- Joined

- Mar 7, 2007

- Messages

- 729

- Reaction score

- 2,341

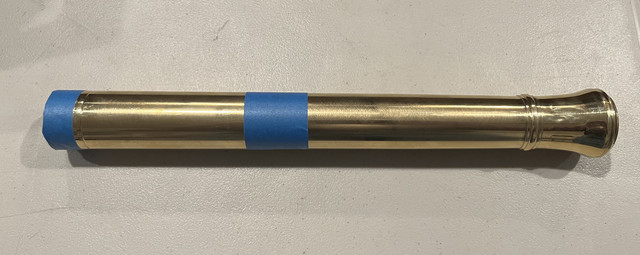

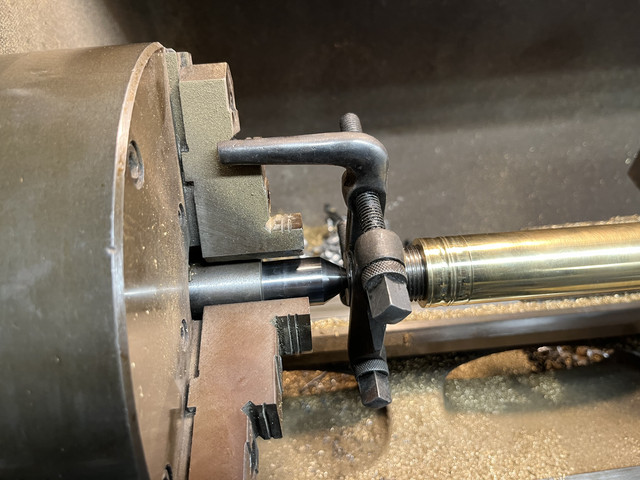

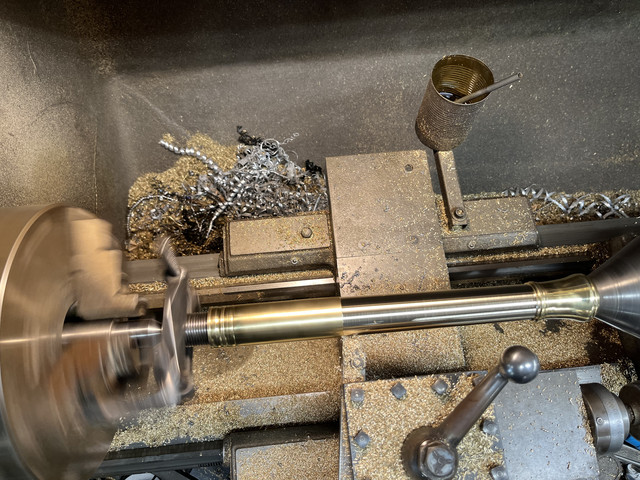

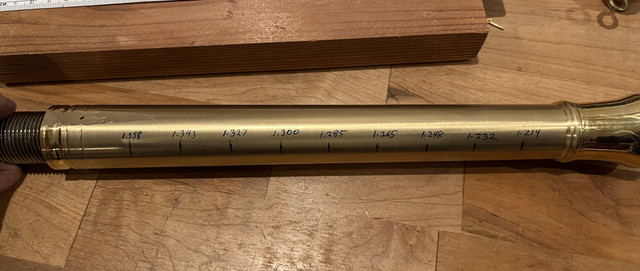

I will need to proof this barrel before I go too far with the build. It is a 7 bore. It's made out of better material than the original (I'm fairly sure) and the bore is slightly smaller (i.e. thicker walls), so it should be fine. However, anyone know what a 7 bore proof charge should be ?

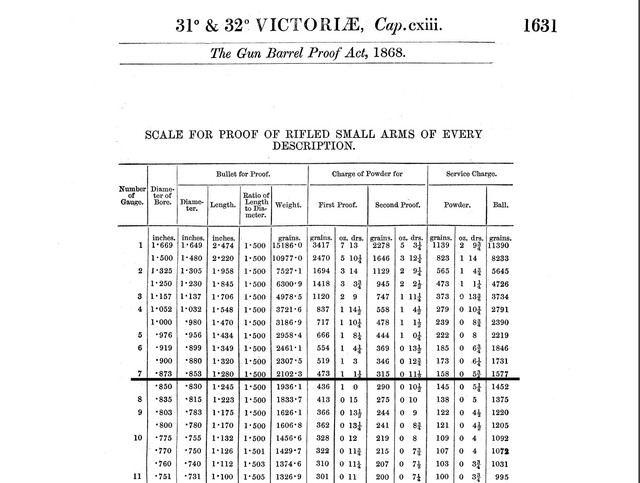

#@!! $#@* !!!! Just found the British Gun Barrel Proof Act of 1868.......here is an excerpt ......

For a 7 bore, look at the powder and projectile weights required for a first and second proof !!!!!! I want to proof the barrel but this looks more like I'm making a pipe bomb !!!

I found an old chart in a 1972 Dixie Gun Works catalog that had some Belgian service and proof charges. The service charge was 158 grains behind a 7 gage round ball but the proof charge was over 500 grains !!! I like the idea of perhaps 180 to 200 grains as the proof charge behind 3 oz of shot for the first proof. Less powder and a little more shot for the second. The barrel is only 12 inches long, so I really don't want to fill it half way with powder and then a load of shot