I received a 70's underhammer H&A the other day and it has a crack lengthwise throughout the forearm. The crack could be repaired but on top of this a williams peep was tapped into the side of the barrel at some point and a few inches of the forearm was cut away to accomodate it. So to get the rifle back to a more traditional form, the peep will be removed and original type sights reinstalled on the barrel. I was thinking i'd just file the peeps screws off flush with the barrel flat and polish both spots, then brown the metal. The forearm replacement, is a bit more daunting to me, as i'm not sure how to get the 2 forearm pins location marked exactly in the right place on the wood before drilling. Any tips on how to accomplish this? Thanks! Jeff

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aligning stock pins

- Thread starter JonnyReb3

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Do a search here. There is a company that sells H&A parts or a remake of them.

I've got a replacement from Numrich on the way supposedly but its for a slightly different rifle.. a heritage model, mines the buggy. I'm figuring there won't be pin holes predrilled, or if so they won't line up right. For $22.00 i'm not complaing but will have to figure out those pins. Then again it might pop right together. J

Measure, mark, measure, mark, measure again, then measure some more.

Basically, you want to put marks on the sides of the barrel where the hole is, transfer those marks onto the stock as vertical lines. Then, measure the distance from the top of the barrel to the hole in the lug, put the barrel back in the stock, and transfer that measurement to the stock. You should now have a cross on the side of the stock in the exact place where the hole in the lug is. Do this on both sides for both pin holes, re-measure and check, then drill.

Basically, you want to put marks on the sides of the barrel where the hole is, transfer those marks onto the stock as vertical lines. Then, measure the distance from the top of the barrel to the hole in the lug, put the barrel back in the stock, and transfer that measurement to the stock. You should now have a cross on the side of the stock in the exact place where the hole in the lug is. Do this on both sides for both pin holes, re-measure and check, then drill.

Thanks M ford, thats what i was afraid of :grin:

I was hoping for a magic trick to make it simple and more foolproof but it is what it is. Obviously one only needs to get one side done correctly then align through the barrels pin holes to mark the other side. I was thinking maybe a slightly undersized and shortened pin with some pipe dope on one end, insert the pin in the barrel lugs and slide the stock on the barrel, turn it sideways and hope the pin might slide to the wood, marking it with the white paste. Just a thought. J

I was hoping for a magic trick to make it simple and more foolproof but it is what it is. Obviously one only needs to get one side done correctly then align through the barrels pin holes to mark the other side. I was thinking maybe a slightly undersized and shortened pin with some pipe dope on one end, insert the pin in the barrel lugs and slide the stock on the barrel, turn it sideways and hope the pin might slide to the wood, marking it with the white paste. Just a thought. J

Got a drill press?

Get the barrel and pin location to line up with the bit in your press with a drill press vice/clamp or jig of some sort,,

then put the forearm on the barrel and put the barrel back in the same position,, :hmm:

Get the barrel and pin location to line up with the bit in your press with a drill press vice/clamp or jig of some sort,,

then put the forearm on the barrel and put the barrel back in the same position,, :hmm:

There really aren't any shortcuts, and it's not that bad really. Just measure twice, cut once, and you'll be fine. I did all of mine on my Lancaster build with a hand drill eyeballing it. Got my wife to get down to eye level and make sure I was square that direction, while I looked down from above to make sure I was square that way, and they went right in perfectly. I had to do 4 of them... and all 4 had different measurements due to the swamped barrel! Went off without a hitch. You can do it!

You make it sound easy :shocked2:

These are little 1/4" brass pins with corresponding holes drilled right through the barrel, no actual lug .If i'm off even a smidgen then the stock will be free floated from the barrel, i have to be EXACT, and i'm not an "exact" kinda guy plus my wife would purposely tell me "THERE!" in the wrong spot

plus my wife would purposely tell me "THERE!" in the wrong spot Ask me how i know.

Ask me how i know.

Necchi , i see what you mean, if i have a very stable jig on my press, aligned just so.. then then add the wood, it would be an exact perfect lineup and should work great. Thanks i can do this. :thumbsup:

These are little 1/4" brass pins with corresponding holes drilled right through the barrel, no actual lug .If i'm off even a smidgen then the stock will be free floated from the barrel, i have to be EXACT, and i'm not an "exact" kinda guy

Necchi , i see what you mean, if i have a very stable jig on my press, aligned just so.. then then add the wood, it would be an exact perfect lineup and should work great. Thanks i can do this. :thumbsup:

jdkerstetter

69 Cal.

- Joined

- Feb 15, 2012

- Messages

- 3,029

- Reaction score

- 7

1/4" pins holes drilled through the barrel, without lugs???? How heavy a barrel is this???? How thick are the walls???? How much barrel wall are you expecting to leave between the pins and the bore????

Something just doesn't add up. Enjoy, J.D.

Enjoy, J.D.

Something just doesn't add up.

