemble the original. The stock will be black cherry logged in Vermont. This thread will evolve slowly at first as I finish my current work.

dave