Way back in my military days, those big, expensive, Rambo-style knives were all the rage. All the guys were shopping catalogs and saving money for a Jimmy Lile or a Randall custom, or at least something along those lines. I was discussing this one evening with one of the old grizzled Vietnam-era SF instructors, who had survived three tours over there and was deeply respected by all of us younger fellows as a result. I remember him commenting not on the pride of ownership or the quality of the steel but instead, of utility and indifference. He said those custom $500 knives looked pretty cool in the barracks but when you'd just dropped ruck, called in Puff, and opened an E&E corridor, that $500 piece of dead weight on your LBE was gonna be just that: dead weight. All through Vietnam, he'd carried a cut down USMC Kabar. Its blade was about an inch shorter than original, trimmed down the length of its spine, and fitted with a lighter leather sheath. Every piece of his gear was like that. If it had some extra heft or otherwise superfluous aspect to it, he'd ground/cut/trimmed it away to save weight and space. His load out was probably 25lbs lighter than anyone else's and he could've probably outlasted any of us in Indian country two to one! Sgt. Wyatt's concept of MBP (Most-Base Parameters) in regards to choosing personal equipment has stuck with me all these years. What's the minimum mass that will do the job? What's the cheapest option that will do the job? What he was getting at is that all this state-of-the-art, custom crap will end up frying your bacon when the SHTF. Cheap, yet serviceable equipment will do the job, yet you can drop it trailside and run for your life with no reservations, if need be. Make sense? It does to me and much of my gear is based on that simple concept. You're not apt to drop your $**** Frank House one-of-a-kind, hand made, God Almighty original 'hawk in the forest and run for your life till you make the fort, now are you? In that vein, I share with you my cheapahawk...

I found a basic 'hawk today in the black powder aisle at my local Cabela's. First of all, I was absolutely flabbergasted one could by a 'hawk of any kind in a common retail establishment like this! Second, I was more than a little astonished to find it priced at only $24. Following are the details of what I did to this cheap, commonly available 'hawk to make it mine.