H&A drilled through the barrel at 2 locations for the pins. The ramrod was fitted real close to the barrel and the underrib was very thin. It might be possible to solder or dovetail lugs under the barrel but they could not be as deep as you are accustomed to in the typical rifle. I have to leave for work in a few minutes or I would measure my H&A buggy rifle. An alternative would be to plug the holes and leave the forearm off, a lot of New England underhammers were built that way.

If I was doing this chore the very first thing I would look at is, "How thick is the wood between the barrel channel and the bottom of the forearm?"

If there was any possibility of cutting a couple of small mortices to clear some 3/16" tall underlugs without breaking thru the bottom of the wood, that's the way I'd go.

It's pretty easy to dovetail a couple of underlugs in place, cut the clearance mortices into the bottom of the barrel channel in the forearm and then drill a couple of 5/64 or 3/32 inch holes for the pins.

If using the existing pin holes is the only answer, a fixture to hold the barrel securely to a drill press table is the other way.

The fixture must totally clear the area where the forearm will be but must clamp the barrel.

With the barrel mounted into the fixture, both are moved around on the drill press table until one hole is perfectly aligned with the center of the chuck. Then it is clamped in place.

With the barrel located and clamped, the forearm is then put in place on the barrel and clamped with a spring or C clamp. The hole is then drilled thru the wood.

If everything was done right, the drill bit will pass freely thru the hole in the barrel and will then proceed to drill thru the other side of the forearm.

After this is done, the whole setup is then moved to align the other hole in the barrel with the chucks centerline.

Again, put the forearm back on the barrel and run a pin thru the previously drilled hole.

Spring or C clamp the loose end of the forearm to the barrel and drill the second hole.

This whole thing is a PITA with a home workshop but it can be done if enough profanity is used.

If there was any possibility of cutting a couple of small mortices to clear some 3/16" tall underlugs without breaking thru the bottom of the wood, that's the way I'd go.

It's pretty easy to dovetail a couple of underlugs in place, cut the clearance mortices into the bottom of the barrel channel in the forearm and then drill a couple of 5/64 or 3/32 inch holes for the pins.

If using the existing pin holes is the only answer, a fixture to hold the barrel securely to a drill press table is the other way.

The fixture must totally clear the area where the forearm will be but must clamp the barrel.

With the barrel mounted into the fixture, both are moved around on the drill press table until one hole is perfectly aligned with the center of the chuck. Then it is clamped in place.

With the barrel located and clamped, the forearm is then put in place on the barrel and clamped with a spring or C clamp. The hole is then drilled thru the wood.

If everything was done right, the drill bit will pass freely thru the hole in the barrel and will then proceed to drill thru the other side of the forearm.

After this is done, the whole setup is then moved to align the other hole in the barrel with the chucks centerline.

Again, put the forearm back on the barrel and run a pin thru the previously drilled hole.

Spring or C clamp the loose end of the forearm to the barrel and drill the second hole.

This whole thing is a PITA with a home workshop but it can be done if enough profanity is used.

mikemeteor

45 Cal.

- Joined

- Nov 16, 2008

- Messages

- 660

- Reaction score

- 3

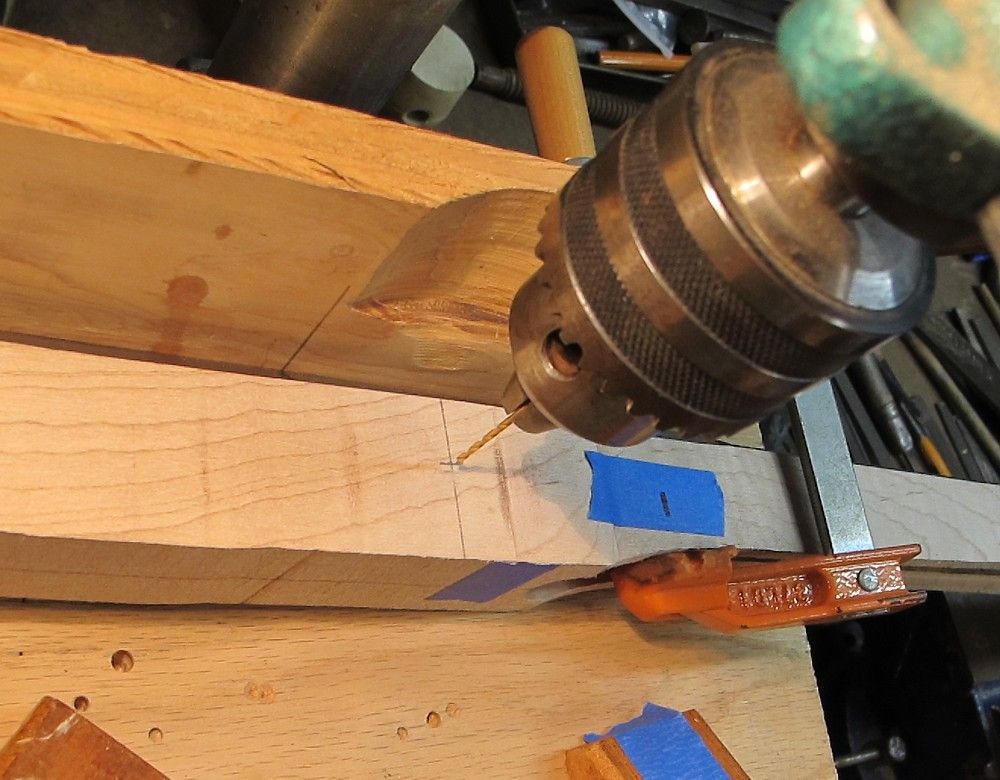

some pics of the drill press technique being described here.

