- Joined

- Mar 7, 2007

- Messages

- 729

- Reaction score

- 2,341

Back in 2016 I was commissioned to build a brass barreled blunderbuss. Here is the link to the original posts

https://www.muzzleloadingforum.com/threads/blunderbuss.103402/

The fellow who I made this for has contacted me again about a smaller version. He happened across an original blunderbuss that was significantly smaller and lighter than then one I built for him in the link above. Here are some details:

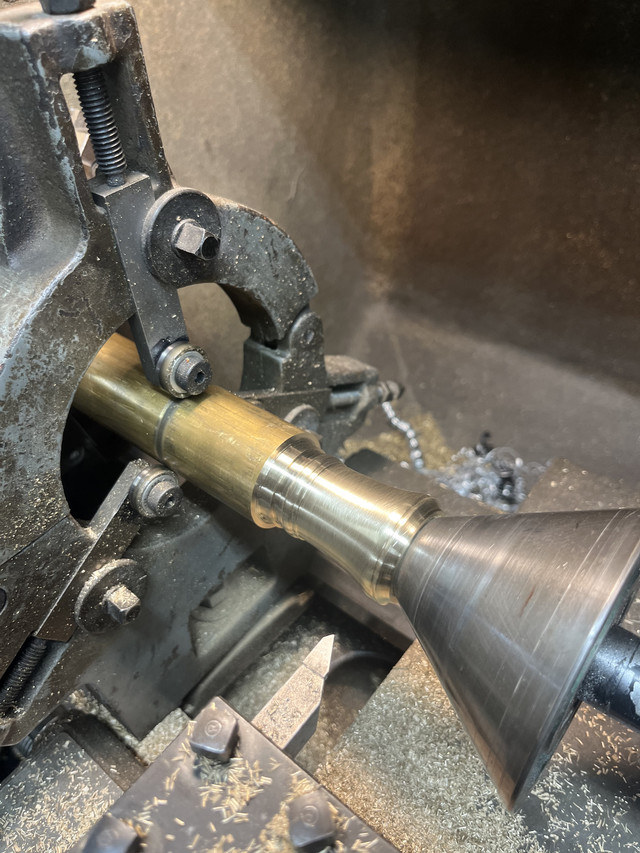

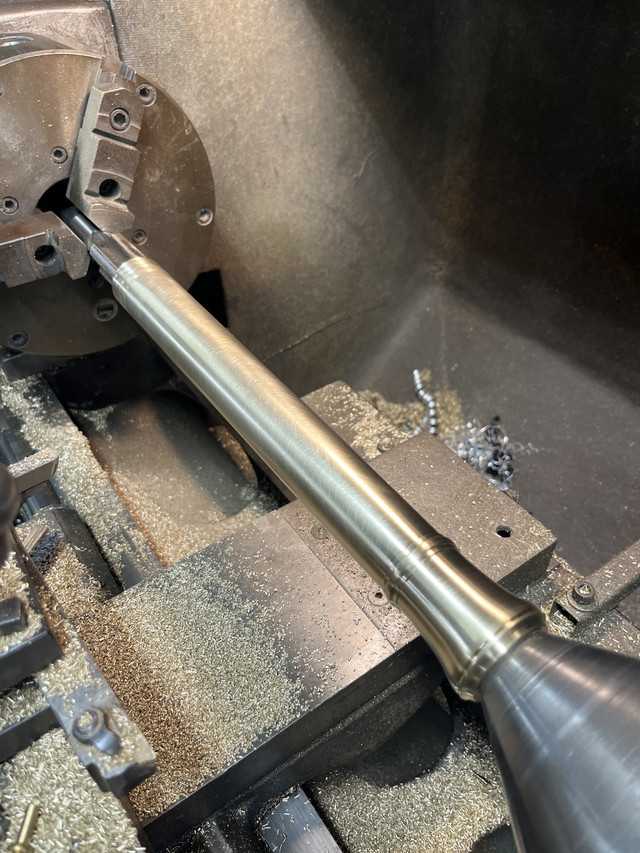

Brass cannon barrel 12.5” long with clear proof & view marks and engraved “LONDON”

Brass mounts in good condition

Lock is marked “NICHOLSON” and is in excellent working condition

Back of the lock marked “IW”

Excellent wood, no cracks and no missing pieces

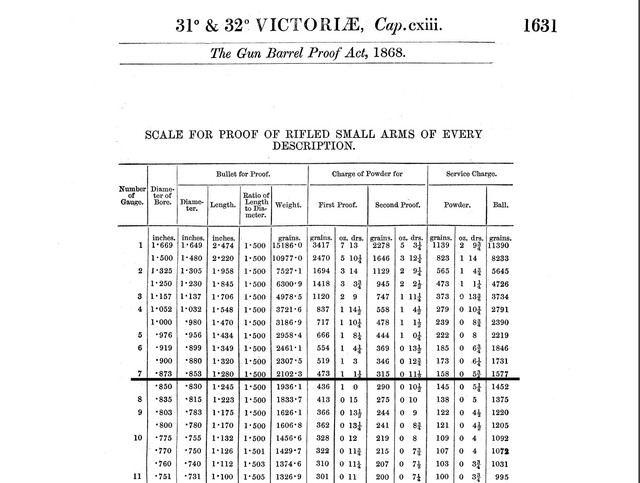

Bore is ~ 7 gauge ( ~0.9”)

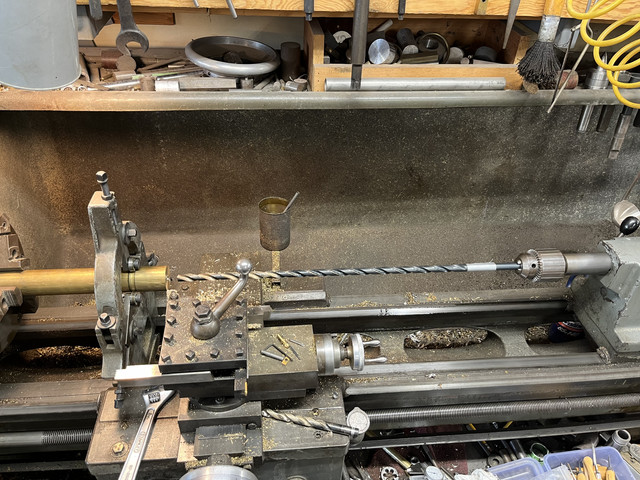

The owner has asked me to make a near bench copy of it. Of course, the barrel is the hardest part to duplicate and I am heading toward machining it myself from bar stock. However, before I get started I wanted to ask this knowledgeable community for an assessment of this piece. This is really the very first original firearm that I have handled directly and it appears to be in excellent condition….at least to my untrained eye.

https://www.muzzleloadingforum.com/threads/blunderbuss.103402/

The fellow who I made this for has contacted me again about a smaller version. He happened across an original blunderbuss that was significantly smaller and lighter than then one I built for him in the link above. Here are some details:

Brass cannon barrel 12.5” long with clear proof & view marks and engraved “LONDON”

Brass mounts in good condition

Lock is marked “NICHOLSON” and is in excellent working condition

Back of the lock marked “IW”

Excellent wood, no cracks and no missing pieces

Bore is ~ 7 gauge ( ~0.9”)

The owner has asked me to make a near bench copy of it. Of course, the barrel is the hardest part to duplicate and I am heading toward machining it myself from bar stock. However, before I get started I wanted to ask this knowledgeable community for an assessment of this piece. This is really the very first original firearm that I have handled directly and it appears to be in excellent condition….at least to my untrained eye.