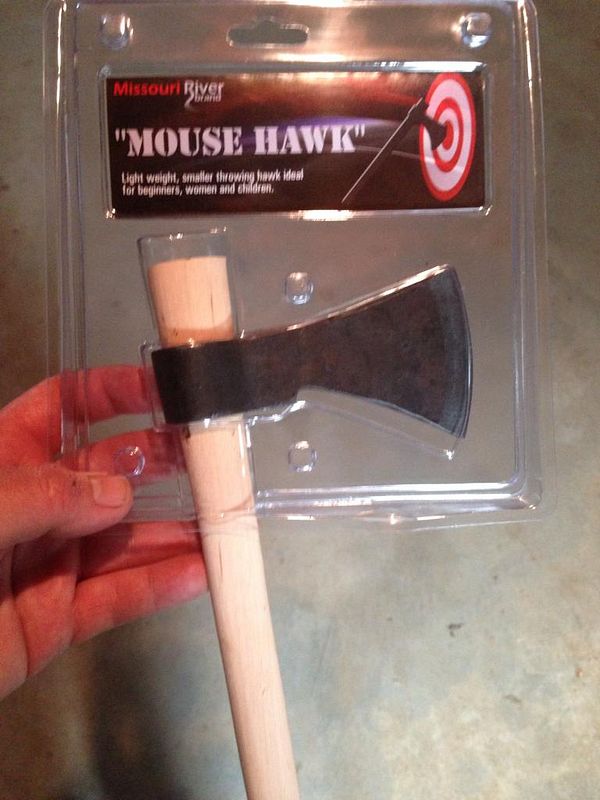

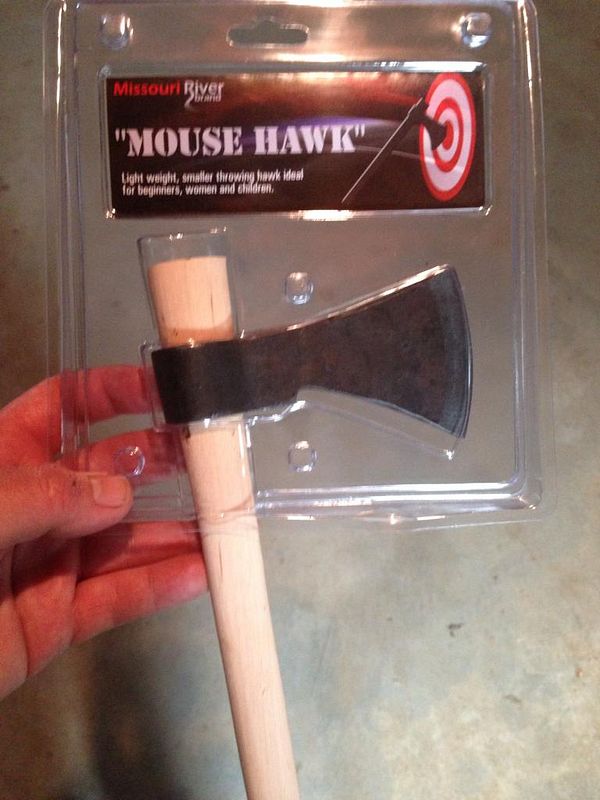

As packaged for Cabela's, in all it's Indian (as in, Made In India) glory. This is what you'll see hanging on the pegboard rack if you go looking for it:

The first thing to correct is the machine centers. I used my belt knife to whittle these thoroughly modern indentations into nonexistence. Before:

And after:

Next, I wrapped some cotton mason's twine around the hickory (?) handle in as irregular fashion as I could manage:

Using a propane torch turned way down low, I scorched the handle until realizing a pleasant pattern, taking care to neither burn the twine in two, nor get the handle hotter than what could be comfortably held in hand:

Removing the scorched twine and rubbing in a bit of walnut-hull dye reveals this effect to the wood:

The blade as it comes from the package would be hard pressed to stick in a bale of straw! As this so-called “mouse hawk” is marketed to women and children, its edge is insufficient for hacking through even a poorly-constructed meatloaf. It makes good sense from a product liability standpoint, but we'll need something MUCH better than the coathanger edge supplied from the manufacturer:

Some dressing with a file followed with some proper stoning will reveal a very adequate edge. Not shaving sharp, as we won't be shaving with our 'hawk, but more than adequate for camp and fighting duties. From the metalworker's point of view, this head feels much like an annealed AISI 4140 under the file. Perfectly sufficient for my intended purposes:

Here's the semi-finished product. Several coats of linseed oil will finish it out and a sheath will need to be made, but you can get the gist of things from this, I hope. A good, serviceable belt 'hawk for a very modest outlay of funds is a thing to be shared, I'm thinking. I'll post pics of the sheath as soon as that comes to be. Any similar projects out there? Please post thoughts and photos if you have them!

I found a basic 'hawk today in the black powder aisle at my local Cabela's. First of all, I was absolutely flabbergasted one could by a 'hawk of any kind in a common retail establishment like this! Second, I was more than a little astonished to find it priced at only $24. Following are the details of what I did to this cheap, commonly available 'hawk to make it mine.

As packaged for Cabela's, in all it's Indian (as in, Made In India) glory. This is what you'll see hanging on the pegboard rack if you go looking for it:

The first thing to correct is the machine centers. I used my belt knife to whittle these thoroughly modern indentations into nonexistence. Before:

And after:

Next, I wrapped some cotton mason's twine around the hickory (?) handle in as irregular fashion as I could manage:

Using a propane torch turned way down low, I scorched the handle until realizing a pleasant pattern, taking care to neither burn the twine in two, nor get the handle hotter than what could be comfortably held in hand:

Removing the scorched twine and rubbing in a bit of walnut-hull dye reveals this effect to the wood:

The blade as it comes from the package would be hard pressed to stick in a bale of straw! As this so-called “mouse hawk” is marketed to women and children, its edge is insufficient for hacking through even a poorly-constructed meatloaf. It makes good sense from a product liability standpoint, but we'll need something MUCH better than the coathanger edge supplied from the manufacturer:

Some dressing with a file followed with some proper stoning will reveal a very adequate edge. Not shaving sharp, as we won't be shaving with our 'hawk, but more than adequate for camp and fighting duties. From the metalworker's point of view, this head feels much like an annealed AISI 4140 under the file. Perfectly sufficient for my intended purposes:

Here's the semi-finished product. Several coats of linseed oil will finish it out and a sheath will need to be made, but you can get the gist of things from this, I hope. A good, serviceable belt 'hawk for a very modest outlay of funds is a thing to be shared, I'm thinking. I'll post pics of the sheath as soon as that comes to be. Any similar projects out there? Please post thoughts and photos if you have them!