Pic 1: (Left) lining the drill bit up on the bare barrel, exactly where you want it to pass. (Right) And marking the barrel position on your jig, so you can put it back in the exact same spot, after you put the wood on.

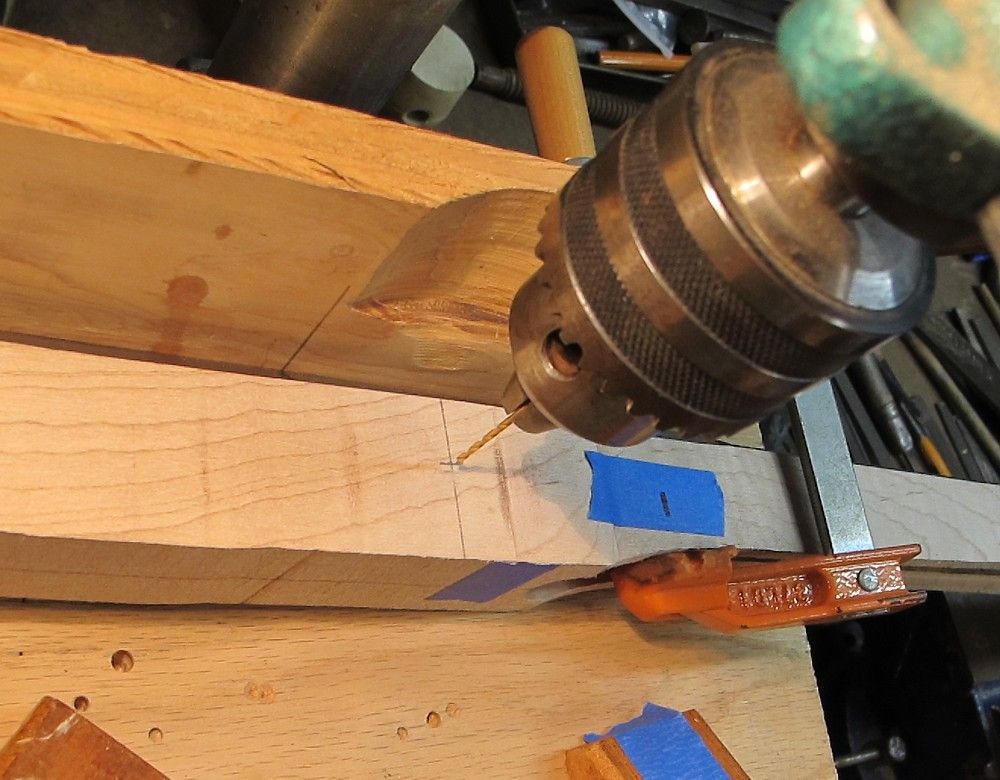

Pic 2: Put the wood on and return to exact previous spot, on the jig. Level it up with shims if necessary. Clamp firmly !

Pic 3: what the whole mess looks like on my little benchtop drill press.

This is where the generous profanity that Zonie cites comes in handy.

And if you don't clamp firmly and something tips on you slightly, and snaps that skinny little drill bit off in the wood, you will discover a whole new vocabulary that you didn't know you had.

But, I have to say, done carefully, it works every time.

/mike

Pic 1: (Left) lining the drill bit up on the bare barrel, exactly where you want it to pass. (Right) And marking the barrel position on your jig, so you can put it back in the exact same spot, after you put the wood on.

Pic 2: Put the wood on and return to exact previous spot, on the jig. Level it up with shims if necessary. Clamp firmly !

Pic 3: what the whole mess looks like on my little benchtop drill press.

This is where the generous profanity that Zonie cites comes in handy.

And if you don't clamp firmly and something tips on you slightly, and snaps that skinny little drill bit off in the wood, you will discover a whole new vocabulary that you didn't know you had.

But, I have to say, done carefully, it works every time.

/mike

matt denison

54 Cal.

- Joined

- Aug 15, 2004

- Messages

- 1,786

- Reaction score

- 14

How about just ignore the existing holes and drill new ones through the wood and barrel. That would save having to hit the existing hole within .001".

Similar threads

- Replies

- 49

- Views

- 5K

- Locked

- Replies

- 20

- Views

- 3K

- Replies

- 3

- Views

- 1K