Most likely, your problem is with the angle of the sear notch and the way it engages the sear.

This angle of the surface on the tumbler and sear really shouldn't be frinkled with unless you know what your doing.

There may be a few things you can look at though.

The locks sear arm is held in place and pivots on the sear screw. I have seen cases where someone was apparently concerned with the screw being too loose so they tightened it up real good. The net result of this is that the sear would just barely move from the spring pressure on the top, or the trigger from the bottom.

With the lock uncocked, check to see that the sear moves freely against up and down against the spring load. If it doesn't loosen the screw just a little until it does move easily.

The tumbler notch and the nose (end) of the sear should be very smooth surfaces. If they are rough, the sear nose will not slide easily across the notch surface.

Some people take a very fine grinding (whet) stone and try to smooth the surfaces. While this can be done, it is not without it's dangers.

If the angle of these surfaces is changed by overuse of the grinding stone it can make the lock and gun a hazard because the sear can slip releasing the hammer all by itself.

If you have access to a buffing wheel, the surfaces can be buffed using "stainless" compound (or equivalent) to get a mirror like surface.

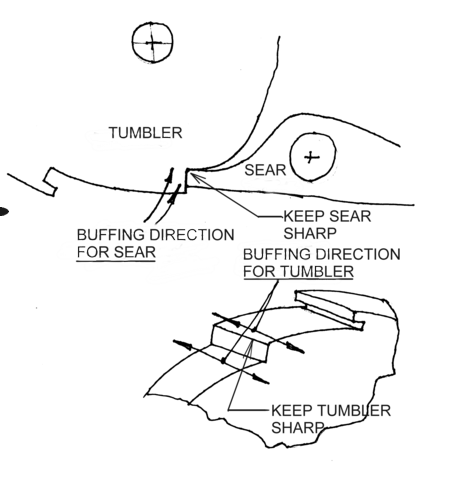

This also should be done with the buffing done only in the direction shown in these sketches:

Note that the direction of buffing is always in a direction that will not round off the critical sharp edges.

This buffing will remove less than .001 of the material which is often enough to really smooth out the lock but it will not change the critical angles or remove the sharp edges.